Lull 6K Service Manual User Manual

Page 178

Supply, Pressure, and Return Hydraulics

5-34

Service Manual — Models 644B, 6K, 844C, 8K, 1044C, 10K

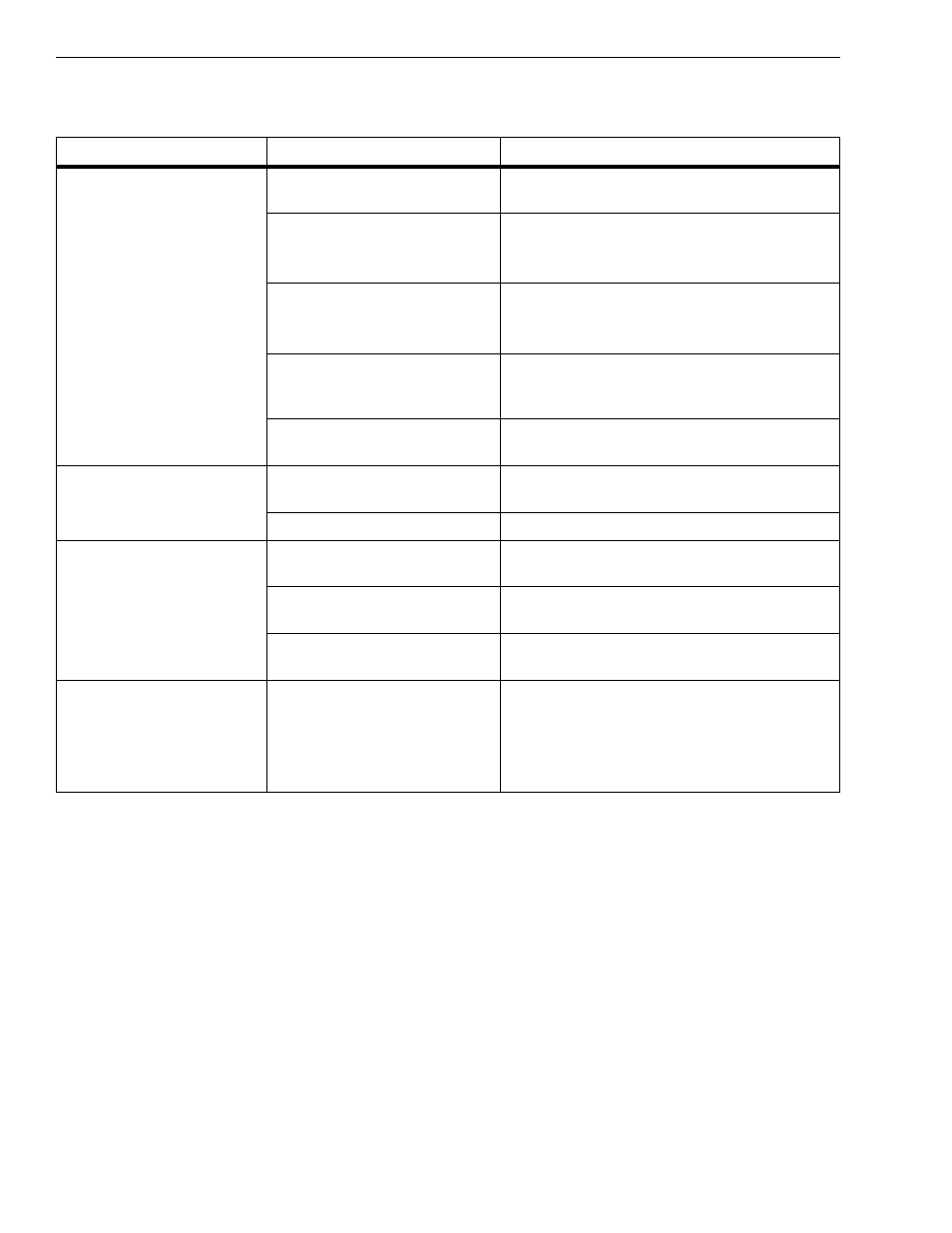

Troubleshooting Pump Problems

Problem

Probable Cause

Solution

1. Excessive pump noise

A. Low oil level in the hydraulic

reservoir

Fill reservoir to proper level with the recommended

hydraulic fluid. DO NOT overfill.

B. Air in the system

1. Operate hydraulic system until purged.

2. Check inlet (suction) lines and fittings for air

leaks.

C. Vacuum condition

1. Check inlet (suction) lines and fittings for

restrictions.

2. Check reservoir breather filter conditions.

D. Oil too thick

Be certain correct type of oil is used for refilling or

adding to the system. Viscosity must be correct for

ambient temperatures.

E. Cold weather

Run hydraulic system until unit is warm to the

touch and noise disappears. Check oil viscosity.

2. Pump Overheating

A. Internal leakage

Return vehicle to maintenance shop for evaluation

and repair.

B. Low fluid level

Add oil to operating level.

3. System not developing

pressure

A. Relief valve open

Replace or repair the relief valve.

B. Loss of fluid internally

(slippage)

Return the vehicle to the maintenance shop for

repair of hydraulic system.

C. Disconnected or broken pump

drive

Inspect and repair or replace.

4. Loss of fluid

A. Ruptured hydraulic lines

B. Loose fittings

C. Leaking gaskets or seals in

pump or circuit

1. Check all external connections, tubing, and

hoses. Tighten connections and replace any

ruptured tubes or hoses.

2. Observe mating sections of pump for leaks.

3. Replace seals or gaskets if possible.