IAI America MSCON User Manual

Page 303

Chapter 8

Troubleshooting

295

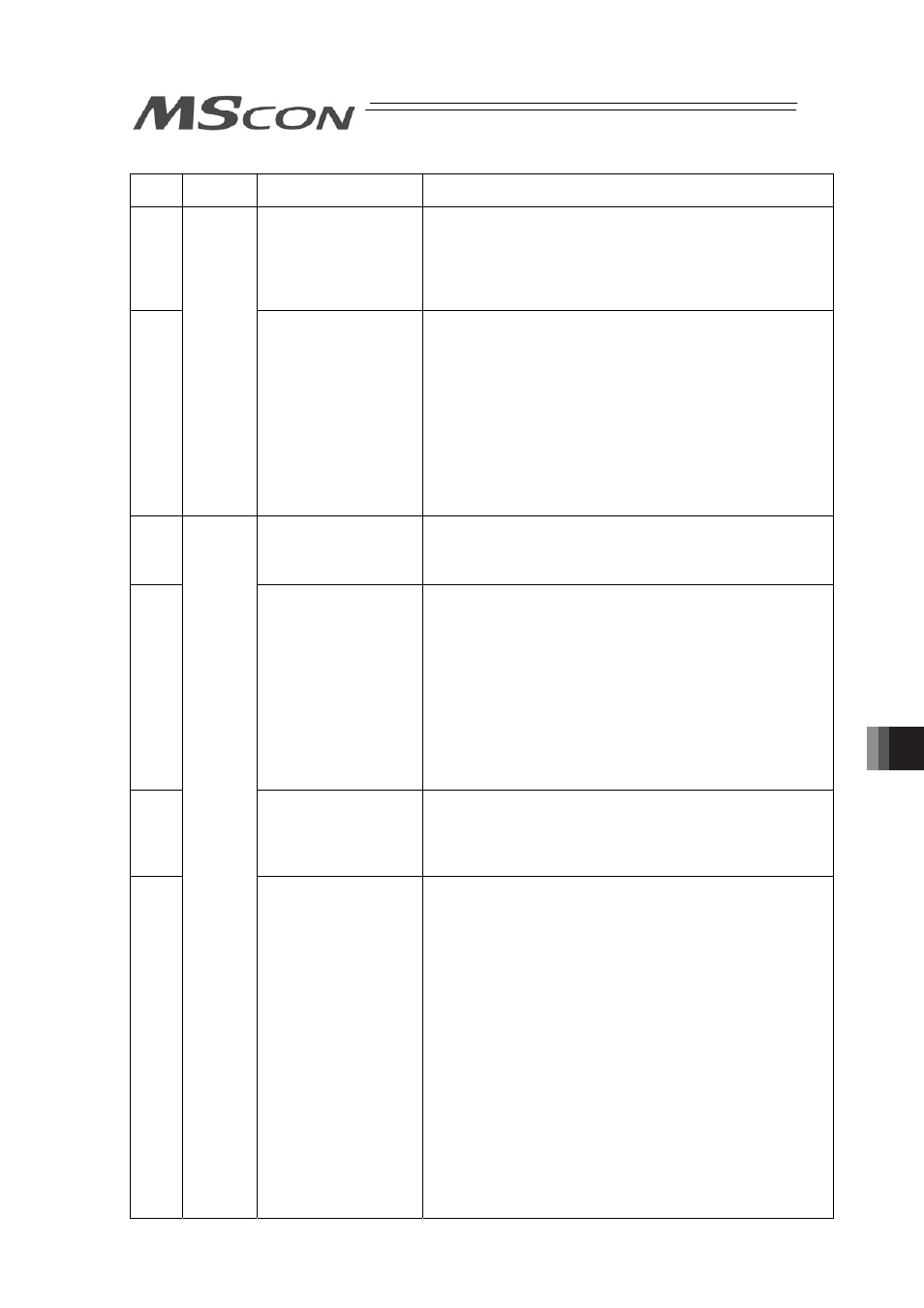

Alarm

Code

Alarm

Level

Alarm Name

Cause/Treatment

0A8

Unsupported

motor/encoder types

Cause

: The motor connected to the controller is not

applicable or the type of the encoder that the motor

is connected is not applicable.

Treatment : Please contact us if the alarm is issued even with

the applicable actuator and the same problem

happens again even after rebooting the power.

0B4

Cold start

Electric angling

mismatching

Cause

: This alarm indicates that the position deviation

counter has overflowed.

Treatment : The alarm occurs when the actuator cannot be

operated.

Confirm about the load conditions, that the work

does not interfere with any object nearby or the

brake has been released, etc.

If the error occurs even when the servo is ON,

breakage of the encoder cable is considered.

Check the cable connection. Please contact IAI if

there is no failure in the cable and connector

connections.

0B5

Z-Phase position error

The position where the Z-phase is detected before the home

return operation, is out of the specified range.

Cause

: Encoder Error

Treatment : Please contact IAI.

0BA

Home sensor

non-detection

Cause

: This indicates that the home-return operation of the

actuator equipped with origin sensor (option except

rotary actuator) is not completed in normal

condition.

1) Work is interfering with peripheral equipment in

the middle of home return.

2) Large slide resistance of the actuator itself

3) Installation failure, breakdown or disconnection

of the home sensor

Treatment : In the case that the work does not interfere with

anything, the cause 2) or 3) is supposed. In such

case, please contact IAI.

0BE

Home return timeout

Cause

: Home return does not complete after elapse of a

certain period after the start of home return.

Treatment : This error does not occur in normal operation. The

combination of the controller and actuator may be

incorrect. Please contact IAI.

0BF

Operation

release Creep sensor not

detected

Cause

: This indicates the actuator detected the creep

sensor (option) before detecting the origin sensor

(option except for rotary actuator), or the actuator

reached the mechanical end (or the actuator cannot

move anymore because the load is too large).

1) The position to apply the creep sensor, which is

moved after the product was delivered, is not

appropriate.

2) The creep sensor is faulty.

3) The cable is disconnected or the connector is not

plugged in properly.

4) The actuator cannot move due to heavy load

caused by interference.

Treatment : 1) Readjust the sensor installation position.

2) Replace the creep sensor.

3) Perform continuity check to see if the connector

is plugged in properly.

4) Check the interference and the transportable

weight and make sure there is no external force

applied.