Seed Hawk Raven 2012 User Manual

Page 146

Chapter 8

134

Seed Hawk® Viper Pro™ Installation & Operation Manual

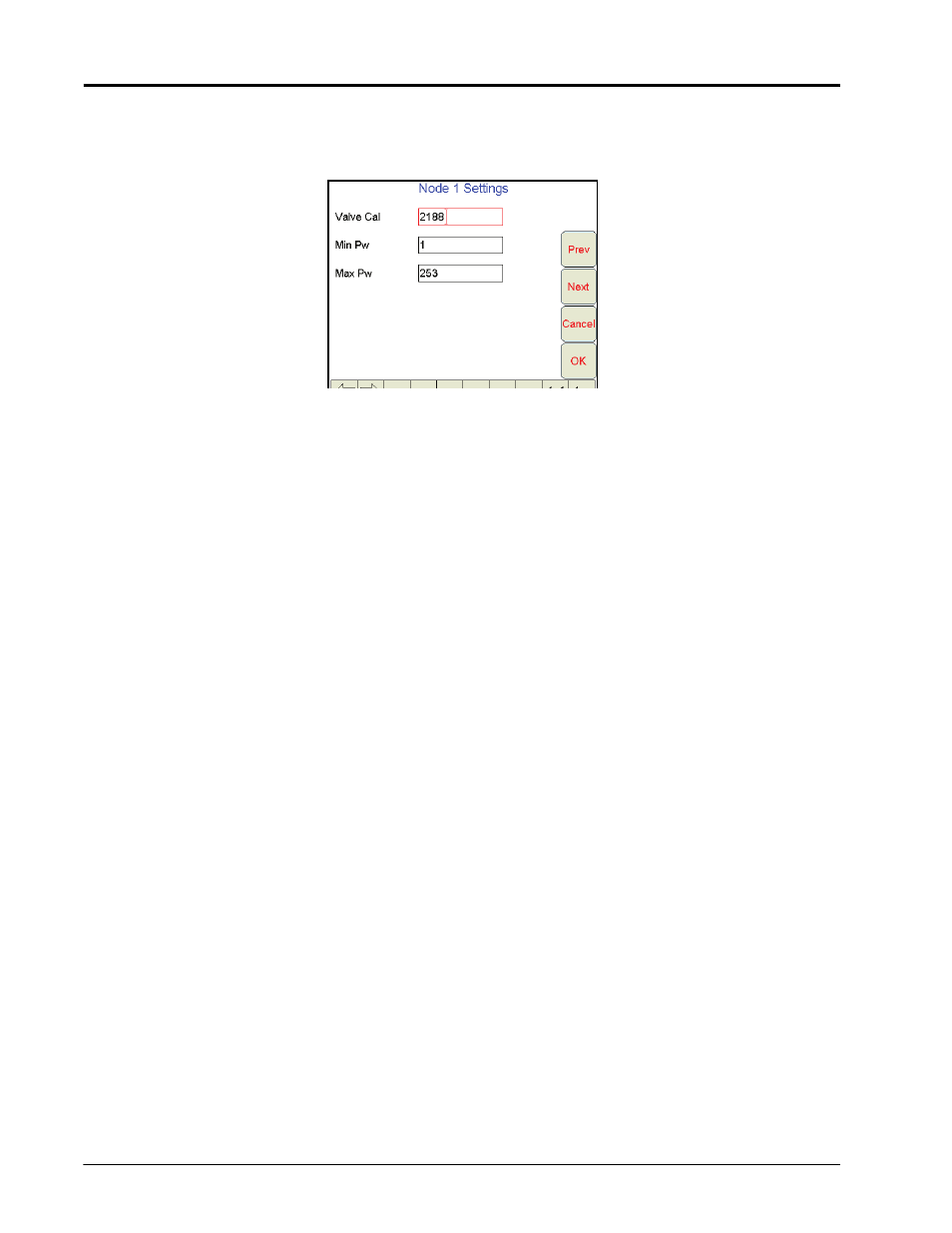

Node Settings Screen (Page 2)

Touch within the Product Control Settings area and then select the Next button on the first Node Settings

screen to access the following settings.

Valve Cal. The valve cal value is used by the field computer to make adjustments to a product or hydraulic

control valve connected to the CANbus system. Refer to the Valve Cal(s) section on page 36 for information on

the recommend initial valve cal and valve cal 2 values. Instructions for refining the product or hydraulic control

valve using the valve cal values may be found in Appendix C, Calculating the Calibration Values.

Note:

When operating a hydraulic drive system at extremely low seed application rates, the valve cal

may need to be adjusted to slow the PWM close valve and keep the seed rate from fluctuating at

these low rates. Refer to the Valve Cal section on page 240 for more information about adjusting

the valve cal.

Min PW. Use the Min PW (Pulse Width) feature to set the minimum desired RPM or hydraulic output (zero

point or shutoff point) for a Pulse Width Modulated (PWM) control valve.

Note:

Min PW is not used with ground drive carts.

Max PW. Use the Max PW (Pulse Width) feature to set the maximum desired RPM or hydraulic output (zero

point or shutoff point) for a Pulse Width Modulated (PWM) control valve.

Note:

Max PW is not used with ground drive carts.

Refer to PWM Calibration Assistance section on page 241 for details on using the calibration

assistance to calculate the Min and Max PW values.

Node Settings Screen (Page 3)

Pre Set PW. Use the pre-set PW (Pulse Width) setting to set an initial target pulse width value when using a

valve that is programmed in PWM Close mode. Enter a value between 1 (slow pulsed width) to 255 (full-scale

pulsed width). Viper uses this value to send an initial pulse width to the valve when the booms or nodes are

turned on. When a value is entered in this field, the PWM output will not exceed this value when any sections

with a non-zero boom cal are off.

When the pre-set PW value is set to zero, the initial pulse width will be equal to the previous state.

Note:

Pre Set PW is not used with ground drive carts.

When operating with hydraulic drive systems, the Pre Set PW value may need to be adjusted for

low seed rate operations if the system initially applies too high of a seed rate when turning on

sections.