6 calctpdistance function block, Variable names, Calctpdistance function block -95 – Lenze EVS93xx CrossCutter User Manual

Page 263: Cross cutter, Appendix

Cross Cutter

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

6-95

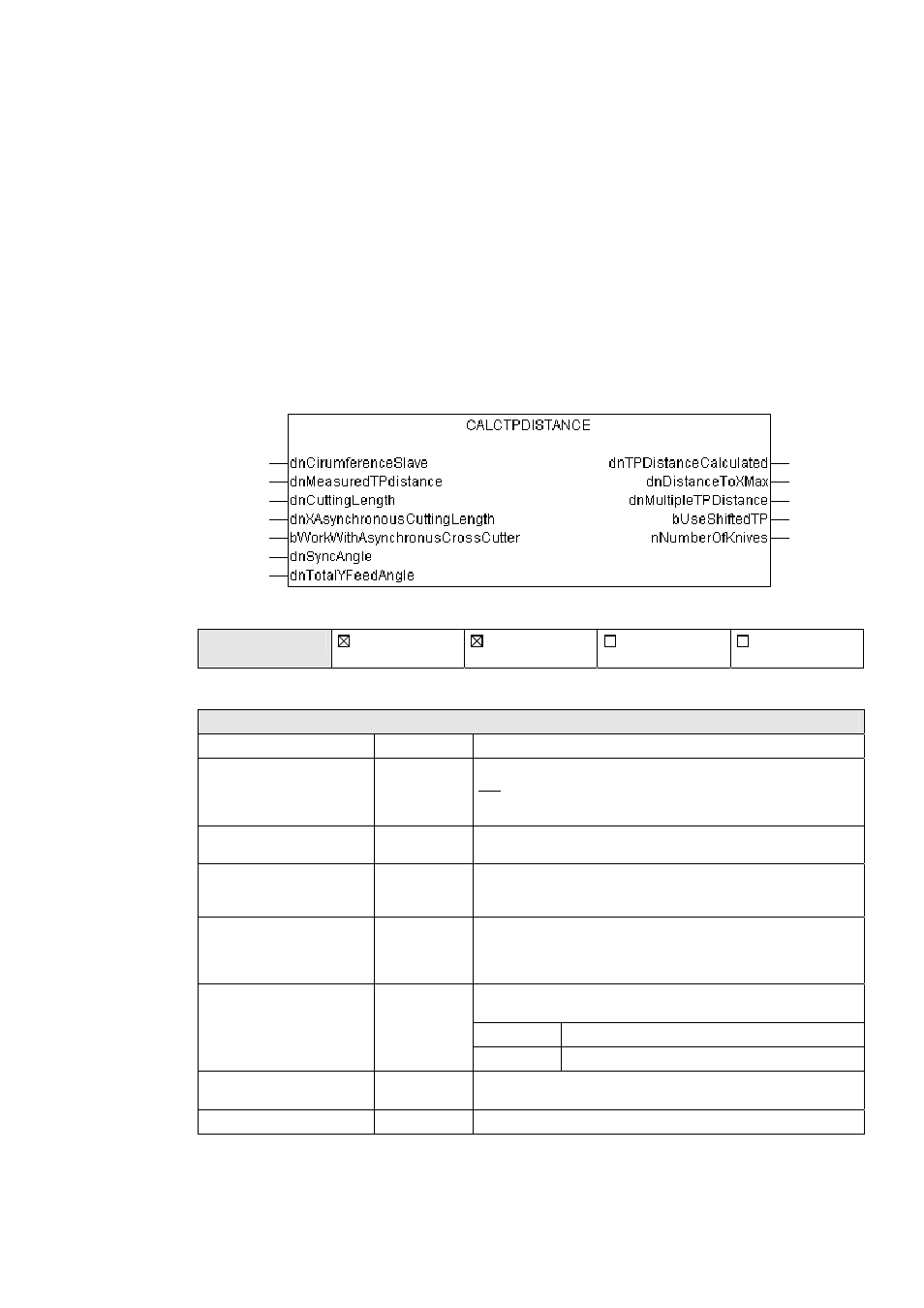

6.6.6 CalcTpDistance function block

The CalcTpDistance function block uses the cross-cutter application's input variables to

calculate the following output values:

• The print-mark-sensor distance

• The distance from the 6 o'clock position of the knife to the x max. value of the profile

• The value indicated by the distance of the touch-probe sensor in integer multiples of

the cutting length

• The number of knives mounted on the cross-cutter drum are also calculated.

Task information

Can be called in:

Cyclic task

Time-controlled task

(INTERVAL)

Event-controlled task

(EVENT)

Interrupt task

Variable

names

Inputs

(Variable type: VAR_INPUT)

Name Data

type

Value/Meaning

dnCircumferenceSlave

DINT

Cutting circle circumference of the knife drum in 0.0001[m_units].

Note: Do not enter the synchronous cutting length here (on knife drums with more

than one knife, this may not be the same as the cutting circle circumference). You

should always enter the entire circumference of the knife's cutting circle.

dnMeasuredTPdistance DINT Distance

measured from TP sensor to 6 o'clock position on the knife drum. The

value is entered in 0.0001[m_units].

dnCuttingLength

DINT

Cutting length of the material. The value is entered in 0.0001[m_units]. You can also

link this input variable directly to output variable dnActCuttingLength in the

CrossCutterMotionProfileCalculation FB.

dnXAsynchronousCuttingLength

DINT

Length of the profile in which the cross cutter moves asynchronously in relation to

the material;. The value is entered in 0.0001[m_units]. You can also link this input

variable directly to output variable dnXAsynchronousLength in the

CrossCutterMotionProfileCalculation FB.

Change-over of calculation formula in accordance with the type of cross cutter being

used.

TRUE

Using the calculation for the asynchronous cross cutter.

bWorkWithAsynchronusCrossCutter BOOL

FALSE

Using the calculation for the synchronous cross cutter.

dnSyncAngle

DINT

Cutting angle for which the knife has to run in synchronism with the material (y

sync

,

the value is entered in 0.0001[s_units]).

dnTotalYFeedAngle

DINT

Y final value of the selected motion profile in 0.0001[s_units].