KEYENCE DV-90 User Manual

Page 16

1-4

E DV-90-IM

1

Getti

ng Started

1-2 Overview of DV-90 Functions

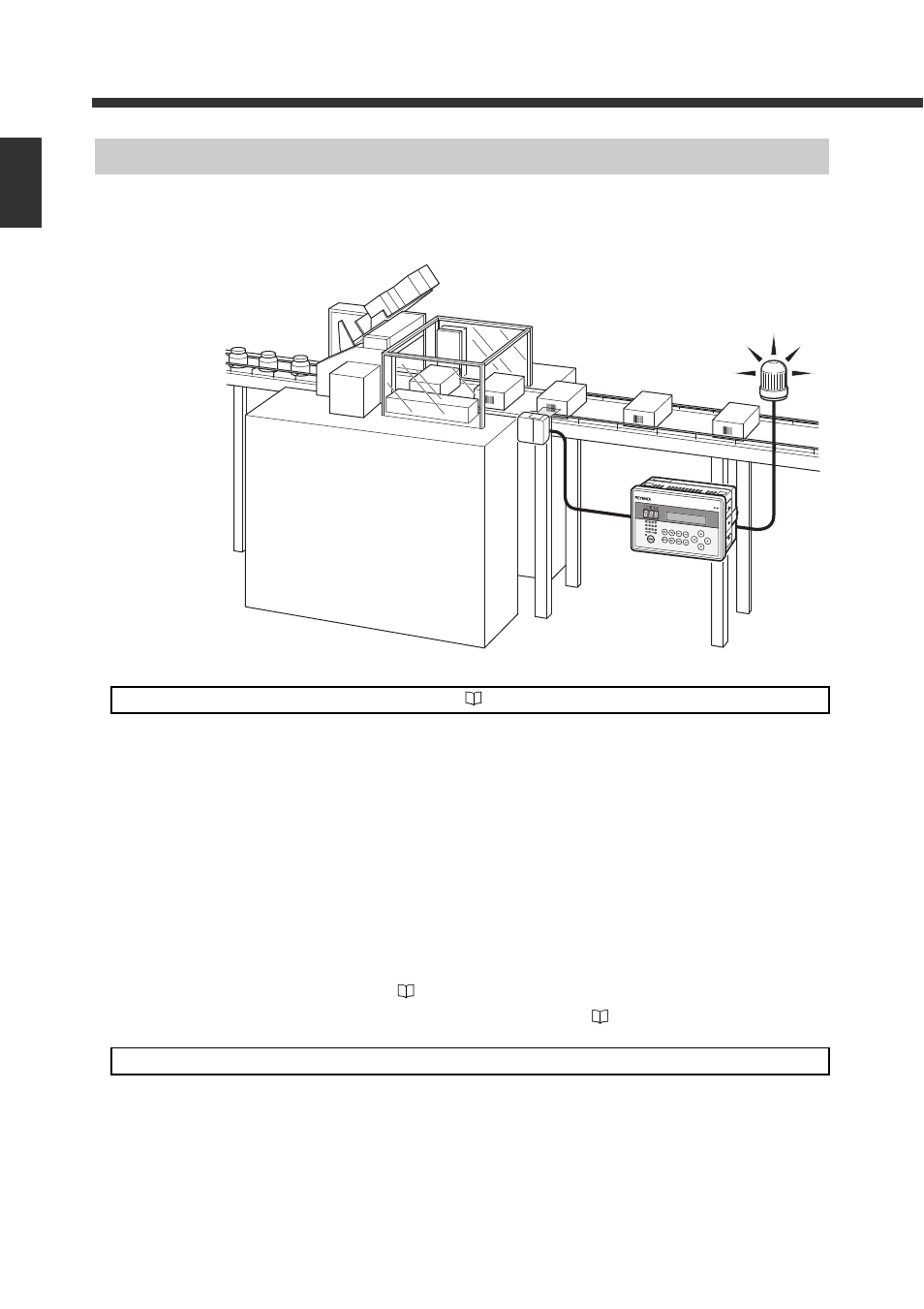

Preventing Mixing with Other Products at a Packaging Machine

By reading the barcode printed on carton cases or cardboard cases at a packaging machine (carton

packing machine or cardboard caser), the mispackaging of products in the wrong box can be pre-

vented.

Use the “Active Verification” function.

Refer to 4-13

Up to 900 presets can be registered beforehand in the DV-90 as master data. The user selects a pre-

set (the “active” record) for the particular line. When a product is scanned with a code reader, the

data is compared to the active preset. A match turns on the OK output. Otherwise, the NG output is

activated.

In the above figure, the barcodes printed on all the carton cases to be used are preset, and the carton

case to be used for the next packaging is selected from among them. If the barcode of the selected

carton case and the actually read barcode do not match, a lamp or buzzer notifies the operator that a

wrong carton case is present.

An active record can be selected by any of the following methods:

• The DV-90 front panel buttons

• Reading the barcode you want to select

• From a PLC (PLC link

⇒

Refer to 9-4)

• Sending commands from a PC (Serial communication

⇒

Refer to 8-11)

Other uses

• Preventing mixing with other products at a labeling machine

Whether the correct label is attached to the product on a labeling machine can be checked.

• Preventing mixing of other products at a filling machine

On a filling machine that fills beverages, cosmetic creams, or seasonings, whether the content is

filled in the correct container can be checked.