Cross cutter, Appendix – Lenze EVS93xx CrossCutter User Manual

Page 256

Cross Cutter

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

6-88

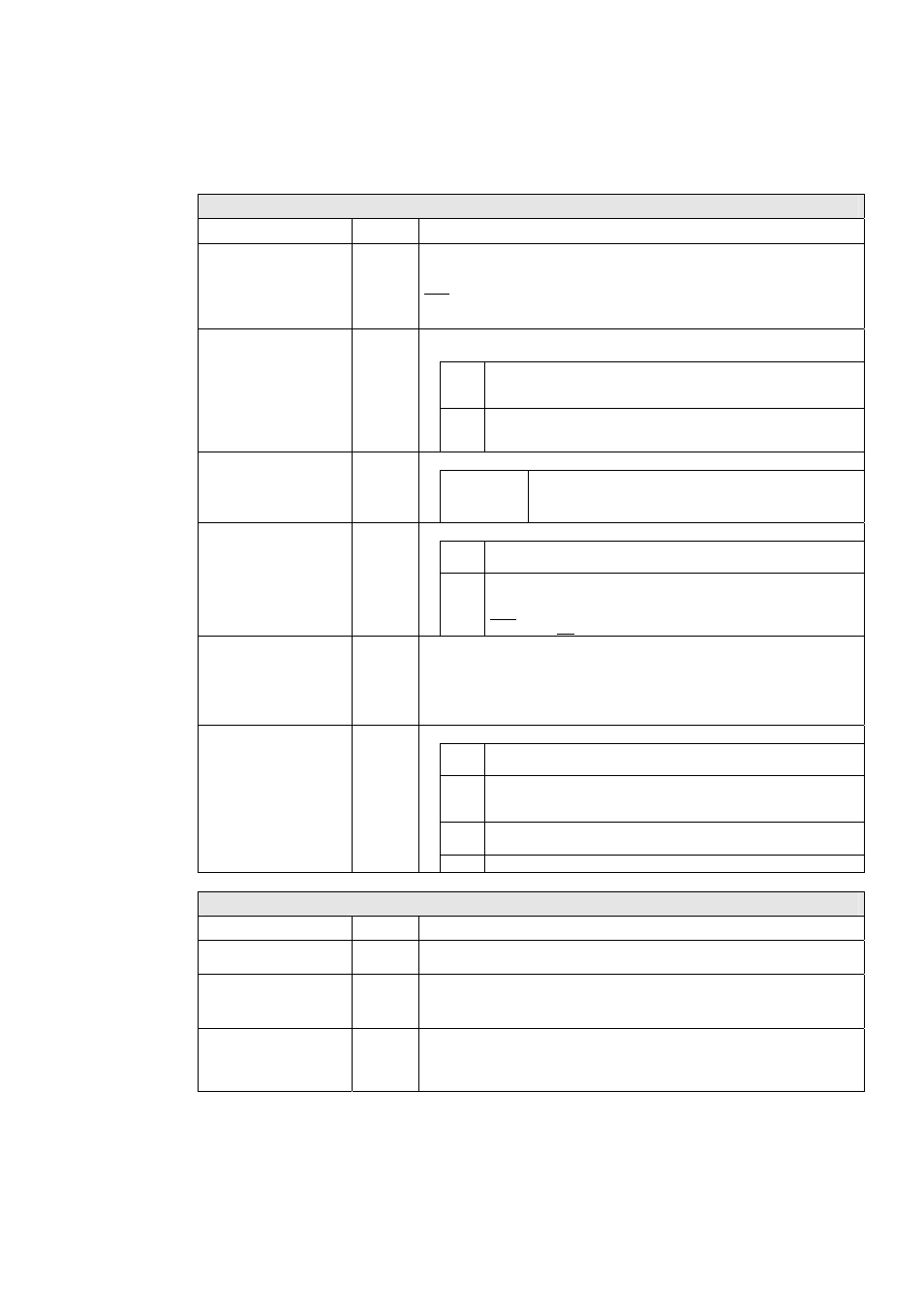

Outputs

(Variable type: VAR_OUTPUT)

Name Data

type

Value/Meaning

bTpReceivedOut_b

BOOL

Display of a valid print-mark pulse (print-mark pulse inside the tolerance window): A FALSE-

TRUE edge indicates a valid print-mark signal.

Note: The associated last-scan value for a valid print mark corresponds to the value at input

dnActIncLastScan_p. This makes it possible to evaluate the print-mark signal on a touch-probe-

specific basis.

Indicates whether a tolerance window has been defined by an initial print-mark pulse at input

bTpReceivedIn_b:

FALSE The tolerance window has not yet been defined (the position of the tolerance

window will be defined by the first print-mark pulse detected at input

bTpReceivedIn_b).

bTpWindowActive_b BOOL

TRUE The position of the tolerance window is known – all subsequent print-mark pulses

are checked in respect of their position inside the tolerance window and output to

bTpReceivedOut_b if applicable.

Display bit for error pulses:

bNoTpInWindowDetected_b BOOL

FALSE

=>

TRUE

No print-mark pulses have been detected in the tolerance window. The

state of the output will not change until the tolerance window opens

again.

Display bit for the open tolerance window:

FALSE The tolerance window is closed: A print-mark pulse at input bTpReceivedIn_b will

be blocked and not output to output bTpReceivedOut_b.

bTpWindowOpen_b BOOL

TRUE The tolerance window is open: A print-mark pulse at input bTpReceivedIn_b will

be output to output bTpReceivedOut_b.

Note: The output will be TRUE for at least one cycle, even if the tolerance

window opens and closes again within a task cycle.

dnTpDistance_p

DINT

Distance between two valid print-mark pulses in [incr.]:

This output can be used for control and monitoring, e.g. in order to:

• Identify inaccuracies or diffusions affecting the application of print marks.

• Set the print-mark distance as a reference value for the setpoint distance (input signal

dnCycleLength_p).

Status of the Tp_Window function block:

2

The first print mark is expected at input bTpReceivedIn_b to define the position of

the tolerance window.

0

Normal operation: Incoming print-mark pulses at input bTpReceivedIn_b are

checked in respect of their position inside the tolerance window and output to

output bTpReceivedOut_b if applicable.

-2

The width of the tolerance window (input dnTpWindowSize_p) is outside the

permitted range 2 … (dnCycleLength_p – 1).

nStatus INT

-4

The function block is reset by input bReset_b = TRUE.

Internal

(Variable type: VAR)

Name Data

type

Meaning

dnTpPosition_p

DINT

Position of the tolerance window: The variable indicates the centre of the tolerance window in

the cycle. The value is calculated by dividing dnCycleLength_p by 2.

dnLowerWindowLimit_p

dnUpperWindowLimit_p

DINT

Upper/lower limit of the tolerance window: The variables are calculated as follows:

dnLowerWindowLimit_p =

dnTpPosition_p - dnTpWindowSize_p/2

dnUpperWindowLimit_p

= dnTpPosition_p + dnTpWindowSize_p/2.

dnOut_p

DINT

Control variable: This position value is derived by integrating the speed input nIn_v and runs in

the value range 0 … (dnCycleLength_p – 1), thereby mapping a cycle (setpoint distance

between two valid print marks). It combines with the dnLowerWindowLimit_p and

dnUpperWindowLimit_p variables to generate the bTpWindowOpen_b output variable.