Cross cutter, Appendix – Lenze EVS93xx CrossCutter User Manual

Page 230

Cross Cutter

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

6-62

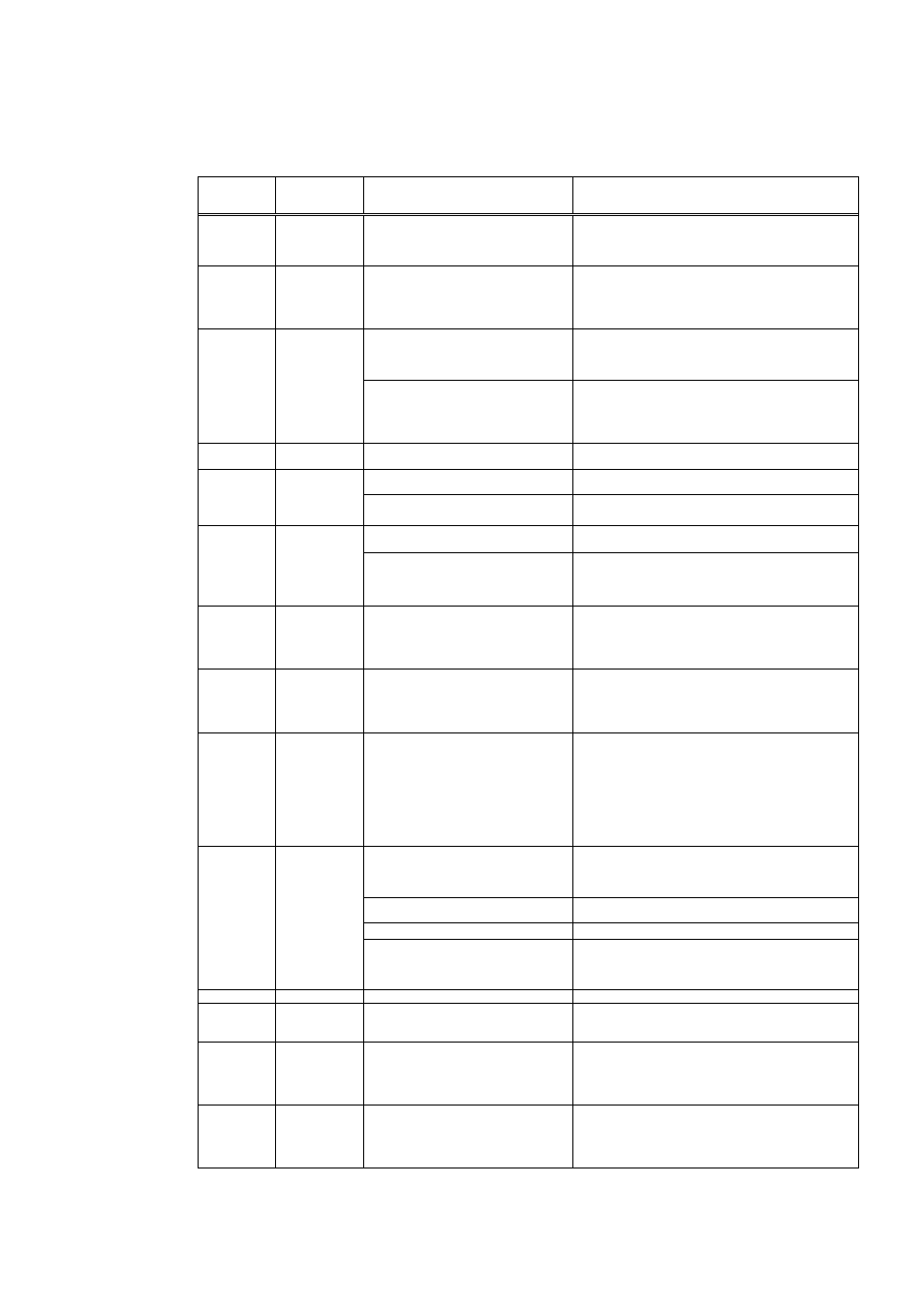

Error

number

Error code

Cause

Remedy

74

PEr

Error in internal program flow

Read out the parameter set and send it to Lenze for

further analysis along with the source project

(contact Lenze first by calling the Service Hotline:

(+49) 5154 82-1111).

