Starting a new agx job – Seed Hawk Raven 2012 User Manual

Page 77

5

Manual No. 016-3001-003

65

Using the Seed Hawk® Viper Pro System

Product Chaining

The product chaining feature allows the field computer to link product tanks or bins together in series while

applying product to a field. When one tank or bin runs out, Viper automatically switches to another tank or bin

and keeps applying product reducing trips to a nurse tank or tender truck to refill products.

Note:

When chaining Seed Hawk air cart bins, the Viper Pro is configured to automatically advance

when the bin level sensor detects the bin falls below five percent.

The product chaining feature is not available with ground drive Base systems.

Be sure the field computer is set up or equipped as follows:

•

The products being chained must have their valve type setup as either “Fast Close” or “PWM Close” before

enabling product chaining.

•

The Vac/Bin Alarm and Low Tank Alarm must be set up and turned on before beginning product chaining if

either of these options is selected as an Auto Advance method.

•

The tank volume should be set up before starting a job. If advance on low tank alarm is selected and the

tank volume is zero, bin chaining will immediately advance product control to the next tank.

•

If Advance on Bin Level Sensor Alarm is to be used, all products in the chain must be equipped with a bin

level sensor.

Refer to the Starting a Standard Job section on page 73 or Starting a Standard Job section on page 73 for

information on enabling the product chaining feature when setting up a job. See Chapter 7, Product Chaining,

for details on using the product chaining feature during a job.

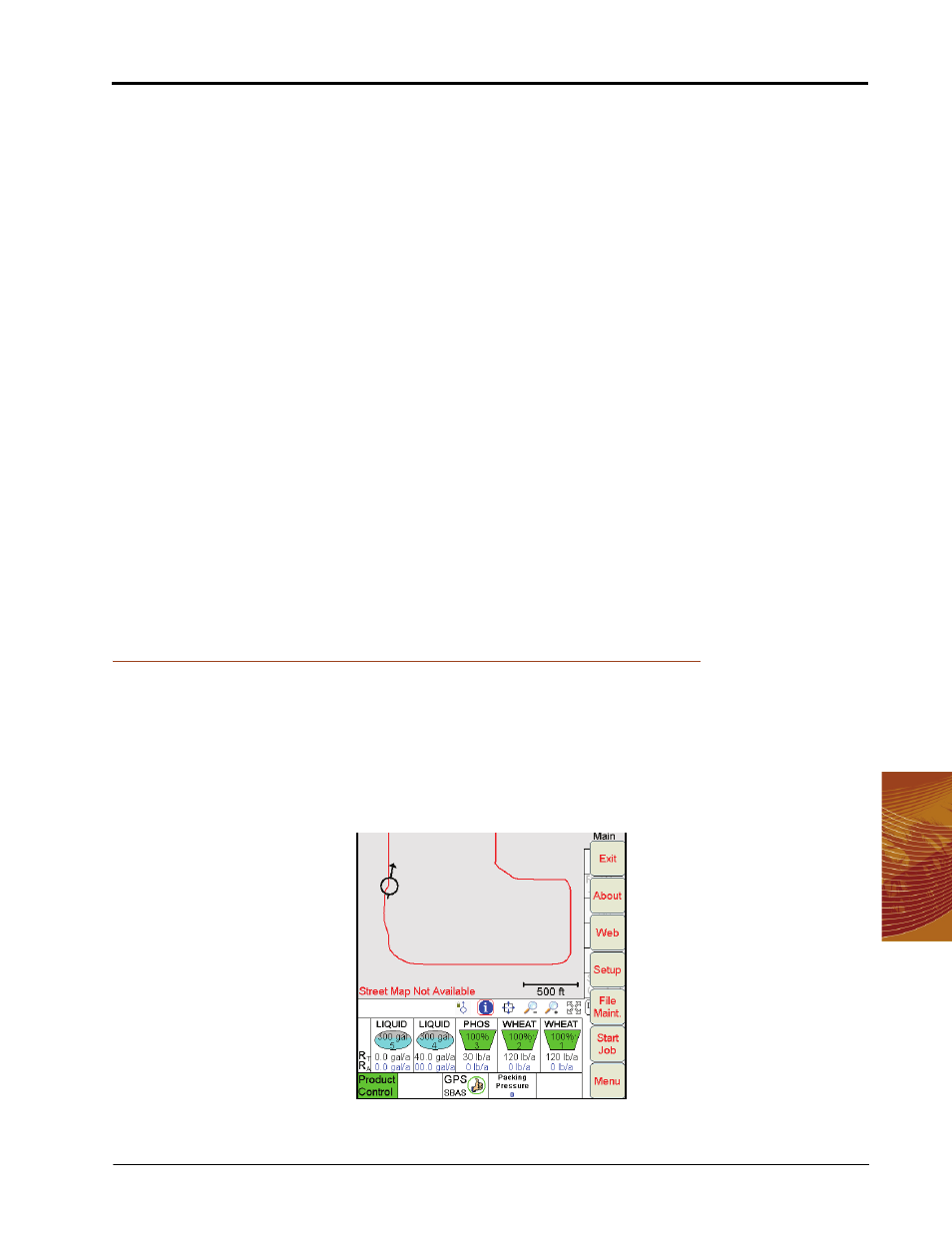

Starting a New AgX Job

Note:

Make sure all nodes connected to the CANbus are recognized and programmed correctly. Refer to

Chapter 4, Initial Set Up and Navigation if nodes do not appear to be recognized by the field

computer.

To begin a job using AgX recommendations and pre-populated job and product information:

1.

Select Menu, then Start Job.