Cross cutter – Lenze EVS93xx CrossCutter User Manual

Page 124

Cross Cutter

Installing and starting up the "CrossCutter" prepared solution

Prepared Solution Servo PLC / ECSxA 1.1 EN

3-110

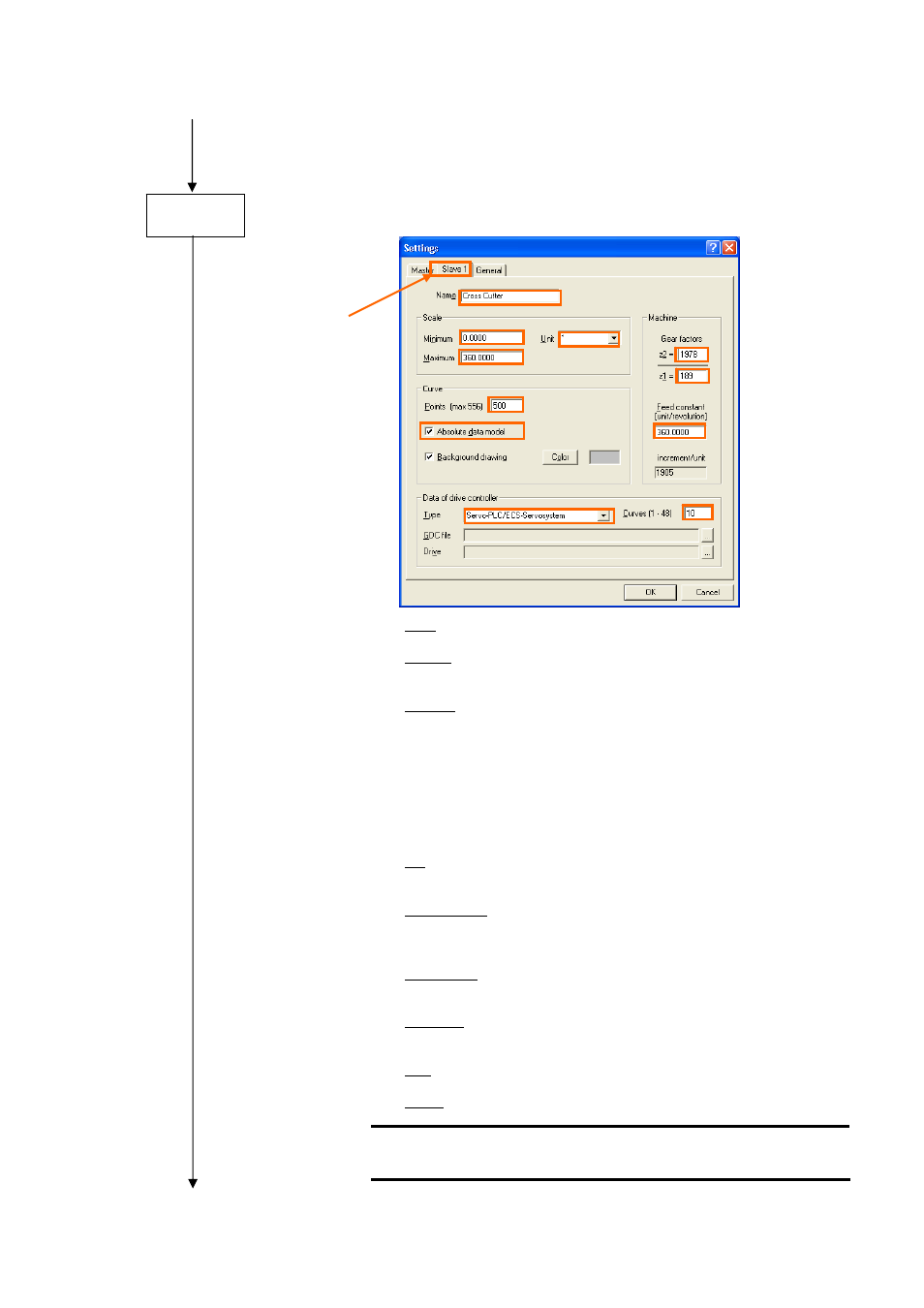

Click the Slave 1 tab to make the settings for the drive axis on the rotary cross cutter:

Name:

Name of the cam axis (in the example: "CrossCutter")

Minimum:

Minimum position in the cross-cutter cycle, must

always be set to 0.0000[°]

Maximum:

Maximum position y

max

in the cross-cutter cycle:

This value is dependent on the mechanical engineering of

theknife drum and may exhibit the following values:

y

max

= 360.0000[°]:

1 knife per knife drum

y

max

= 180.0000[°]:

2 knives per knife drum

y

max

= 120.0000[°]:

3 knives per knife drum

etc.

y

max

= 60.0000[°]:

6 knives per knife drum

Unit:

Unit in which the feed motion of thecross cutter is scaled

(in the example: 1[s_unit] = 1[°])

Gearbox factors:

Entry indicating the gearbox factors of the cross-cutter

drive (with numerator and denominator indicated

separately) (in the example: z

2

: z

1

= 1978 : 189)

Feed constant:

Entry indicating the feed constant of the cross cutter,must

always be set to 360[°]

Data model:

In order to be able to modify interpolation points in motion

profiles subsequently, you must select the absolute data

model.

Type:

Select the "ServoPLC/ECS servo system" as your target

system.

Profiles:

Selection of the number of motion profile (in the example:

10 motion profiles selected)

Caution!

The prepared solution needs 10 motion profiles!

Step 4