Cross cutter, Features of the "cross cutter" prepared solution – Lenze EVS93xx CrossCutter User Manual

Page 76

Cross Cutter

Features of the "Cross Cutter" prepared solution

Prepared Solution Servo PLC / ECSxA 1.1 EN

2-62

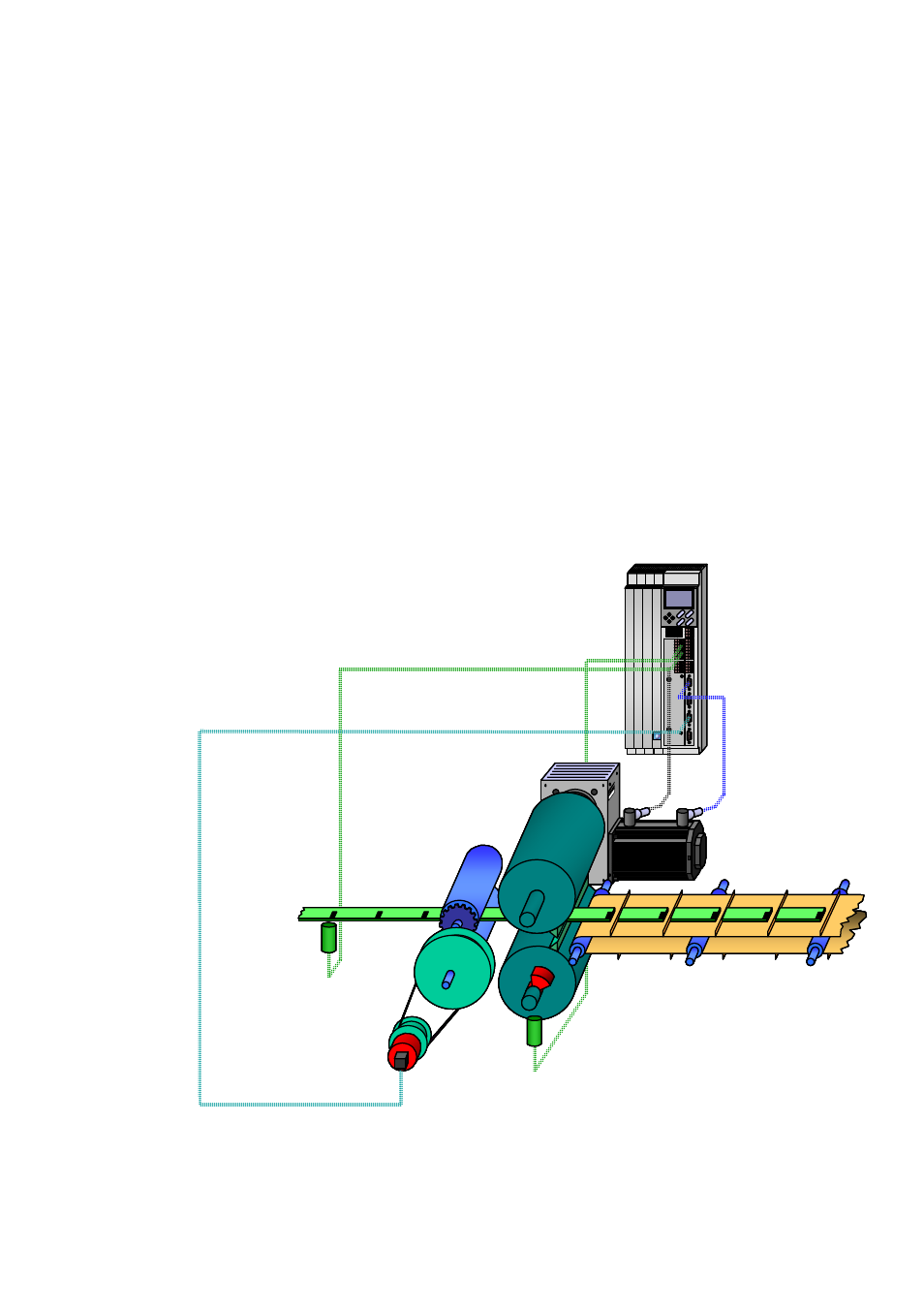

Mark-controlled operation:

In mark-controlled operation, mark control is implemented in addition to length control. Mark

control compensates inaccuracies via touch-probe correction. This ensures that positions are

corrected accordingly during operation. High-speed hardware signals ("touch probe") which

determine the deviation between the set and actual position on an interrupt-specific basis in the

ServoPLC are used for this purpose. An example application of mark control is illustrated in

Figure 21. In this application, mark control is used to cut a defined length from the material

being processed using print marks. In an application of this type, the length to be cut is sent to

the system and the length calculation function converts this value into an appropriate motion

profile. The print marks on the material to be processed are then used to correct the length

calculation. As soon as the touch-probe sensor detects a print mark, it compares the position

set accordingly with the actual position. In accordance with the deviation a signal is then

generated with a positive or negative sign to compensate the prevailing path difference. Mark

control can be used equally for the synchronous and asynchronous cross cutter. Mark

correction is only activated in Continuous cutting mode.

L

L

L

Figure 21: Mark-controlled operation of a cross-cutter application