Cross cutter, Appendix – Lenze EVS93xx CrossCutter User Manual

Page 270

Cross Cutter

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

6-102

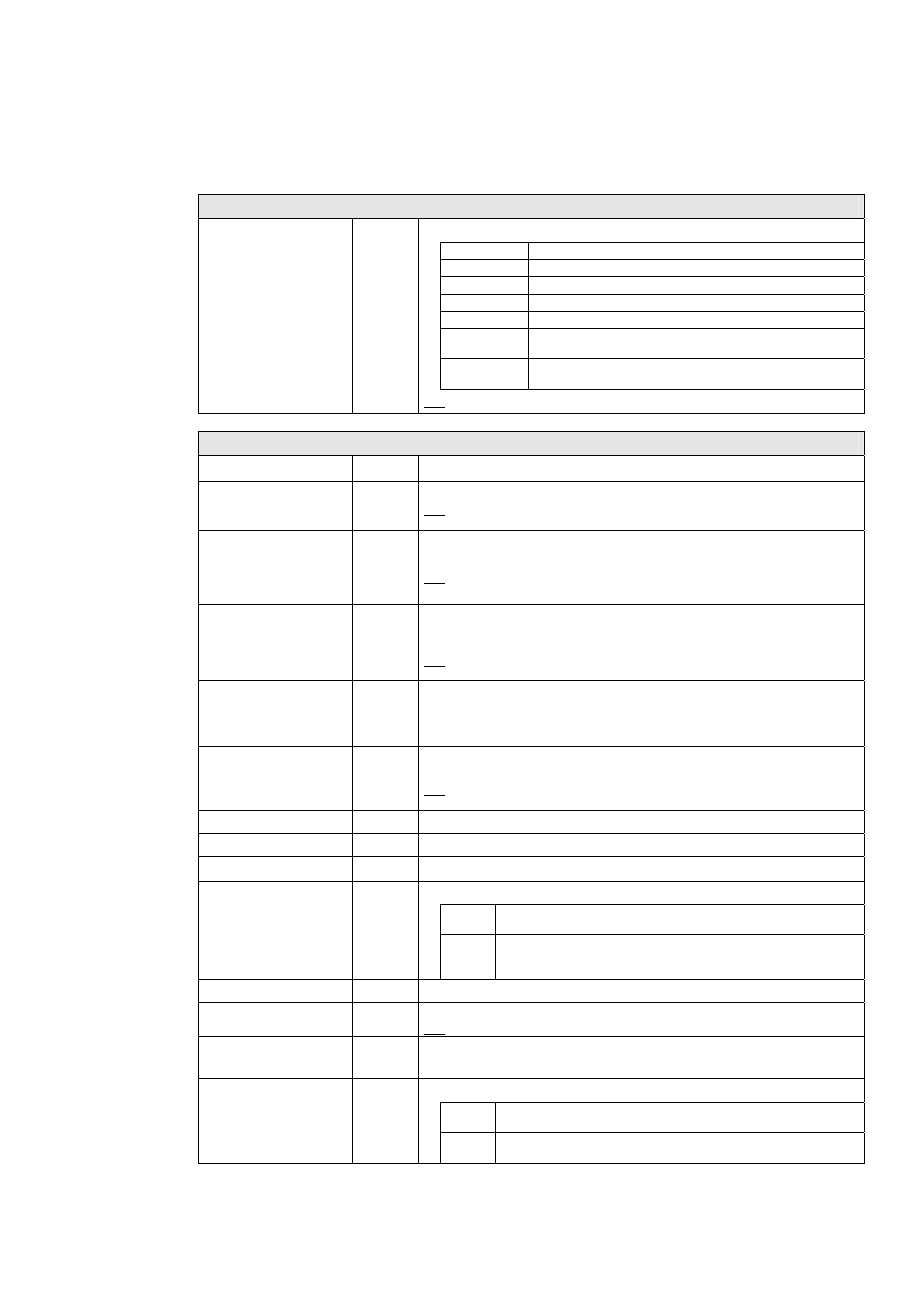

Inputs

(Variable type: VAR_INPUT)

