Cross cutter, Appendix – Lenze EVS93xx CrossCutter User Manual

Page 259

Cross Cutter

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

6-91

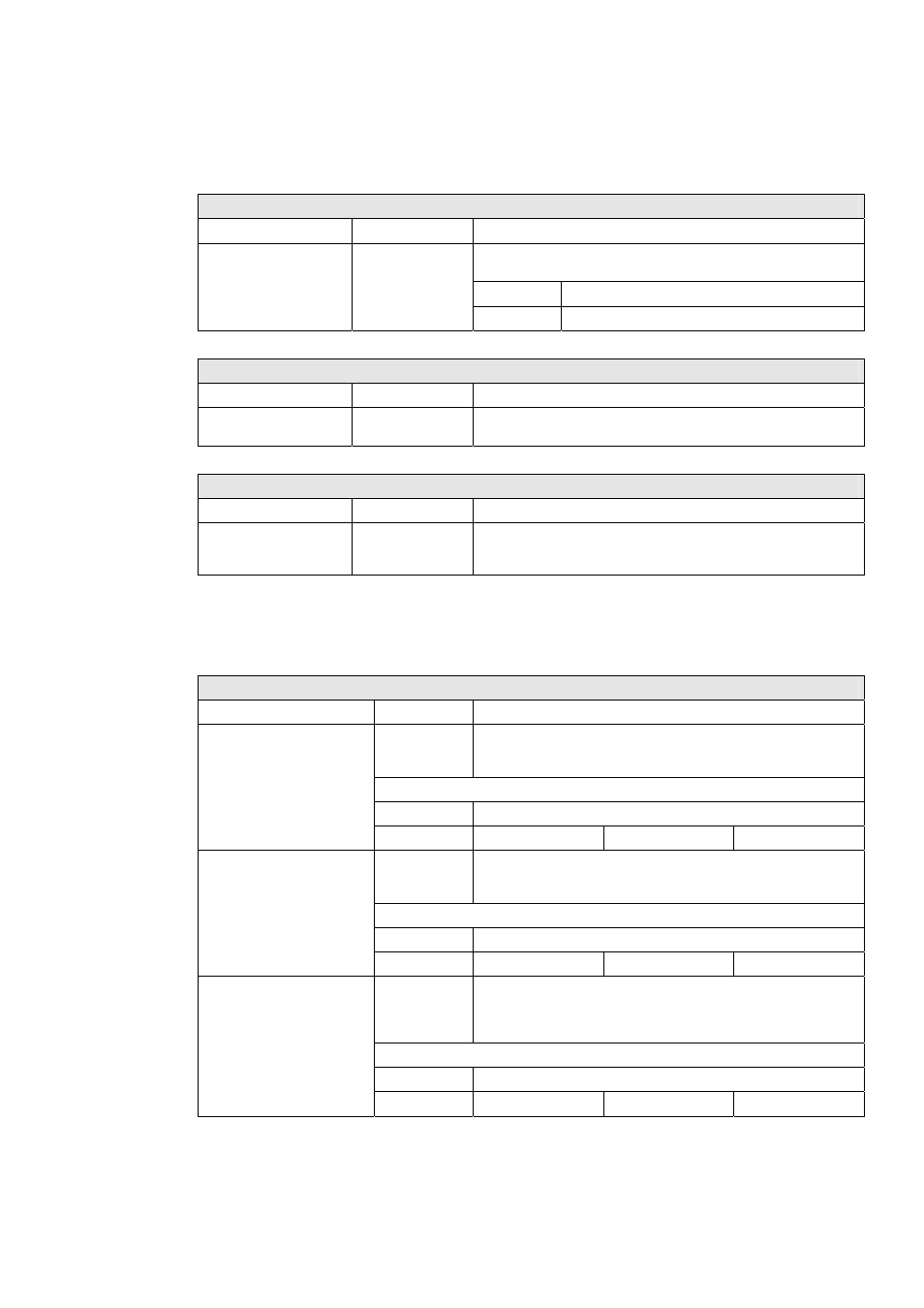

Inputs

(Variable type: VAR_INPUT)

Name Data

type

Value/Meaning

Indicates that the cross cutter knife is not in Material. Connect this value to variable

g_bKnifeNotInMaterial.

TRUE

The cross cutter knife is not in material.

bKnifeNotInMaterial BOOL

FALSE

The cross cutter knife is in material.

Outputs

(Variable type: VAR_OUTPUT)

Name Data

type

Value/Meaning

nxVelTrimmingFactorOut_v

INT

Speed signal which can be used to perform manual x trimming. This value must be

added to the master speed of the x axis.

Inputs/Outputs

(Variable type: VAR_IN_OUT)

Name Data

type

Value/Meaning

dnOutTpPos_p DINT Position signal used for manual x trimming. Connect this value to variable

dnTpPos_p of the L_CamSetXAxisVelocity function block.

Note: Assign a retain variable to this input/output!

In order to be able to use the full functionality of the XPositionTrimming function block, you need

to create 7 codes.

The specific variables used for this purpose are:

Variable

Value/Meaning

Name Data

type

Value/Meaning

DINT

Variable for acceleration time when using bTrimPosDirection and

bTrimNegDirection. The acceleration and deceleration times relate to a change in

the output value from 0 to 100% (100% = 16384).

Possible settings

Default

Selection

xxx.L_RFG1.dnTir

0.000 s

0.000

{0.001 s}

999.999

DINT

Variable for deceleration time when using bTrimPosDirection and

bTrimNegDirection. The acceleration and deceleration times relate to a change in

the output value from 0 to 100% (100% = 16384).

Possible settings

Default

Selection

xxx.L_RFG1.dnTif

0.000 s

0.000

{0.001 s}

999.999

ARRAY OF DINT

Variable for deceleration ramp to stop before reaching the set position

(

bExecuteSetPositionTrimming = FALSE) when using variables

dnSetPositionTrimming_p and bExecuteSetPositionTrimming.

The ramp assumes 4000 rpm.

Possible settings

Default

Selection

xxx.L_CamPosCtrlLin1.adnTiPos[1]

1.000 s

0.010

{0.001 s}

130.000