2 application error messages, Application error messages -65, Cross cutter – Lenze EVS93xx CrossCutter User Manual

Page 233: Appendix

Cross Cutter

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

6-65

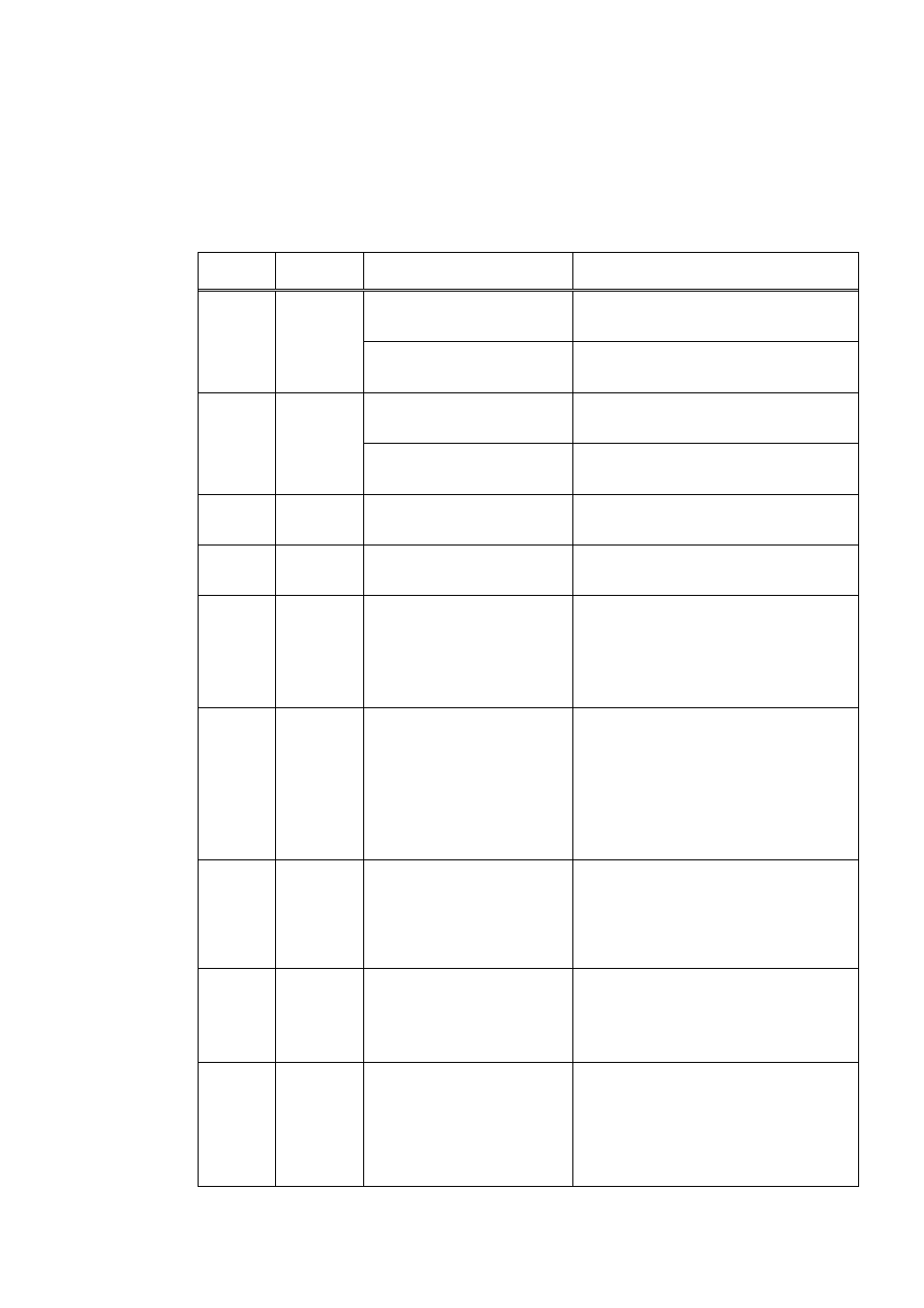

6.3.2

Application error messages

Error

number

Error code

Cause

Remedy

Positive limit switch reached

Retract the positive limit switch:

Acknowledge the error message.

Run the drive in a negative direction, e.g. via manual

jog, until the positive limit switch retracts.

400

PosLimit

Switch

Limit switch signal not connected to

terminal E2

Set the level inversion for digital input I2 to inverse

logic (C0114/002 = 1) or

Establish a permanent wire-bound connection

between terminal I2 and 24 V DC.

401

NegLimit

Switch

Negative limit switch reached

Retract the negative limit switch:

Acknowledge the error message.

Run the drive in a positive direction, e.g. via manual

jog, until the negative limit switch retracts.

Limit switch signal not connected to

terminal E1

Set the level inversion for digital input I1 to inverse

logic (C0114/001 = 1) or

Establish a permanent wire-bound connection

between terminal I1 and 24 V DC.

402

PosSWLimit

Positive software limit position

reached/overtravelled

Run the drive in a negative direction in the

permissible traversing range.

Set the limit value for the positive software limit

position (C3223/000) to a higher value.

403

NegSWLimit

Negative software limit position

reached/overtravelled

Run the drive in a positive direction in the

permissible traversing range.

Set the limit value for the negative software limit

position (C3224/000) to a lower value.

405

FollError

The drive cannot follow the setpoint,

the current following error is greater

than the value set in C3218/001.

-

Increase the current limit in C0022/000, thereby

increasing the torque (CAUTION: Be aware of

the increase in motor temperature!).

-

Reduce the dynamic requirements

(accelerations/decelerations).

-

Increase the following error limit in C3218/001.

-

You may need to check the drive dimensioning.

406

HomError

An attempt has been made to

approach an absolute position

without the measuring system zero

point being known to the drive.

-

Prior to carrying out the first positioning

operation, perform homing (manual

referencing, homing via positioning program)

and/or set the home position in the positioning

program.

-

Define the measuring system zero point for

operation with absolute value encoders.

OR:

-

Select relative positioning if relative positioning

(no absolute measuring system!) is possible.

408

UserQSP

Automatic operation has been

aborted due to a quick stop command

being sent by the user.

-

A quick stop can be triggered via the terminals,

a bus system (AIF or CAN bus) or the control

code C0135/000 (system variable

MCTRL_bQspOut_b

).

-

Reset the quick stop command, acknowledge

the error and perform a controlled reset to

return the drive to the required operating mode.

409

MaxVelConflit

The traversing speed defined in the

positioning profile is generating a

motor speed in excess of the

maximum speed C0011/000.

-

Reduce the speed value in the traversing

profile.

-

Alternatively, increase the maximum speed in

code C0011/000. Take the motor limit speed,

maximum system speeds, etc. into account

when increasing the maximum speed.

410

DriveNotRdy

Automatic operation has been

aborted due to the user setting a

controller inhibit.

-

A controller inhibit can be triggered via

terminal 28, a bus system (AIF or CAN bus),

control codes C0040/000 and C0135/000 or

system variables DCTRL_bCinh1_b and

DCTRL_bCinh2_b

.

-

Re-enable the target system, acknowledge the

error and perform a controlled reset to return

the drive to the required operating mode.