IAI America MSCON User Manual

Page 307

Chapter 8

Troubleshooting

299

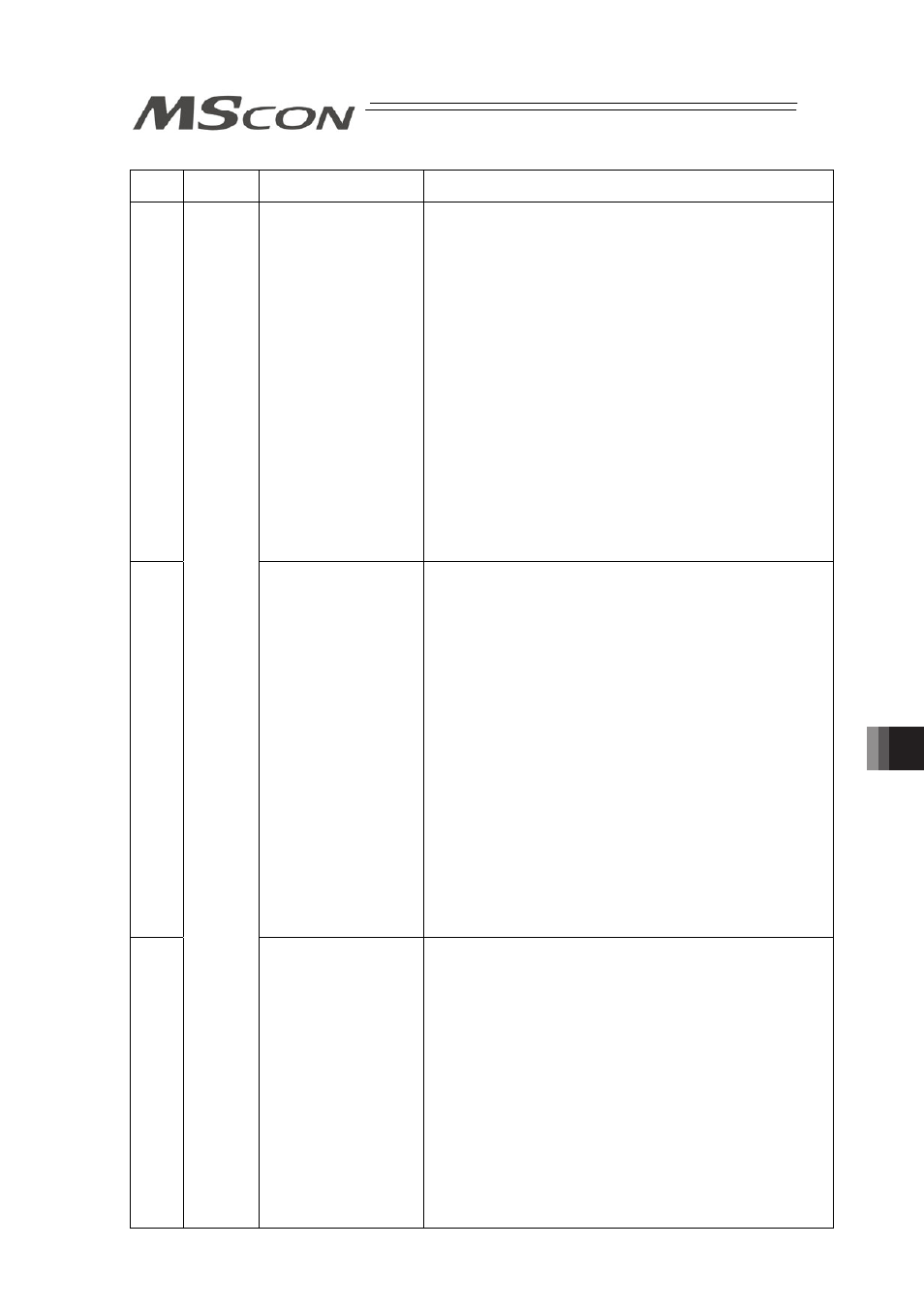

Alarm

Code

Alarm

Level

Alarm Name

Cause/Treatment

0E4

Encoder send error

Cause

: The data sending and receiving between the

controller and encoder is conducted by the serial

communication. This error indicates that the data

sent from the controller was not received properly

at the encoder side.

1) Encoder cable is about to break or connector is

not plugged properly

2) Effect of noise

3) One or more communication ICs installed on the

encoder board are faulty.

4) One or more communication ICs installed on the

controller board are faulty.

Treatment : 1) Check on the cables and the connector joints to

see if any abnormality.

2) Interrupt the power to the peripheral equipment

and activate only the actuator. If any error does

not occur, it might be caused by noise. Take

proper measures against noise.

If 3) or 4) is the case, the encoder or controller must

be replaced. If the cause cannot be specified,

please contact IAI.

0E5

Encoder receipt error

Cause

: This shows the data was not received in normal

condition from the encoder side to the controller.

1) Cable breakage of encoder cable or connector

connection failure.

(If the detail code in the error list of the teaching

tool is 0002

H

.)

2) Effect of noise.

(If the detail code in the error list of the teaching

tool is 0001

H

.)

3) Malfunction of component (communication part)

inside the actuator.

4) A faulty part inside the controller (communication

part).

Treatment : 1) Check if any wire breakage on a connector and

the condition of wire connections.

2) Interrupt the power to the peripheral equipment

and activate only the actuator. If any error does

not occur, it might be caused by noise. Take

proper measures against noise.

If 3) or 4) is the case, it is necessary to replace the

actuator (motor part) or controller.

If the cause cannot be specified, please contact IAI.

0E6

Cold start

Encoder count error

Cause

: This error code appears when the encoder cannot

detect the position information properly.

1) The encoder relay cable or supplied actuator

cable is disconnected or its connector is not

plugged in correctly.

2) Foreign matter is deposited on the code wheel.

3) The position relationship between the code

wheel and photo sensor changed due to shaft

center shift caused by application of excessive

external force, etc.

4) Faulty encoder board component

Treatment : 1) Check if any wire breakage on a connector and

the condition of wire connections.

For the case of 2), 3) or 4), it is necessary either to

clean the code wheel, adjust the installation

position, replace the motor unit or replace the

actuator. In any case, please contact IAI.