Cross cutter, Appendix – Lenze EVS93xx CrossCutter User Manual

Page 231

Cross Cutter

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

6-63

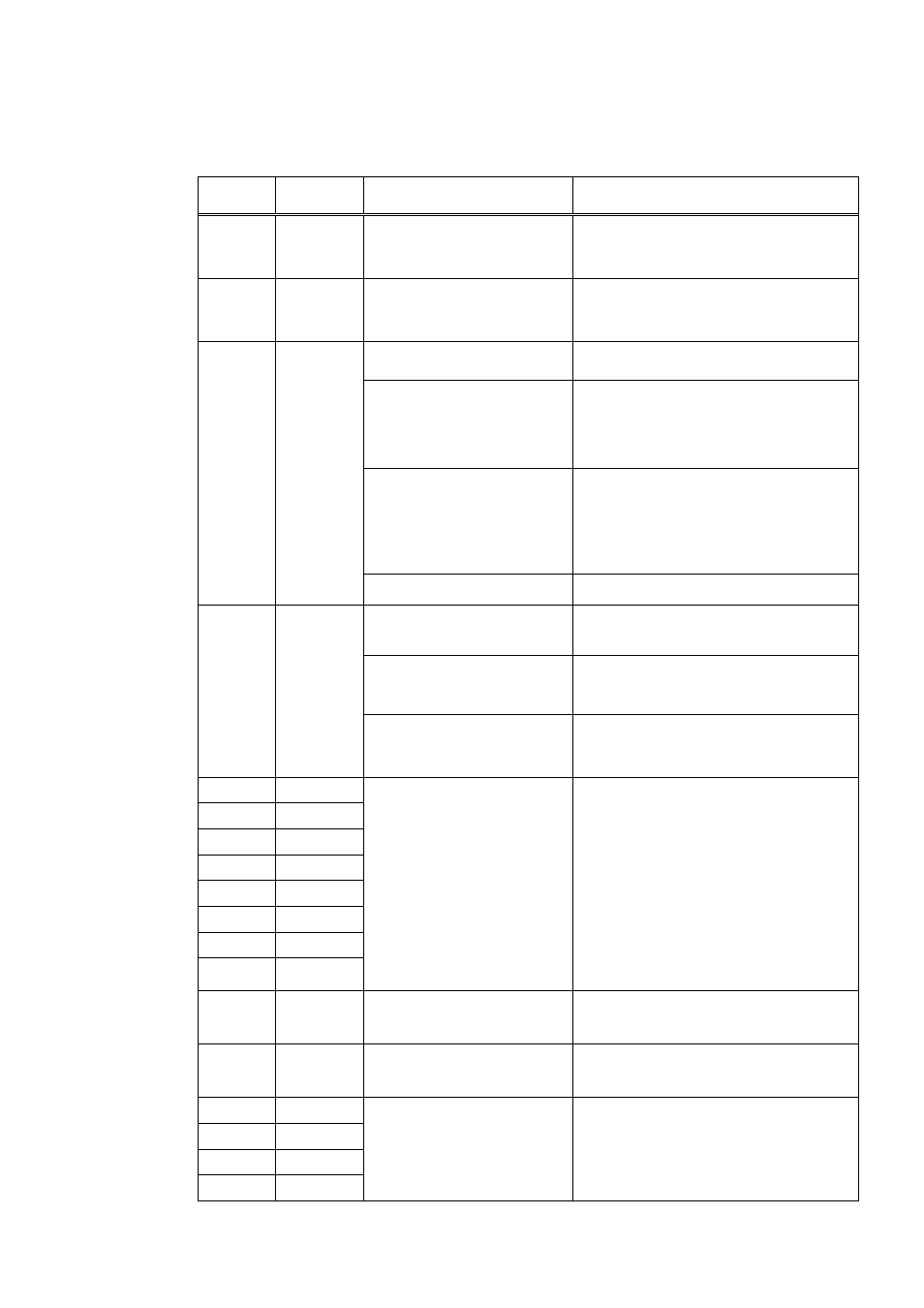

Error

number

Error code

Cause

Remedy

110

H10

Heatsink temperature detection

sensor is indicating undefined values,

an internal temperature element might

be faulty.

