Watlow EZ-ZONE RMC User Manual

Page 222

Watlow EZ-ZONE

®

RMC Module

•

219

•

Chapter 8 Appendix

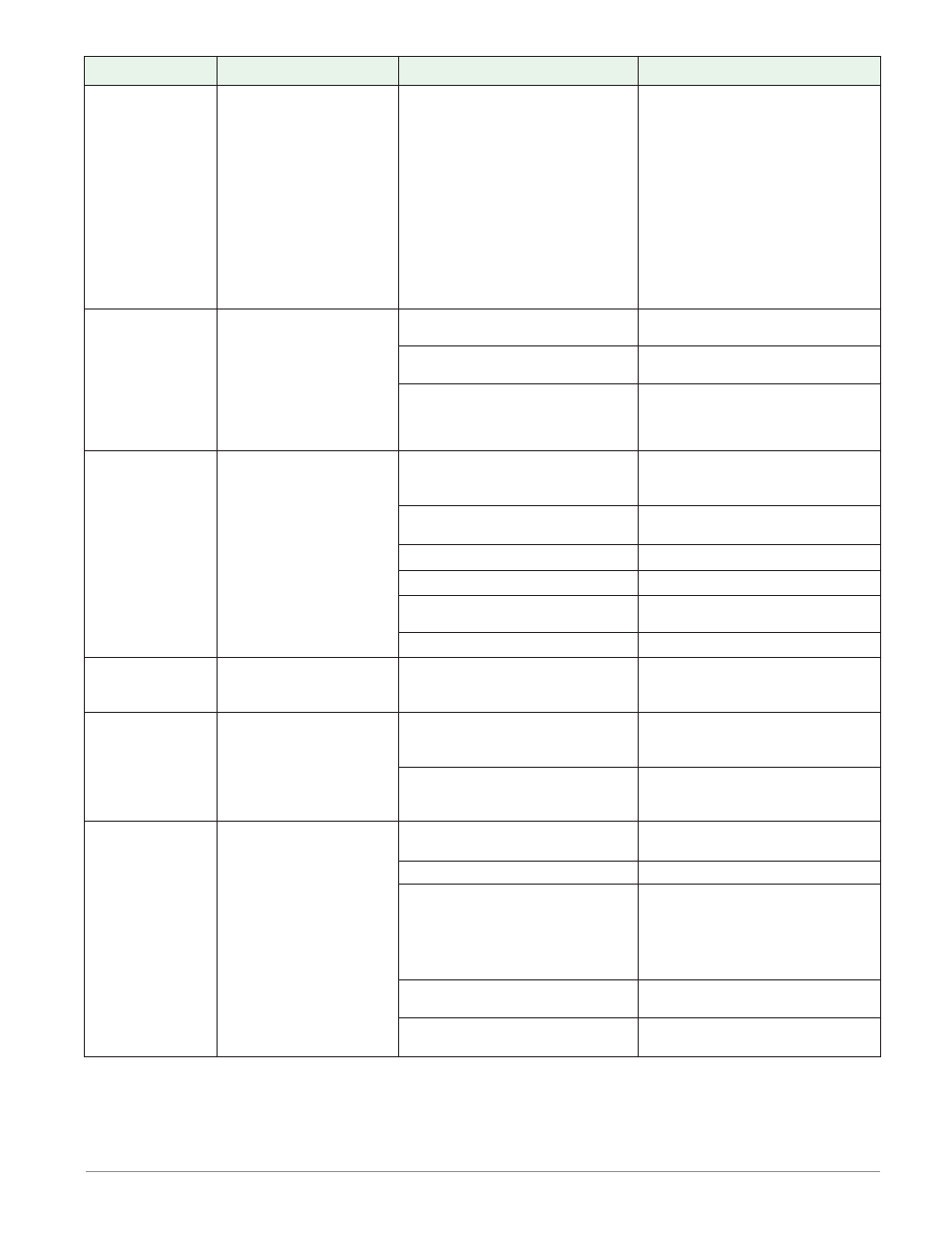

Indication

Description

Possible Cause(s)

Corrective Action

No Serial Communi-

cation

Cannot establish serial com-

munications with the con-

troller

• Address parameter incorrect

• Incorrect protocol selected

• Baud rate incorrect

• Parity incorrect

• Wiring error

• EIA-485 converter issue

• Incorrect computer or PLC communi-

cations port

• Incorrect software setup

• Wires routed with power cables

• Termination resistor may be required

• Set unique addresses on network

• Match protocol between devices

• Match baud rate between devices

• Match parity between devices

• Correct wiring issue

• Check settings or replace converter

• Set correct communication port

• Correct software setup to match con-

troller

• Route communications wires away

from power wires

• Place 120 Ω resistor across EIA-485

on last controller

Process doesn’t con-

trol to set point

Process is unstable or never

reaches set point

• Controller not tuned correctly

• Perform autotune or manually tune

system

• Control mode is incorrectly set

• Set control mode appropriately (Open

vs Closed Loop)

• Control set point is incorrect

• Set control set point in appropriate

control mode and check source of set

point: remote, idle, profile, closed loop,

open loop

Temperature runway Process value continues to

increase or decrease past set

point.

• Controller output incorrectly pro-

grammed

• Verify output function is correct (heat

or cool)

• Thermocouple reverse wired

• Correct sensor wiring (red wire nega-

tive)

• Controller output wired incorrectly

• Verify and correct wiring

• Short in heater

• Replace heater

• Power controller connection to con-

troller defective

• Replace or repair power controller

• Controller output defective

• Replace or repair controller

Device Error

[`100]

[rEtn]

Controller displays internal

malfunction message at

power up.

• Controller defective

• Sensor input over driven

• Replace or repair controller

• Check sensors for ground loops, re-

verse wiring or out of range values.

Heater Error

[`h;Er]

Heater Error

• Current through load is above current

trip set point

• Check that the load current is proper.

Correct cause of overcurrent and/or en-

sure current trip set point is correct.

• Current through load is below current

trip set point

• Check that the load current is proper.

Correct cause of undercurrent and/or

ensure current trip set point is correct.

Current Error

[`C;Er]

Load current incorrect.

• Shorted solid-state or mechanical

relay

• Replace relay

• Open solid-state or mechanical relay • Replace relay

• Current transformer load wire associ-

ated to wrong output

• Route load wire through current

transformer from correct output, and

go to the [`C;Si] Source Output In-

stance parameter (Setup Page, Current

Menu) to select the output that is driv-

ing the load.

• Defective current transformer or con-

troller

• Replace or repair sensor or controller

• Noisy electrical lines

• Route wires appropriately, check for

loose connections, add line filters