Axis data for the master and cross-cutter axis (profile axis):

wXGearNum

Gearbox ratio master value (numerator)

wXGearDenom

Gearbox ratio master value (denominator)

dwXFeedConst

Feed constant of master drive

wYGearNum

Gearbox ratio cross-cutter axis (numerator)

wYGearDenom

Gearbox ratio cross-cutter axis (denominator)

dwYFeedConst

Feed constant of cross-cutter axis (must always be set to 3600000 =

360.0000[s_units])

wXCycles

Master speed in [incr./ms] at which the cross-cutter drive will reach its rated

number of cycles

CamAxis CAM_AXIS_

REF

Note: When using the prepared solution you can link global variable structure g_CamAxis to this input.

Outputs

(Variable type: VAR_OUTPUT)

Name Data

type

Meaning

wActCamProfileNo

WORD

Number of the last motion profile changed

Note: The state of this output variable only changes when a new calculation sequence is started via a

positive signal edge at input signal bExecute.

dnActCuttingLength

DINT

Cutting length x

cut

used to calculate the motion profile with number wActCamProfileNo (display in

0.0001[m_units]).

Note: The state of this output variable only changes when a new calculation sequence is started via a

positive signal edge at input signal bExecute.

dnCuttingLengthLimit

DINT

Maximum cutting length in 0.0001[m_units] possible when the cross cutter is in continuous duty.

Selecting a longer cutting length will lead to a motion profile with a break in the asynchronous motion

phase.

Note: The value of this output signal is only recalculated during a calculation sequence (bBusy =

TRUE).

dnXAsynchronousLength DINT Material

length

in 0.0001[m_units] to which the cross cutter is set in the asynchronous motion phase.

The value is the difference between the cutting length x

cut

and the synchronous x length

x

sync

.

Note: The value of this output signal is only recalculated during a calculation sequence (bBusy =

TRUE).

dnTotalYFeedAngle DINT

Y

final value of the motion profile selected via wActCamProfileNo in 0.0001[s_units]. The value is

taken from the y final value of the basic cam defined in CamDesigner.

Note: The value of this output signal is only recalculated during a calculation sequence (bBusy =

TRUE).

dnX1 DINT

Starting point of the pause in 0.0001[m_units] only if bStartStopOperation = TRUE.

dnX2 DINT

Finishing point of the pause in 0.0001[m_units] only if bStartStopOperation = TRUE.

dnYAsynch

DINT

Y position in 0.0001[s_units] at which the cross-cutter knife drum will be in the initial position.

Status signal: Newly calculated cam induces start/stop operation of cross cutter.

FALSE The selected cutting length (dnActCuttingLength) is less than the limit cutting length

for start/stop operation (dnCuttingLengthLimit).

bStartStopOperation BOOL

TRUE The selected cutting length (dnActCuttingLength) is greater than the limit cutting

length for start/stop operation (dnCuttingLengthLimit) => The length of the pause will

be extended accordingly in the asynchronous motion phase.

nMaxMasterVelocity_v INT

Maximum possible line speed for the set cutting length in [incr./ms].

wTotalNumberOfPoints WORD

Number of interpolation points in the motion profile selected via wActCamProfileNo

Note: The value of this output signal is only reset during a calculation sequence (bBusy = TRUE).

wActNumberOfPoint WORD

Newly calculated interpolation point in the motion profile selected via wActCamProfileNo: This output

can, for example, be used as a progress indicator. The value range is 0 … (wTotalNumberOfPoints -

1).

The calculation sequence for the new cross-cutter motion profile is in progress.

FALSE The calculation sequence for the new cross-cutter motion profile has been

completed successfully (bDone = TRUE) or aborted (nState < 0).

bBusy BOOL

TRUE The calculation sequence for the cross-cutter motion profile (wActCamProfileNo) is

in progress.