IAI America XSEL-QX User Manual

Page 533

509

Appendix

(In the pan

el wind

ow, the thre

e digits aft

er “E” in

dicate an erro

r nu

mber.

)

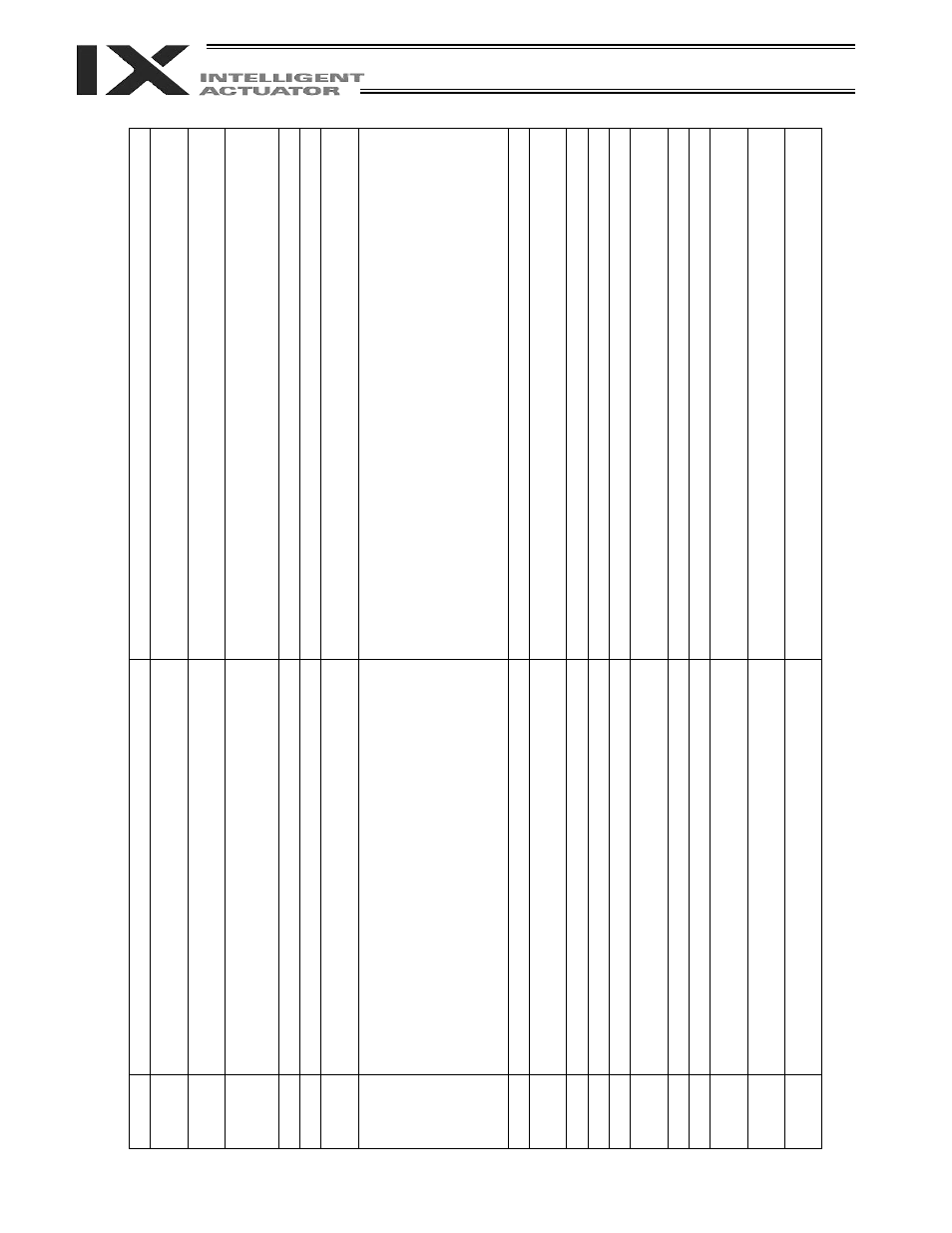

Error No.

Error name

Description, ac

tion, etc.

