Alarms, Ratio control, Motorized valve control – Watlow EZ-ZONE RMC User Manual

Page 166: Process and deviation alarms, Alarm set points, Alarm hysteresis

Watlow EZ-ZONE

®

RMC Module

•

163

•

Chapter 7 Features

Ratio Control

Ratio control is commonly used to ensure that two

or more flows are kept at the same ratio even if the

flows are changing; especially useful in applications

that mix materials.

Applications of ratio control:

• Blending two or more flows to produce a mixture

with specified composition.

• Blending two or more flows to produce a mixture

with specified physical properties.

• Maintaining correct air and fuel mixture to com-

bustion.

controlled flow

of pigment

flow

transmitter

motorized

valve

Mixing Tank

flow

transmitter

mixed paint

uncontrolled

flow of

unmixed paint

Input 2

Input 1

Output 1

Motorized Valve Control

A motorized valve is used is to regulate the flow of

fluid which in turn impacts the loop process value. A

valve is opened or closed by closing contacts to drive

the value in the intended direction. This feature is

configured by selecting Motorized Valve as the func-

tion in the Setup Page, Special Output Function

menu. Source Function A is selected for either Heat

or Cool Power then entering the Valve Travel Time

and Deadband.

Lastly, program the outputs which will open and

close the valve. The algorithm will calculate Dead

Time which is the minimum on time that the valve

will travel once it is turned on in either the closed or

open direction. Dead Time = Valve Dead Band / 100

* Valve Travel Time.

Output 1 = Close

Temperature

Sensor

Gas Furnace

Output 2 = Open

Gas Flow

Valve

Actuator

®

Alarms

Alarms are activated when the output level, process

value or temperature leaves a defined range. A user

can configure how and when an alarm is triggered,

what action it takes and whether it turns off auto-

matically when the alarm condition is over.

Configure alarm outputs in the Setup Page before

setting alarm set points.

Alarms do not have to be assigned to an output.

Alarms can be monitored and controlled through the

front panel or by using software.

Process and Deviation Alarms

A process alarm uses one or two absolute set points

to define an alarm condition.

A deviation alarm uses one or two set points that

are defined relative to the control set point. High

and low alarm set points are calculated by adding or

subtracting offset values from the control set point.

If the set point changes, the window defined by the

alarm set points automatically moves with it.

Select the alarm type [`A;ty] via the Setup Page,

Alarm Menu.

Alarm Set Points

The alarm high set point defines the process value

or temperature that will trigger a high side alarm.

The alarm low set point defines the temperature that

will trigger a low side alarm. For deviation alarms,

a negative set point represents a value below closed

loop set point. A positive set point represents a value

above closed loop set point. View or change alarm set

points with Alarm Low [`A;Lo] and Alarm High Set

Points [`A;hi] (Operations Page, Alarm Menu).

Alarm Hysteresis

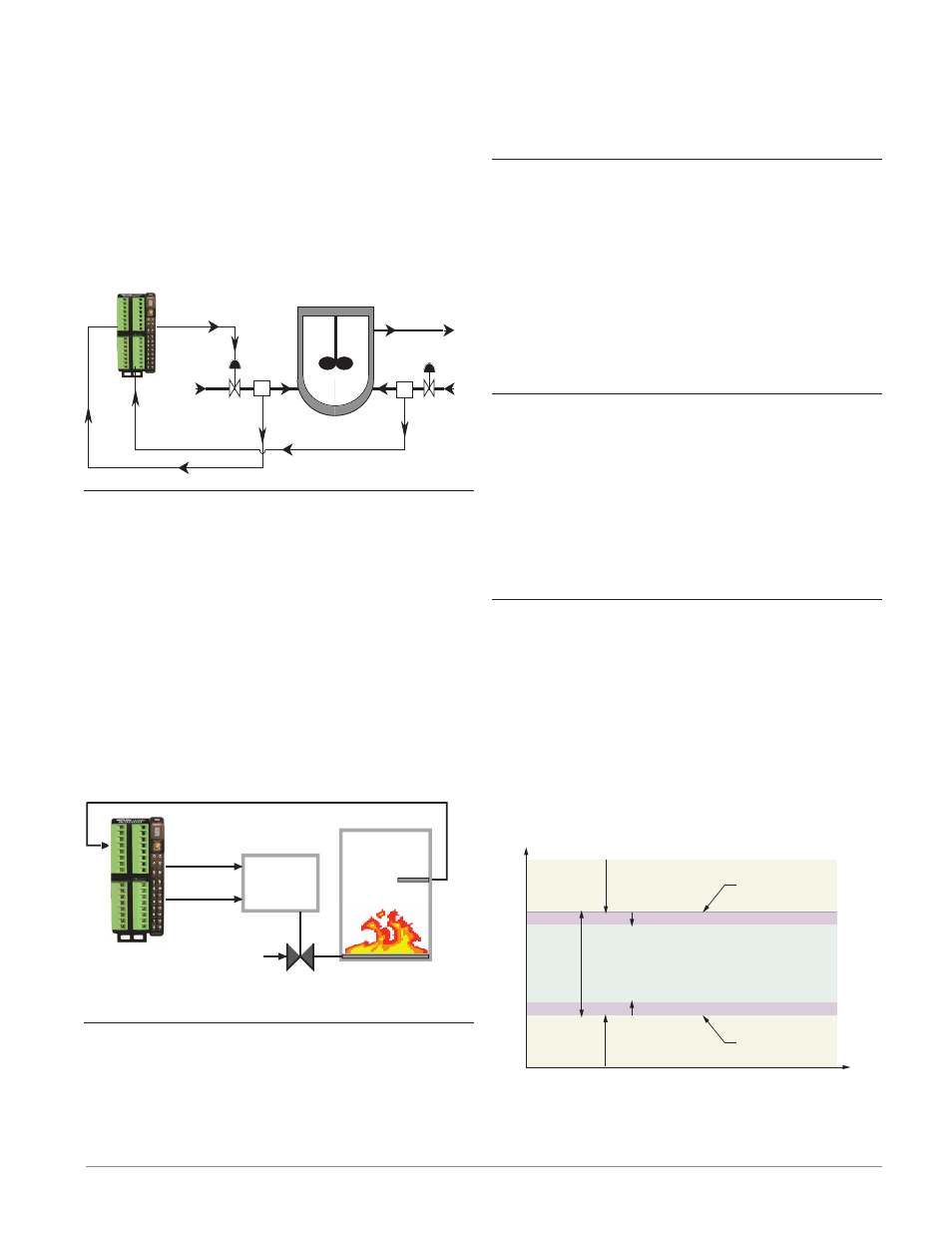

An alarm state is triggered when the process value

reaches the alarm high or alarm low set point. Alarm

Hysteresis defines how far the process must return

into the normal operating range before the alarm can

be cleared.

Alarm Hysteresis is a zone inside each alarm set

point. This zone is defined by adding the hysteresis

value to the alarm low set point or subtracting the

hysteresis value from the alarm high set point. View

or change Alarm Hysteresis [`A;hy] via the Setup

Page, Alarm Menu.

Normal Operating Range

Low Side Alarm Range

High Side Alarm Range

Alarm High Set Point

Alarm Low Set Point

Time

Temperature

Alarm Set Points and Hysteresis

Alarm Hysteresis

Alarm Hysteresis