2 prepared solution codes, 1 table of application codes, Prepared solution codes -39 – Lenze EVS93xx CrossCutter User Manual

Page 207: Table of application codes -39, Cross cutter, Appendix

Cross Cutter

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

6-39

6.2 Prepared

solution

codes

6.2.1

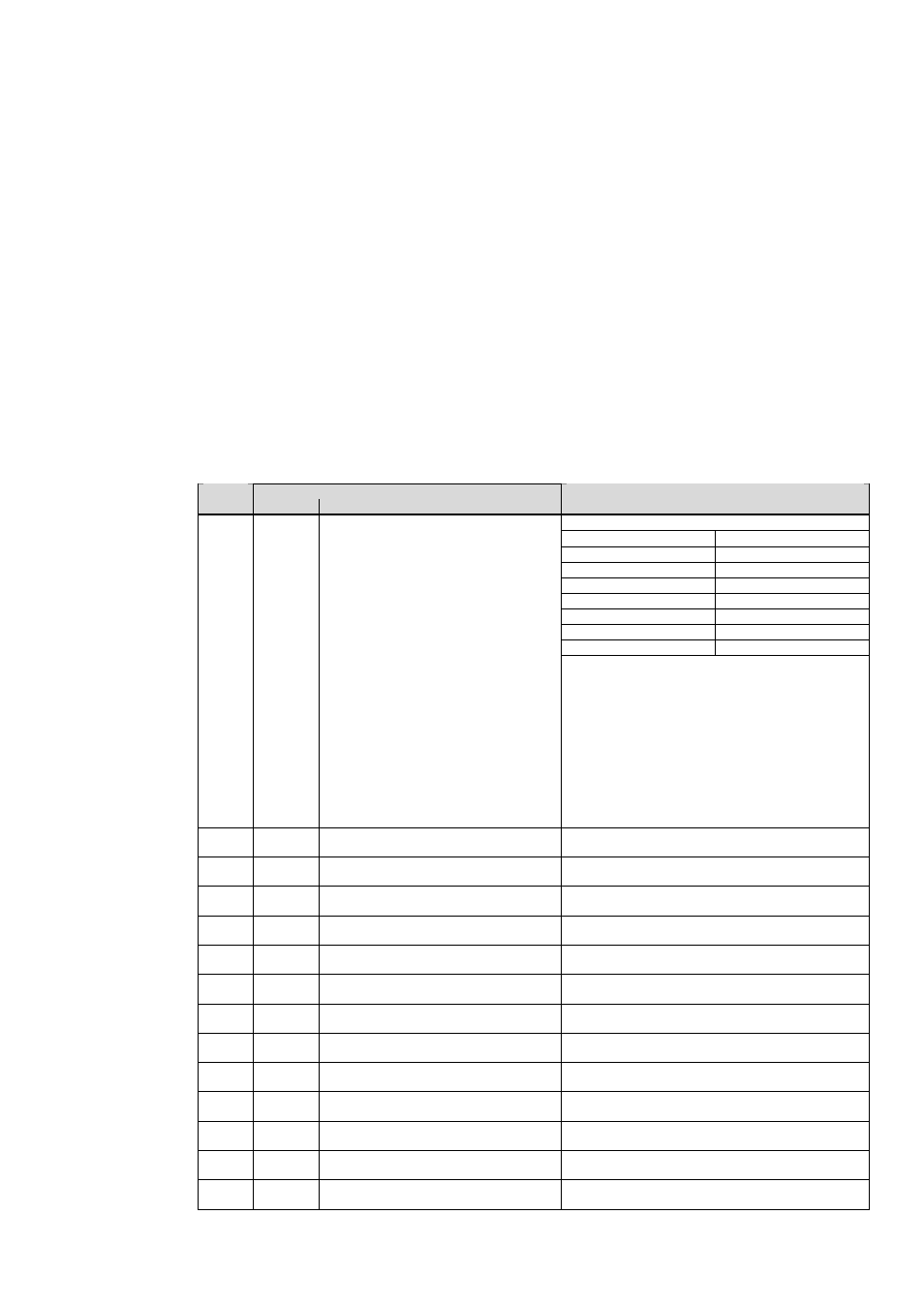

Table of application codes

In addition to the system codes (see 9300ET ServoPLC documentation) in the prepared

solution, the settings that are important for the function of the machine can be made using

application codes starting at C3000/000.

Possible settings:

Code

Default

Selection

Comment

Homing mode

0 >_Rn_MP

1 <_Rn_MP

4 >_Rp_<_Rn_MP

5 <_Rp_>_Rn_MP

6 >_Rn_>_TP

7 <_Rn_<_TP

8 >_TP

9 <_TP

C3010/

000

0

0 {1} 9

Symbols for code C3010:

> Movement in positive direction

< Movement in negative direction

Rp Positive edge of homing switch

Rn Negative edge of homing switch

TP Touch-probe edge of input I4 for 9300 Servo PLC and I2 for

ECS

MP Zero pulse edge of motor

(one per motor revolution)

The execution of the last action in each case will set the home

position (e.g. the zero pulse in the case of "MP") even if the drive

continues to move subsequently.

C3303/

000

- -

-

- Display code: Master gearbox numerator

C3304/

000

- -

-

- Display code: Master gearbox denominator

C3305/

000

- -

-

- Display code: Master feed constant

C3306/

000

- -

-

- Display code: Slave gearbox numerator

C3307/

000

- -

-

- Display code: Slave gearbox denominator

C3308/

000

- -

-

- Display code: Slave feed constant

C3350/

000

- -

{1[m_units]}

- Display code: Master angle setpoint

C3351/

000

- -

{1[m_units]}

- Display code: Current master angle

C3355/

000

- -

{1[s_units]}

- Display code: Current position

C3356/

000

- -

{1[s_units]}

- Display code: Profile set position

C3357/

000

- -

{1[s_units]}

- Display code: Auxiliary integrator

C3359/

000

- -

{1[s_units]}

- Display code: Following error

C3360/

000

- -

{1[incr.]}

- Display code: Master angle setpoint