Cross cutter, Appendix – Lenze EVS93xx CrossCutter User Manual

Page 229

Cross Cutter

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

6-61

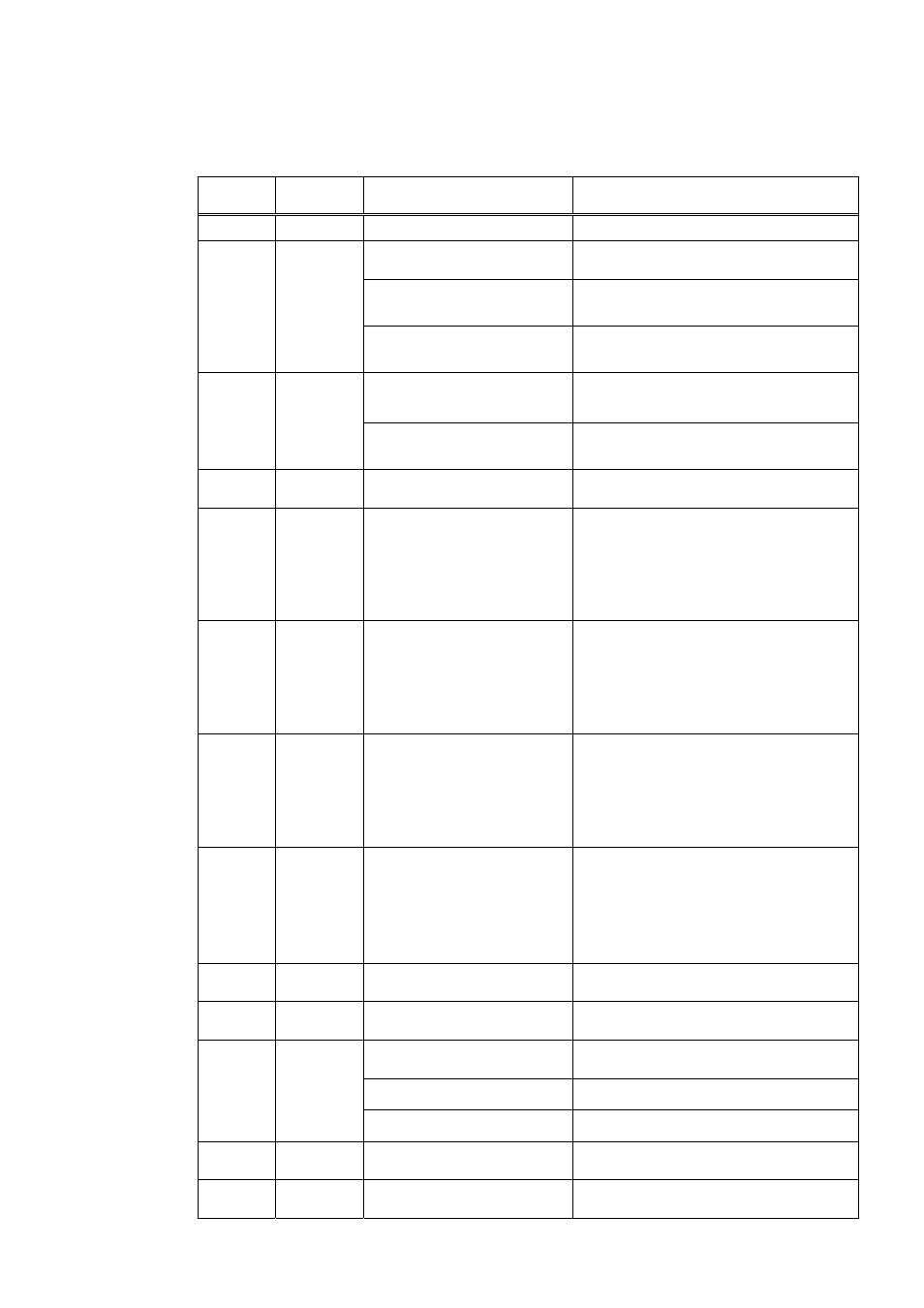

Error

number

Error code

Cause

Remedy

The value set in code C0122/000 is too

low.

Increase the value in code C0122/000.

Overtemperature detection by

PTC/KTY: Motor too hot due to

continuous overload/overcurrent

Check the drive dimensioning.

No PTC/KTY connected

Connect PTC/KTY.

Deactivate the OH7 error by setting code C0584/000

= 3).

57

OH7

The value set in code C0121/000 is too

low.

Increase the value in code C0121/000.

Overtemperature detection by

temperature contact: Motor too hot

due to continuous

overload/overcurrent

Check the drive dimensioning.

58

OH8

No temperature contact connected

Connect a temperature contact to terminals T1/T2.

Deactivate the OH8 error by setting code C0585/000

= 3).

61

CE0

Fault during transmission of control

commands via AIF interface (e.g.

PROFIBUS DP)

Plug the automation module in securely.

Screw the automation module tight.

62

CE1

CAN-IN1 channel receiving no data or

faulty data

Check the CAN bus line (connector X4).

Check the CAN terminating resistors (on the first and

last CAN nodes).

Check the configuration of the CAN node sending to

CAN-IN1.

Check the voltage supply of the CAN node sending

to CAN-IN1.

Check and if necessary increase the monitoring time

in code C0357/001.

63

CE2

CAN-IN2 channel receiving no data or

faulty data

Check the CAN bus line (connector X4).

Check the CAN terminating resistors (on the first and

last CAN nodes).

Check the configuration of the CAN node sending to

CAN-IN2.

Check the voltage supply of the CAN node sending

to CAN-IN2.

Check and if necessary increase the monitoring time

in code C0357/002.

64

CE3

CAN-IN3 channel receiving no data or

faulty data

Check the CAN bus line (connector X4).

Check the CAN terminating resistors (on the first and

last CAN nodes).

Check the configuration of the CAN node sending to

CAN-IN3.

Check the voltage supply of the CAN node sending

to CAN-IN3.

Check and if necessary increase the monitoring time

in code C0357/003.

65

CE4

Controller has received too many

faulty telegrams via the CAN bus and

has disconnected itself from the bus.

Check the baud rates of all nodes.

Check the wiring:

-

Check the bus terminating resistors.

-

Check the shield connection on the cables.

-

Check the PE connection.

-

Check the bus load.

-

Reduce the baud rate (CAUTION: Take the CAN

bus cable lengths into account).

66

CE5

CAN time-out (gateway function

C0370)

Check the settings in code C0370/000.

70

U15

Undervoltage internal 15 V supply

voltage

Check the control voltage for voltage fluctuations or

voltage dips.

Processor is overloaded or a program

flow error has occurred.

Reduce the processor load: Remove function blocks

which are not required from the processing table

(C0465/0xx).

Significant interference injections on

the control cables

Install shielded control cables.

71

CCr

Earth loops in the wiring

Make sure that the wiring is EMC-compliant (see

"9300" System Manual, p. 4-34).

72

Pr1

Error transmitting the parameter set

CAUTION: The default setting is

loaded automatically!

Set the required parameters and save them to non-

volatile EEPROM via code C0003/000.

73

Pr2

Error transmitting the parameter set

CAUTION: The default setting is

loaded automatically!

Set the required parameters and save them to non-

volatile EEPROM via code C0003/000.