Cascade control, Compressor control, Differential control – Watlow EZ-ZONE RMC User Manual

Page 165

Watlow EZ-ZONE

®

RMC Module

•

162

•

Chapter 7 Features

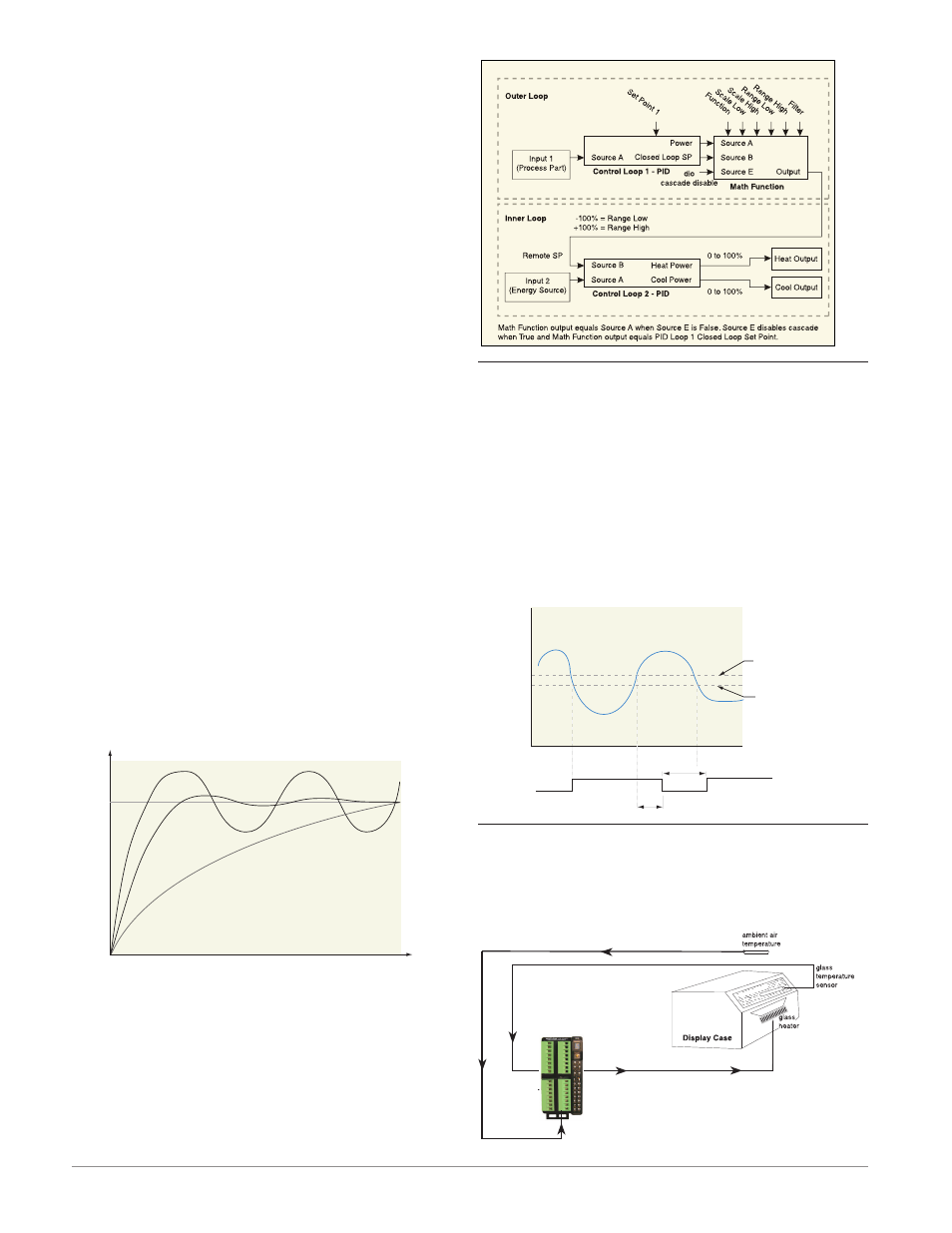

Cascade Control

Cascade control is a control strategy in which one

control loop provides the set point for another loop. It

allows the process or part temperature to be reached

quickly while minimizing overshoot. Cascade is used

to optimize the performance of thermal systems with

long lag times. The graph on the next page illus-

trates a thermal system with a long lag time.

Curve A represents a single loop control system

with PID parameters that allow a maximum heat

up rate. Too much energy is introduced and the

set point is overshot. In most systems with long lag

time, the process value may never settle out to an ac-

ceptable error. Curve C represents a single control

system tuned to minimize overshoot. This results in

unacceptable heat up rates, taking hours to reach

the final value. Curve B shows a cascade system that

limits the energy introduced into the system, allow-

ing an optimal heat up rate with minimal overshoot.

Cascade control uses two control loops (outer and

inner) to control the process. The outer loop (analog

input 2) monitors the process or part temperature,

which is then compared to the closed loop set point.

The result of the comparison, the error signal, is

acted on by the PID settings in the cascade outer

loop, which then generates a power level for the outer

loop. The set point for the inner loop is determined

by the outer loop power level. The inner loop input

(any input) monitors the energy source (heating and

cooling), which is compared to the inner loop set

point generated by the outer loop. The result of the

comparison, the error signal, is acted on by the PID

settings in the cascade inner loop, which generates

an output power level between -100% to +100%. If

the power level is positive the heat will be on; if the

power level is negative the cool will come on. Power

from the energy sources are supplied by the outputs

of choice.

Time

Temperature

Cascade

Curve A (PID)

Set

Point

Curve B (Cascade)

Curve C (Single-control)

Cascade

Compressor Control

The compressor control can save wear on a compres-

sor and prevent it from locking up from short cycling.

A bypass valve operated by a control output regu-

lates how the process is cooled, while another output

switches the compressor on and off. The compressor

will not turn on until the output power exceeds the

Compressor On % Power for a time longer than the

Compressor On Delay. The compressor will not turn

off until the output power exceeds the Compressor

Off % Power for a time longer than the Compressor

Off Delay.

0% Compressor

On Power

Off

On

100%

2%

0%

-100%

Compressor On Delay = 45 Seconds

Compressor Off Delay = 20 Seconds

2% Compressor

Off Power

Time In Seconds

% Power

Heat

Cool

Compressor

Differential Control

After configuring the appropriate inputs and their

associated internal functions Differential Control al-

lows the RMC to drive an output based on the differ-

ence between those analog inputs.

Input 1

Input 2

Output 1