Cross cutter – Lenze EVS93xx CrossCutter User Manual

Page 90

Cross Cutter

Features of the "Cross Cutter" prepared solution

Prepared Solution Servo PLC / ECSxA 1.1 EN

2-76

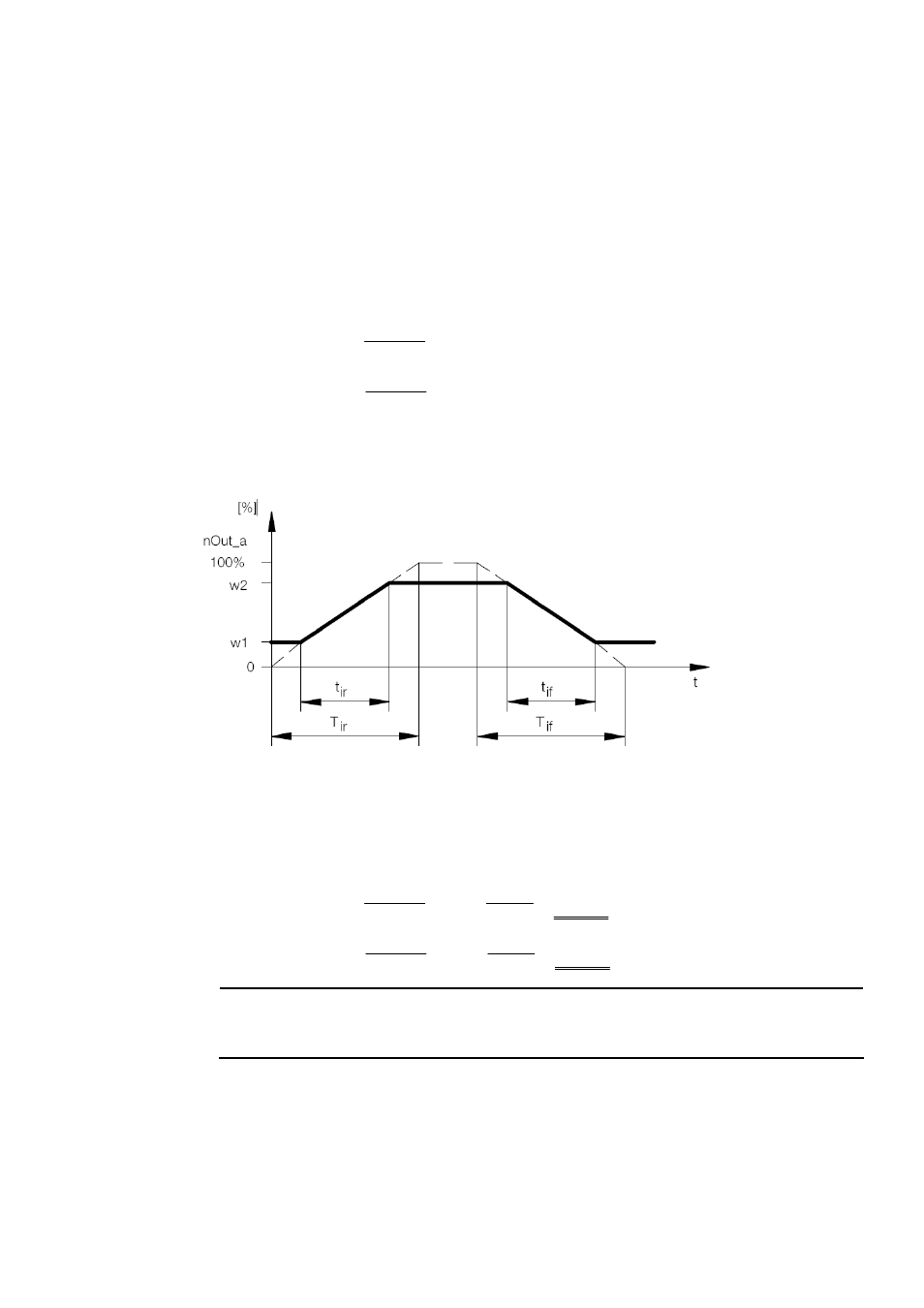

Calculating and setting acceleration and deceleration times when using inching trimming

(g_bXAxisTrimmingPosDirection and g_bXAxisTrimmingNegDirection)

The acceleration and deceleration times relate to a change in the output value from 0 to 100%

(100% = 16384). The times to be set for the acceleration time Tir and the deceleration time Tif

can be calculated using the following formulae:

1

2

%

100

1

2

%

100

w

w

t

T

on

decelerati

w

w

t

T

on

accelerati

if

if

ir

ir

−

⋅

=

−

⋅

=

Following calculation, you will need to enter the values T

ir

and T

if

in the corresponding codes

(C3676/000 = acceleration time T

ir

; C3677/000 = deceleration time T

if

).

Figure29: Graph for calculating acceleration and deceleration times when using inching

trimming

Example: The inching speed is to be 50 rpm. This speed value needs to be reached within 1

sec. This results in the following values for T

ir

and T

if

when the formula below is applied:

sec

300

0

50

15000

sec

1

1

2

%

100

sec

300

0

50

15000

sec

1

1

2

%

100

=

−

⋅

=

−

⋅

=

=

−

⋅

=

−

⋅

=

w

w

t

T

on

decelerati

w

w

t

T

on

accelerati

if

if

ir

ir

Note!

100% corresponds to the value entered in code C0011/000. In the example calculation, a

value of 15,000 rpm has been assumed.

Calculating and setting acceleration and deceleration times when using position

trimming (C3674/000 = Selection of the absolute target trimming position)

The acceleration and deceleration times relate to 4000 rpm. The times to be set for the

acceleration time T

ir

and the deceleration time T

if

can be calculated using the following

formulae: