IAI America MSCON User Manual

Page 305

Chapter 8

Troubleshooting

297

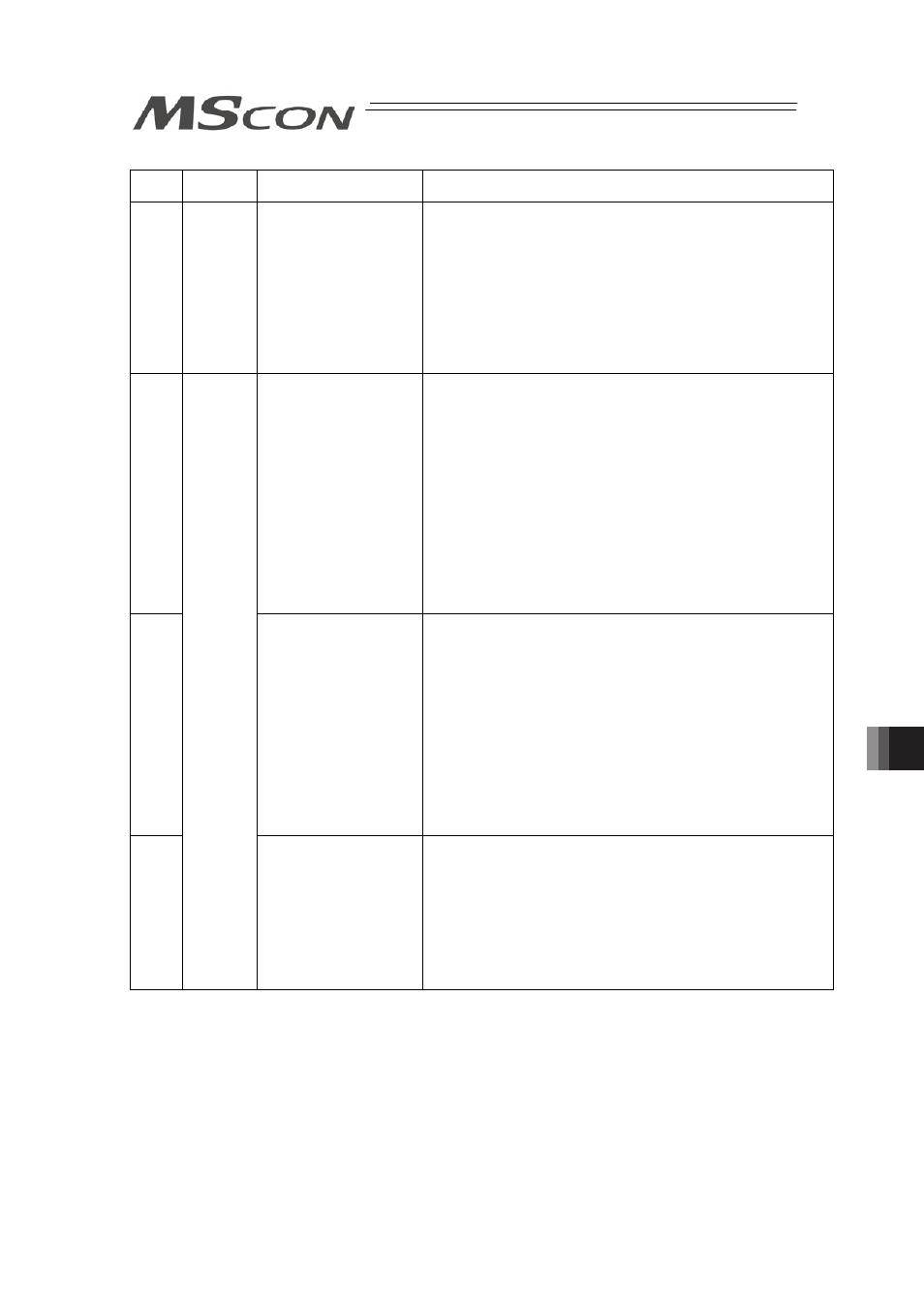

Alarm

Code

Alarm

Level

Alarm Name

Cause/Treatment

0C5

Operation

release

Illegal transition

command in control

system

Cause

: 1) Change the operation from the vibration

suppress control operation to the normal position

control operation.

2) Change the operation from the normal position

control operation to the vibration suppress

control operation.

Treatment : Change the sequence so the next action is

conducted after confirming the positioning complete

signal (PEND) is turned ON for both cases 1) and

2).

0C8

Overcurrent

Cause

: The output current in the power circuit section is

increased abnormally.

Treatment : This alarm will not be generated in normal

operation.

1) Degradation of motor coil insulation

2) Malfunction of components inside controller

can be concerned.

Check if there is deterioration in the insulation by

measuring the phase resistance between the

monitor connection lines U, V and W. The values for

the phase resistance should be almost the same.

There is a concern the insulation is deteriorated if

the values are different in large amount. Please

contact IAI.

0CA

Overheated

Cause

: This indicates overheat (75qC or more) of the

components inside the controller.

1) Operation is performed with the load condition

exceeding the specified range.

2) High temperature around the controller.

3) A faulty part inside the controller.

Treatment : 1) Revise the operation condition such as

decreasing the acceleration/deceleration speed.

2) Lower the ambient temperature of the controller.

(Note) This error would not normally occur. If it occurs, confirm

there is not 1) or 2) above. If the same error is issued

again even after confirming 1) or 2) is not in the condition,

it is considered to be a malfunction. Please contact IAI.

0CB

Cold start

Current sensor offset

adjustment error

Cause

: An error was found to the sensor in the status check

of the current detection sensor conducted at the

initializing process in the startup.

1) The current detection sensor or any of its

surrounding parts is faulty.

2) The actuator has moved with external force

when the power was turned ON.

Treatment : It is necessary to replace the PCB if it occurs even

after rebooting the power. Please contact IAI.