IAI America MSCON User Manual

Page 151

3.5 Control Signals for PIO Operation

143

3.5 Input and Output Signal Process for Field Network

(1) I/O Signal Timings

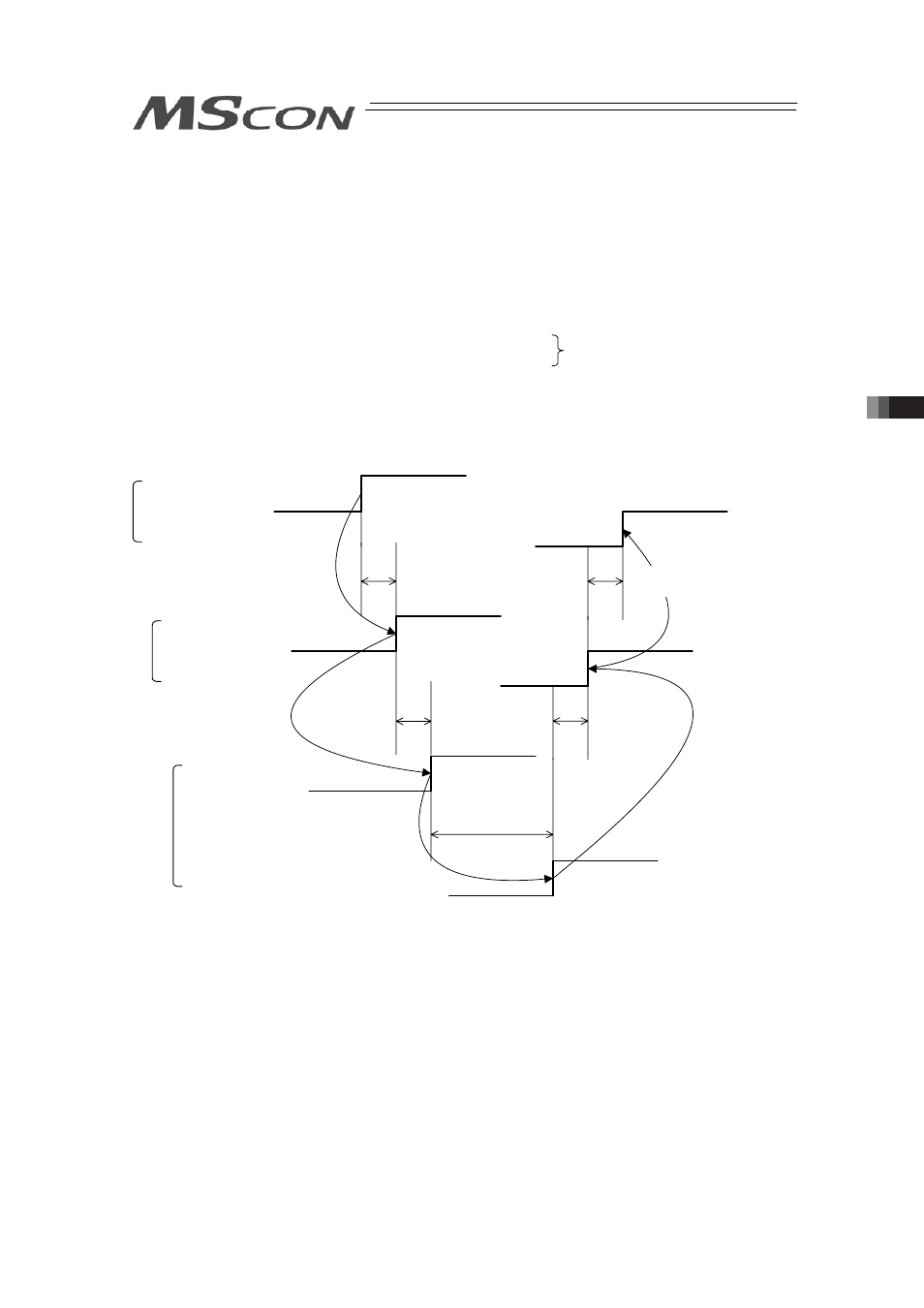

When any of the control signal is turned ON to perform the operation of the robot cylinder using

the PLC's sequence program, the response (status) is returned to the PLC. The maximum

response time is expressed using the following formula.

The value is constant regardless the number of composition axes.

Max. response time (msec.) = Yt + Xt +(3 × Mt) + Response process time (operation time, etc.)

Yt : Master Station ĺ Slave Transmission Delay Time

Xt : Slave ĺ Master Station Transmission Delay Time

Mt = MSCON internal communication sending time (Ttx) + MSCON internal communication

receiving time (Trx)

Refer to the instruction manual of the mounted PLC for the master station ĺ slave transfer

delay time (Yt) and the slave ĺ master station transfer delay time (Xt).

Master → Remote I/O Station

Transmission Delay Time (Yt) *1

Response Process

Time *2

PLC Sequence Program

Control Signal

Status Signal

Gateway

Control Signal

Status Signal

Controller

Control Signal

Status Signal

*1 Refer to PLC Manual

*2 Varies depending on the content of control

Remote I/O Station → Master

Transmission Delay Time (Xt) *1

Ttx to Mt+Ttx

Trx to Mt+Trx

Mt = max.10ms

(data being processed at once for six axes)

Field Network Transmission Delay Time