Cross cutter – Lenze EVS93xx CrossCutter User Manual

Page 125

Cross Cutter

Installing and starting up the "CrossCutter" prepared solution

Prepared Solution Servo PLC / ECSxA 1.1 EN

3-111

Points:

Entry indicating the number of interpolation points for the

motion and torque precontrol profiles. The number of

interpolation points should be selected so that the x

position of the setpoint-generating task moves forward

one point per task cycle. An approximate calculation of the

number of interpolation points can be arrived at as follows:

task

MC

cycle

s

po

t

n

min

points

n

_

int

1

1

]

[

]

[

6000

⋅

⋅

=

where

n

points

:

Number of interpolation points to be selected

per motion

profile

n

cycle

:

Maximum number of cycles per minute

t

MC_task

: Interval time of setpoint-generating task

Example: The setpoint-generating task is processed in the

2 ms cycle. At a maximum clock-pulse rate of 60

cuts/minute a sensible value for the number of

interpolation points would be

]

[

500

]

[

2

1

]

[

60

1

]

[

]

[

6000

int

points

ms

/min

cuts

min

points

n

s

po

=

⋅

⋅

=

Tip:

Practical Tests have shown, that a number of points from 50 up to 100 are normaly enough

in most applications and the calculationtime will be smaller.

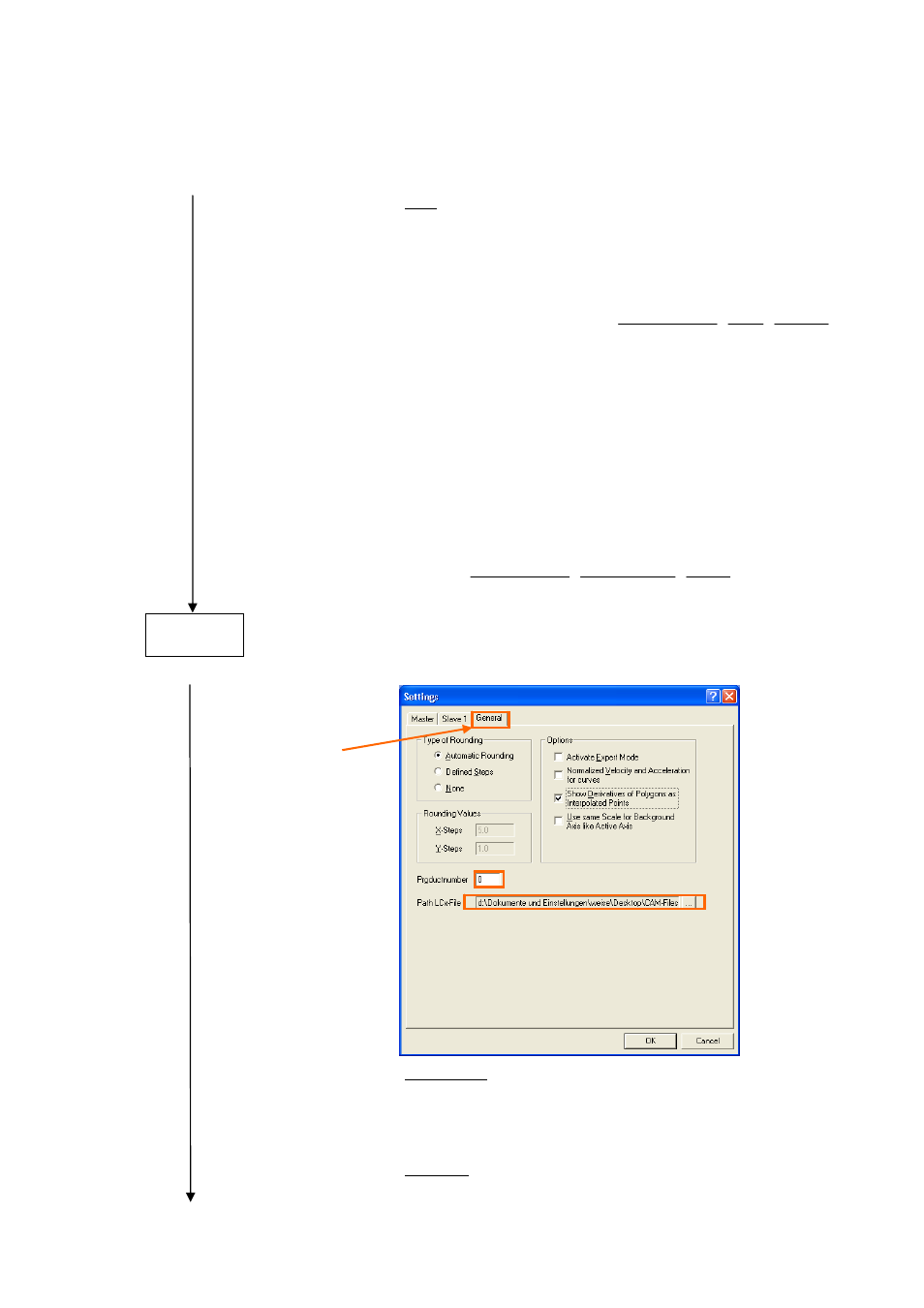

Click the General tab to specify the profile number to be processed for the motion profile of the cross cutter

and define a directory path for the LC9 file:

Product number:

You will need to enter a profile number (product number)

here in order to enable the motion profile to be addressed

subsequently on the ServoPLC/in the ECS servo system.

Example: The default setting for the first motion profile for

the cross- cutter application is profile number 0.

LCx file path:

Entry indicating the directory path (memory location) for

the LC9 file to be generated

Click

Ok to go back to the main CamDesigner window.

Step 5