75

Pr0

Invalid data in EEPROM when loading

parameters from EEPROM to main

memory

CAUTION: The default setting is

loaded automatically!

Set the required parameters and save them to non-

volatile EEPROM via code C0003/000, then perform

mains switching/disconnection of the control

voltage.

Error during internal transmission of

parameters from EEPROM to main

memory

Read out the parameter set and send it to Lenze for

further analysis along with the source project

(contact Lenze first by calling the Service Hotline:

(+49) 5154 82-1111).

79

PI

Use of a parameter set which does

not match the device (9300EI/ET) in

the GDC software/in GDLoader

Use the parameter set matching the controller in the

GDC software/in GDLoader, send it to the controller

again and save it to non-volatile memory in the

controller via C0003/000. Finally, perform mains

switching/disconnection of the control voltage.

80

PR6

Too many user codes created

Check and reduce the number of user codes you

have created.

Resolver cable partially or entirely

interrupted/disconnected

Check the resolver cable for open circuits.

Check the resolver.

82

Sd2

Resolver not in use/not connected Deactivate

monitoring

by setting code C0586/000 = 3

if you are not using a resolver.

Encoder cable break

Disconnect the cable from X9 and check for open

circuits.

83

Sd3

Pin 8 at input X9 not assigned

Assign +5 V DC to pin 8 at input X9.

OR:

Deactivate monitoring by setting code C0587/000 = 3.

85

Sd5

Current master value at X6 (terminals

1 and 2) less than 2 mA

Check the cable for open circuits.

Check the master current value encoder.

Check the setpoint configuration in C0034/000.

OR:

Deactivate monitoring by setting code C0598/000 = 3.

86

Sd6

Motor temperature detection encoder

at X8 is indicating undefined values.

Check cable at X8 for snug fit and open circuits.

Disconnect temperature element (PTC/KTY) and

check resistance (must not be

∞).

OR:

Deactivate monitoring by setting code C0594/000 = 3.

87

Sd7

Absolute value encoder with RS485

interface is not sending any data.

Check cable at X8 for snug fit and open circuits.

Check that the absolute value encoder is functioning

correctly.

Set voltage supply to 8.0 V via C0421/000.

No encoder with HIPERFACE interface connected

CAUTION: Once the cause of the error has been

removed, disconnect the servo controller completely

from the power supply.

The connector on the sin/cos encoder

or controller (terminal X8) has

detached itself completely (open

connection) or is loose.

Check the plug connection on the controller

(terminal X8) and on the encoder system

Error in the connecting cable to the

sin/cos encoder

Check the cable connector and conductor pin

assignment.

Encoder electronics defect

Replace a defective encoder.

88

Sd8

Note: In particular for monitoring the encoder on a

synchronous machine, set the

error response "Error" (TRIP) by setting code C0580

= 0.

89

PL

Error during rotor position adjustment Repeat rotor position adjustment.

91

EEr

One of the digital signals linked to the

DCTRL_bTripSet_b

system variable is

indicating the status TRUE.

Check the signal source at the DCTRL_bTripSet_b

system variable. The "Eer" error can be reset if this

signal source has switched to FALSE.

105

H05

You need to contact Lenze (Service Hotline: (+49)

5154 82-1111).

Reset only possible by means of mains switching if

error cannot be reset: Replace or submit the

controller for repair.

107

H07

An incorrect power section was

detected during initialisation of the

controller.

You need to contact Lenze (Service Hotline: (+49)

5154 82-1111).

Reset only possible by means of mains switching if

error cannot be reset: Replace or submit the

controller for repair.