Cross cutter, Appendix – Lenze EVS93xx CrossCutter User Manual

Page 217

Cross Cutter

Appendix

Prepared Solution Servo PLC / ECSxA 1.1 EN

6-49

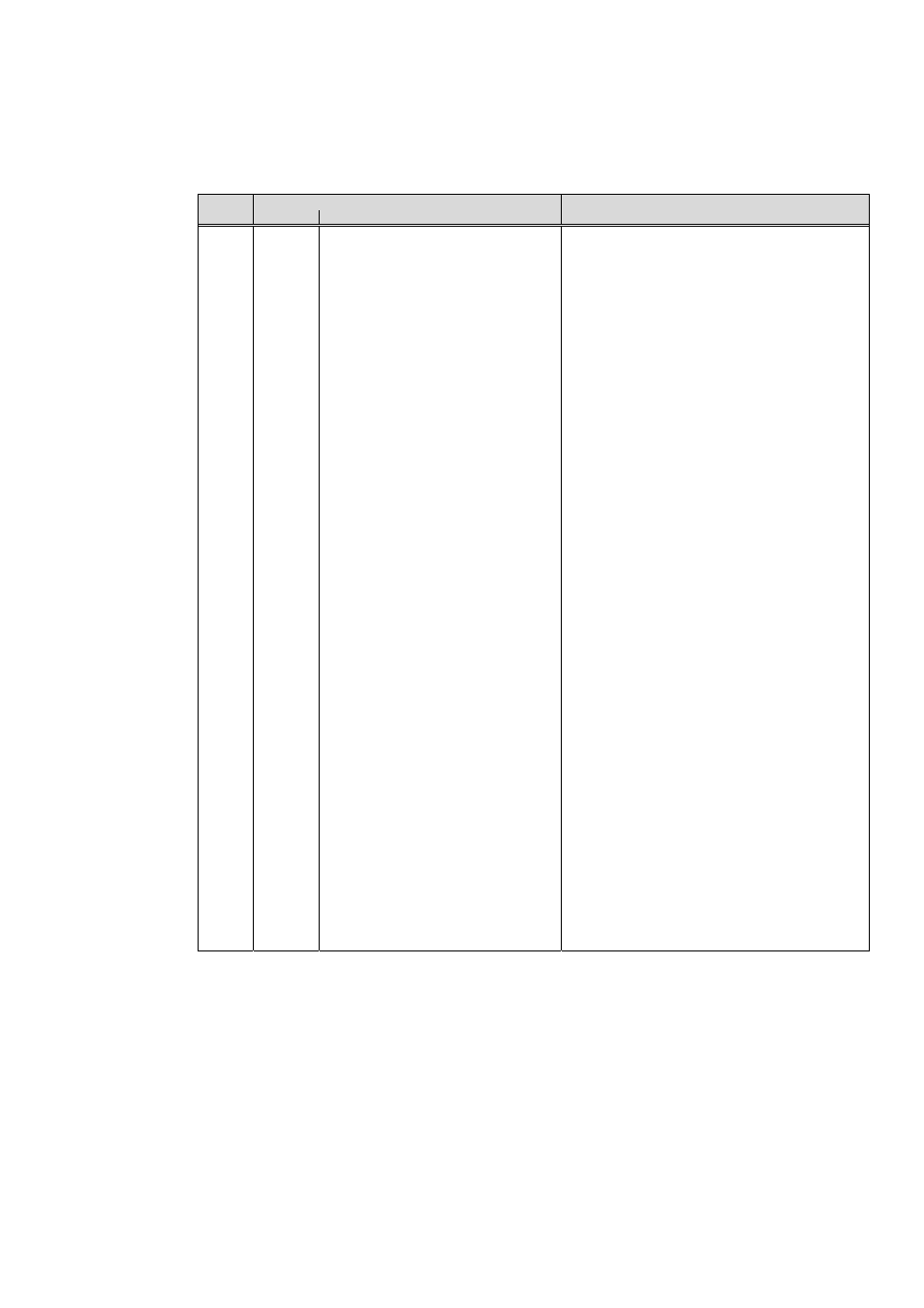

Possible settings:

Code

Default

Selection

Comment

C4012/

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

021

022

023

024

025

026

027

028

029

030

031

032

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

0 {1}

31 Configuration codes for the status interface: Each subcode

defines, for a specific status bit, the source of the status

information:

The single subcodes are assigned with the following Bits:

001:

Bit 0

002:

Bit 1

….

032:

Bit 31

The following status information, can be assigned free of choice

to the 31 Bits:

0: Trip

state

1:

Follow error warning

2: Follow

error

trip

3: Positioning

active

4: Positioning

done

5:

Lock to cam busy

6:

Cross Cutter Operation

7:

Print mark correction active

8:

Recalculation of cutting profile

9:

Recalculation of reject profile

10:

Recalculation of test profile

11:

Recalculation of start/stop profile

12:

Calculation of cutting profile OK

13:

Calculation of reject profile OK

14:

Calculation of test profile OK

15:

Calculation of start/stop profile OK

16: Homing

busy

17:

Home position available

18: Homing

error

29: NC

20:

asynchronus cutting operation

21:

synchronus cutting operation

22: Cutting

mode

23: Reject

mode

24: Test

mode

25:

Open reject gate

26:

Maximum missed marks exceeded

27:

Print mark controller enabled

28:

Print mark register active

29:

Knife in material (sync angle)

30: NC

31:

Profile calculations done

The cross-cutter axis can be monitored via the status interface.

The default values are set via code initialisation.