Cross cutter, Features of the "cross cutter" prepared solution – Lenze EVS93xx CrossCutter User Manual

Page 80

Cross Cutter

Features of the "Cross Cutter" prepared solution

Prepared Solution Servo PLC / ECSxA 1.1 EN

2-66

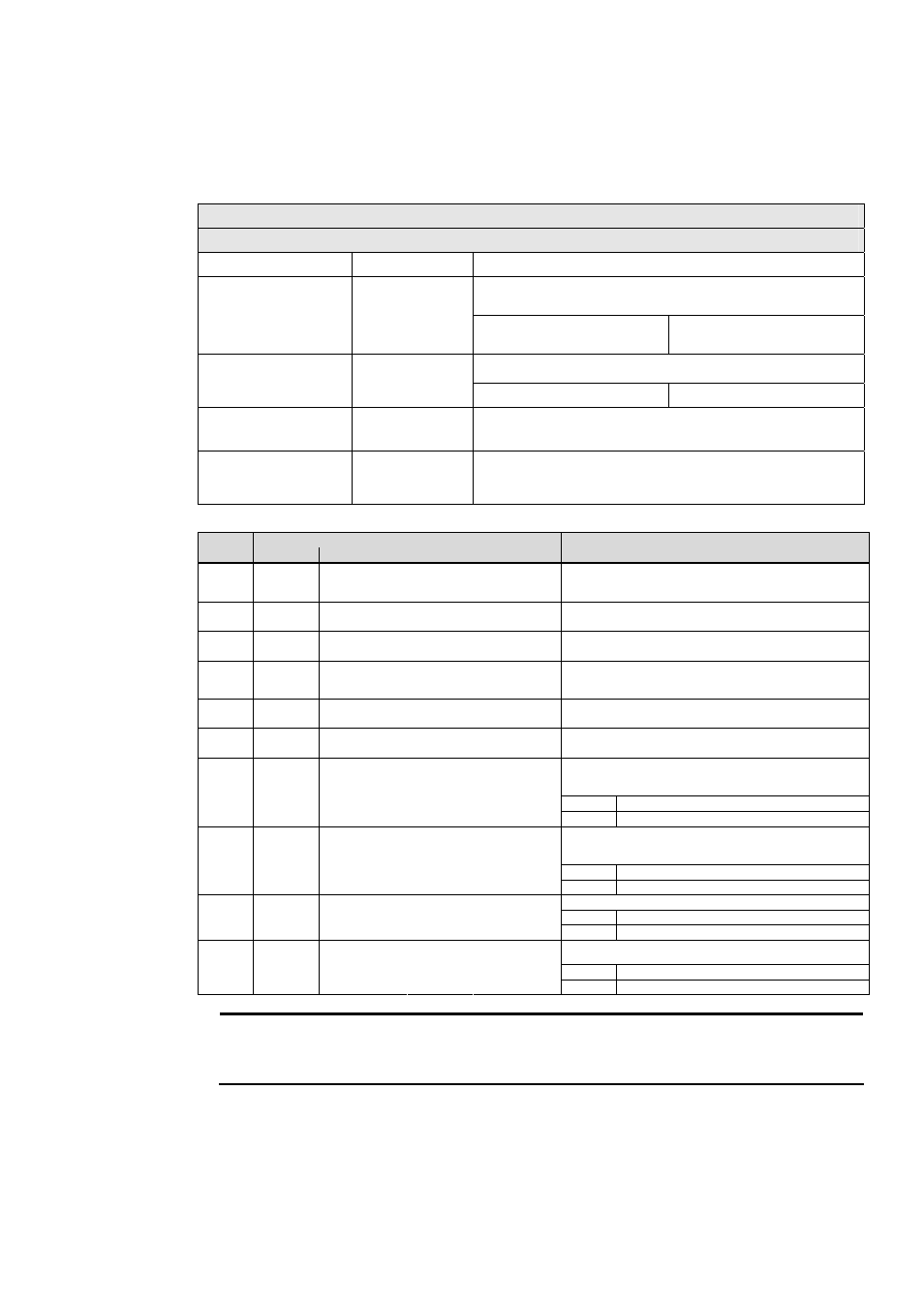

Outputs

Global variables

(Variable type: VAR_GLOBAL)

Name Data

type

Value/Meaning

"Mark correction in progress" status signal

This value is displayed in code C4150/000 bit 7.

g_bXTpSyncBusy BOOL

TRUE = Mark correction active,

correcting position difference.

FALSE = Mark correction not active at

this time.

"Knife not in material" status signal

This value is displayed in code C4150/000 bit 29.

g_bKniveNotInMaterial BOOL

TRUE = Knife is not in material.

FALSE = Knife is in material.

g_dnXDifference_p DINT

Correction value of mark correction

This value is only valid if mark correction with a ramp generator has been selected

(C4135/000 Bit 22 = TRUE, or g_bRfgXTpEnable = TRUE ).

g_dnXTpDifference_p DINT

Difference between two print-mark signals

This value is only valid if mark correction with a ramp generator has been selected

(C4135/000 Bit 22 = TRUE, or g_bRfgXTpEnable = TRUE ).

Possible settings:

Code

Default

Selection

Comment

C3649/

001

0.100

0.000...

{0.01[s]}

...129.99 Abort ramp for ramp generator: Assumes a speed of 4000

rpm. Used if the knife cuts into the material whilst mark

correction is in progress.

C3649/

002

5.000 0.000...

{0.01[s]}

...129.99 Acceleration

ramp for ramp generator: Assumes a speed of

4000 rpm.

C3649/

003

5.000 0.000...

{0.01[s]}

...129.99 Deceleration

ramp for ramp generator: Assumes a speed of

4000 rpm.

C3650/

001

200

0

{1 rpm}

15000 Maximum positive correction speed for mark synchronisation

with a ramp generator and correction speed for mark

synchronisation without a ramp generator.

C3650/

002

200

{1 rpm}

15000 Maximum negative correction speed for mark synchronisation

with a ramp generator.

C3668/

000

370.0000 0.0000

{1.0000

m_units}

214000.0000 Distance measured from mark sensor to 6 o'clock position of

knife.

Application control word bit 21: Activate print-mark

synchronisation.

TRUE

Print-mark synchronisation activated.

C4135/

000

Bit 21

0

0 {1} 1

FALSE

Print-mark synchronisation deactivated.

Application control word bit 22: Activate ramp generator for print-

mark synchronisation.

TRUE

Ramp generator activated.

C4135/

000

Bit 22

0

0 {1} 1

FALSE

Ramp generator deactivated.

Application status word bit 7: Mark correction active.

TRUE

Mark correction active.

C4150/

000

Bit 7

-

- - -

FALSE

Mark correction not active.

Application status word bit 29: Knife is in material.

TRUE

Knife in material.

C4150/

000

Bit 29

-

- - -

FALSE

Knife not in material.

Note!

Digital input I5 on the Servo PLC or I1 on the ECS is permanently assigned to the print-

mark-sensor signal. The user needs to assign the print-mark-sensor signal to this input!