You need to contact Lenze (Service Hotline: (+49)

5154 82-1111).

Reset only possible by means of mains switching if

error cannot be reset: Replace or submit the

controller for repair.

111

H11

In-drive temperature detection sensor

is indicating undefined values, an

internal temperature element might be

faulty.

You need to contact Lenze (Service Hotline: (+49)

5154 82-1111).

Reset only possible by means of mains switching if

error cannot be reset: Replace or submit the

controller for repair.

Drive mechanical overload (e.g. active

load on hoists too great)

Check drive dimensioning.

Check mechanics for jamming or blockages.

Increase ramp times to reduce dynamics.

Torque limit reached

Increase torque limit:

-

Directly via MCTRL_nHiMLim_a,

MCTRL_nLoMLim_a

system variables

-

Indirectly via current limit in code C0022/000

-

Check the motor data (codes C0081/000 to

C0092/000).

Error in speed feedback system

Check speed feedback:

−

Check the parameter setting of the speed

feedback system (C0025/000, C0495/000).

−

Check the rotor position and readjust if

necessary (C0058/000, C0095/000).

−

Check the wiring/polarity of the speed feedback

system.

190

NErr

Tolerance window C0576/000 set too

low

Increase the size of the tolerance window by

adjusting the value in code C0576/000.

Active load (e.g. on hoists) too great

Check the current limit in code C0022/000 and

increase it if possible (CAUTION: Take the motor

current limit into account!).

Check drive dimensioning.

Torque limit reached

Increase torque limit:

-

Directly via MCTRL_nHiMLim_a,

MCTRL_nLoMLim_a

system variables

-

Indirectly via current limit in code C0022/000

200

NMAX

Speed feedback: Actual speed/rotor

position calculated incorrectly

Check feedback system selection (code C0025/000).

Check the motor data (codes C0081/000 to

C0092/000).

Check the rotor position and readjust if necessary

(C0058/000, C0095/000).

201

Overrun Task1

Id2

202

Overrun Task2

Id3

203

Overrun Task3

Id4

204

Overrun Task4

Id5

205

Overrun Task5

Id6

206

Overrun Task6

Id7

207

Overrun Task7

Id8

208

Overrun Task8

Id9

The runtime of the corresponding

task is longer than defined in the

watchdog time (as programmed in the

task configuration in DDS).

Reduce the task load by moving non-time-critical

program sections to lower-priority tasks, tasks with

longer interval times or the cyclic task.

Increase the task's interval time.

Check for a division by 0 in arithmetic operations.

Check your program code for infinite loops

(REPEAT/UNTIL, WHILE, FOR loops) and recursive

calls and remove them.

If you are using free CAN objects: Reduce the

number of telegrams received per time with

identifiers which do not correspond to system

blocks CAN1, CAN2 or CAN3.

If data consistency has been activated: Deactivate

the default setting for data consistency in DDS

(target system menu item) and use the

Lenze32BitTransferDrv.lib

library.

209

Float error

Sys-Task Id0

An error has occurred during a

floating point operation in the system

task.

You need to contact Lenze (Service Hotline: (+49)

5154 82-1111).

210

Float error

PLC_PRG Id1

An error has occurred during a

floating point operation in the cyclic

task (PLC_PRG or a called POU).

Check all floating point operations in the cyclic task

and subroutines called by it.

Remove/prevent divisions by 0.

211

Float error

Task1 Id2

212

Float error

Task2 Id3

213

Float error

Task3 Id4

214

Float error

Task4 Id5

An error has occurred during a

floating point operation in the cyclic

task (PLC_PRG or a called POU).

Check all floating point operations in the cyclic task

and subroutines called by it.

Remove/prevent divisions by 0.