14 print-mark register, Print-mark register -85, Cross cutter – Lenze EVS93xx CrossCutter User Manual

Page 99

Cross Cutter

Features of the "Cross Cutter" prepared solution

Prepared Solution Servo PLC / ECSxA 1.1 EN

2-85

2.5.14 Print-mark

register

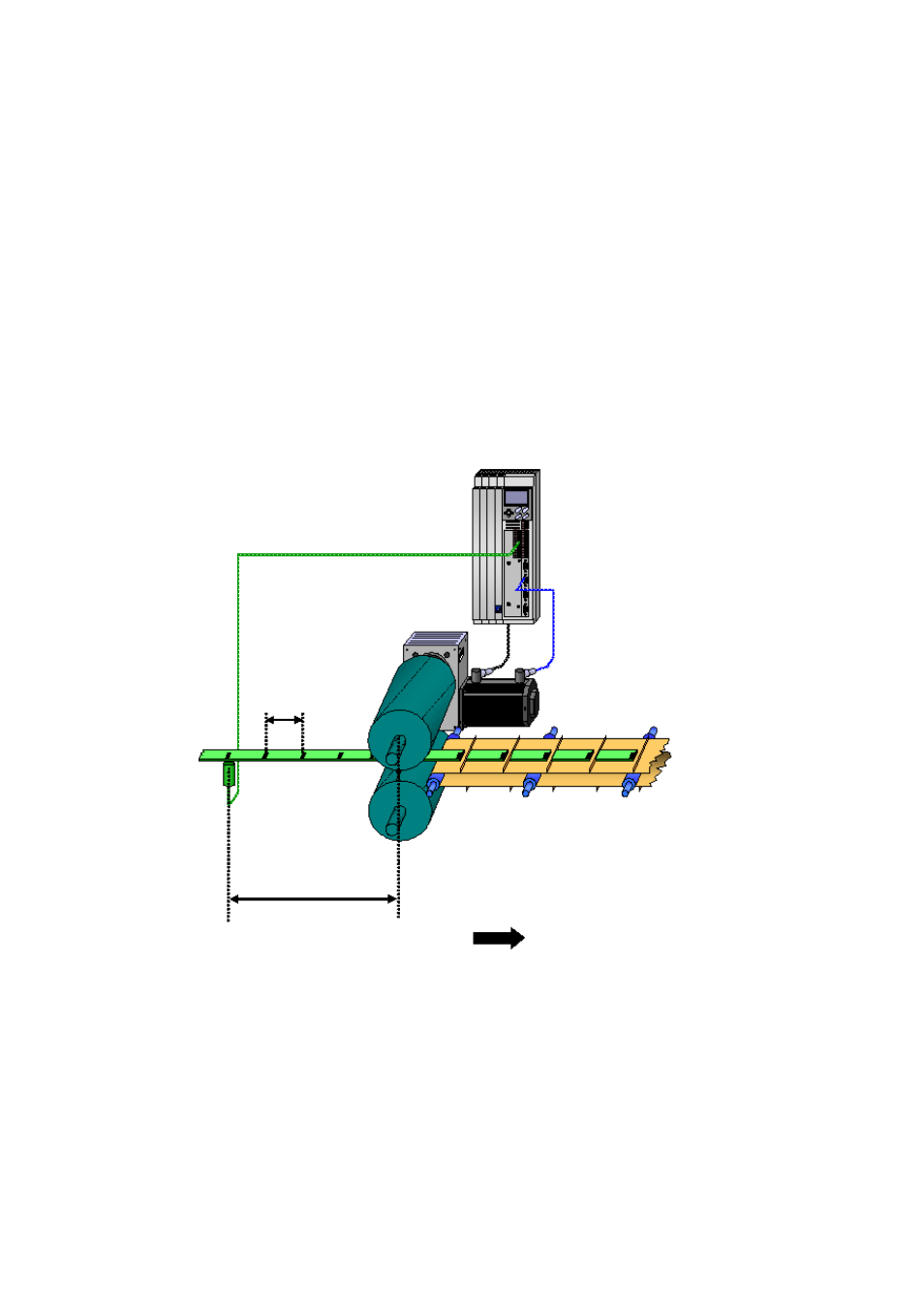

A print-mark register enables the user to mount the print-mark sensor further away from the

knife. As soon as the distance between the location of the print-mark sensor and the end of the

cut (X

max

value of profile) exceeds the cutting length, the print-mark register will need to be used

to make sure that the cut is always corrected to the right print-mark signal. However, the aim

should be to mount the print-mark sensor as close as possible to the knife. The greater the

distance between the print-mark sensor and the knife, the more changes in the material flow will

go unnoticed, leading to cutting inaccuracies. Up to 16 print-mark signals can be managed in

the print-mark register; these are then made available to the system at the relevant time as

necessary (i.e. they are delayed by a corresponding value). The print-mark register is activated

automatically by the prepared solution and receives all necessary information via internal

signals. The user does not need to enter any values.

Figure 35: Using the print-mark register

Figure 35 shows that a print-mark register is always used whenever the distance from the print-

mark sensor to the cross-cutter knife is greater than the set cutting length.

Cutting length Δs

The distance from the TP sensor to the 6 o'clock position on the knife Δl

is greater than the cutting length Δs.

You need to use a TP register!