CB9

PX/PY-a

xis ind

etermina

bl

e err

or at pall

etizin

g

angl

e acqu

isit

ion

Angl

e cannot be calcul

ated b

e

c

ause ther

e ar

e too man

y

val

id axes in the

3-point

teachi

ng dat

a and thus P

X

/P

Y-axes can

not be spec

ified.

CBA

Reference-axis

/PY/PY-ax

is mismatch error at

palletiz

ing angle

acquis

ition

Angl

e cannot be calcul

ated because the refer

ence a

x

is for angle c

a

lcu

latio

n is

neither of the ax

es com

prising the PX

/PY-axes as set by

3-

point teac

hing.

CBB

Refere

nce-p

oi

nt/PX-a

xis end

-point dupl

icati

on error at pall

etizing

angl

e acq

uisiti

on

Angl

e cannot be calcul

ated because the refer

ence p

o

int of 3

-point teac

hin

g

is the

same as the P

X

-a

xis en

d-po

in

t data other

than the PZ-axis

component and thus arc

tangent cannot be calculated.

CBC

Palletiz

ing moti

on calc

ulati

on

error

T

rapezoid cont

rol calcu

latio

n

error for pall

eti

zing moti

on

CBD

MOD command divisor

0 error

“0”

w

a

s specifi

ed as the div

is

or in the MOD command.

CBE

T

a

rget track bound

ar

y

over err

or

T

he target position or movem

ent locus

e

x

c

e

eds the pos

itio

ning

bou

nd

ar

y

in the

infinite-strok

e

mode. Cartes

ian axis onl

y

.

CBF

Positioning dist

ance ov

erflo

w

error

T

he positioni

ng distance is too large.

If,

w

ith

an abs

olute enc

oder s

pecification, this error occurred after relocating the

s

y

stem or

w

hen an “Error No.

C74, Actual

-position s

o

ft limit over error” is also

present, a servo packet calc

ul

ation ov

erflo

w

may

have occ

urred due to an i

n

vali

d

current pos

ition because an absol

ute reset

w

a

s not e

x

ec

uted correctl

y

. E

x

ec

ute an

absol

ute reset

agai

n b

y

foll

o

w

ing the pr

oced

ure in the o

per

ation ma

nua

l.

(“Resetting

an

encoder error”

in the abs

olut

e reset

w

indo

w

alone

w

ill not cause the

controller to recogniz

e the cur

rent positi

on correctl

y

. Al

w

a

ys execute an abs

olute

reset by

follo

w

ing the spec

ified procedure.)

CC0

Axis mode err

or

T

he axis mode is invali

d.

CC1

Spee

d cha

nge

conditi

on err

or

An attempt

w

a

s made to

cha

nge the speed of an ax

is

w

hose speed cannot be

changed (axis oper

ating in S-motion, etc.).

CC2

Driver par

amet

er list number error

T

he

driver para

meter list num

ber is inv

alid.

CC3

Angl

e error

T

he angle is invalid.

CC4

SEL data error

T

he SEL data is invali

d.

CC5

Positioning boundar

y

pul

l-out

error

An attempt

w

a

s

made to exec

ute a command not permitted outside the

positioni

ng

bou

ndar

y.

CC6

Driver error pr

imar

y

detection

A driver error

w

a

s found by

primar

y

detection.

CC7

Palletiz

in

g mov

ement PZ-a

xis

pattern no

n-d

etection err

or

PZ-a

xis com

ponent is not found in the axis pattern duri

ng palletiz

ing mov

ement.

CC8

Arch top Z-axis

pattern non-detection error

Z-axis com

ponent relati

ng to the hi

ghest p

o

in

t of arch motion is not foun

d i

n

t

he a

x

is

pattern dur

ing

arch motion operation.

CC9

Arch trigger Z-axis pattern non-detection err

or

Z-axis com

pon

ent relati

ng to arch motion is not found i

n

the axis pattern

o

f the

arch-trigger declaration point data.

CCA

Arch top/end-

p

o

int reversi

ng

error

T

he coordinate

s of

highest poi

n

t and end poi

n

t are reversed during arch m

o

tion

oper

ation.