Outputs, Range high and range low, Receiving a remote set point – Watlow EZ-ZONE RMC User Manual

Page 160: Ten point linearization, No-arc relay

Watlow EZ-ZONE

®

RMC Module

•

157

•

Chapter 7 Features

Select the low and high values with Scale Low

[`S;Lo]

and Scale High [`S;hi]. Select the displayed

range with Range Low [`r;Lo] and Range High

[`r;hi]

(Setup Page, Analog Input Menu).

Range High and Range Low

With a process input, you must choose a value to rep-

resent the low and high ends of the current or voltage

range. Choosing these values allows the controller’s

display to be scaled into the actual working units of

measurement. For example, the analog input from a

humidity transmitter could represent 0 to 100 per-

cent relative humidity as a process signal of 4 to 20

mA. Low scale would be set to 0 to represent 4 mA

and high scale set to 100 to represent 20 mA. The in-

dication on the display would then represent percent

humidity and range from 0 to 100 percent with an

input of 4 to 20 mA.

Select the low and high values with Range Low

[`r;Lo]

and Range High [`r;hi] (Setup Page, Analog

Input Menu).

Receiving a Remote Set Point

The remote set point feature allows the controller

to use a thermocouple, RTD, 1k potentiometer or

process signal (from any RM module) as the second

input to establish the set point, which allows its set

point to be manipulated by an external source. A

common application would use one ramping controller

with a set-point retransmit output to ramp multiple

controllers using the remote set point. Or you could

use an analog output from a PLC to send set point

values to an EZ-ZONE RMC. The controller must

have at least two process inputs to use the remote set

point feature.

You may select between local and remote set

points at the front panel, with an event input, from

a remote computer using the communications fea-

ture or from an external switch using an event input.

Make sure all input and output impedances are com-

patible.

Switch to the remote set point with Remote En-

able [`r;En] (Operations Page, Loop Menu). Select

whether the remote set point controls an open- or

closed-loop set point with Remote Set Point Type

[`r;ty]

.

Assign the function of switching to a remote set

point to an Action Function [``Fn] (Setup Page, Ac-

tion Menu).

Assign the function of switching to a remote set

point to the EZ Key with Digital Input Function

[``Fn]

(Setup Page, Function Key Menu).

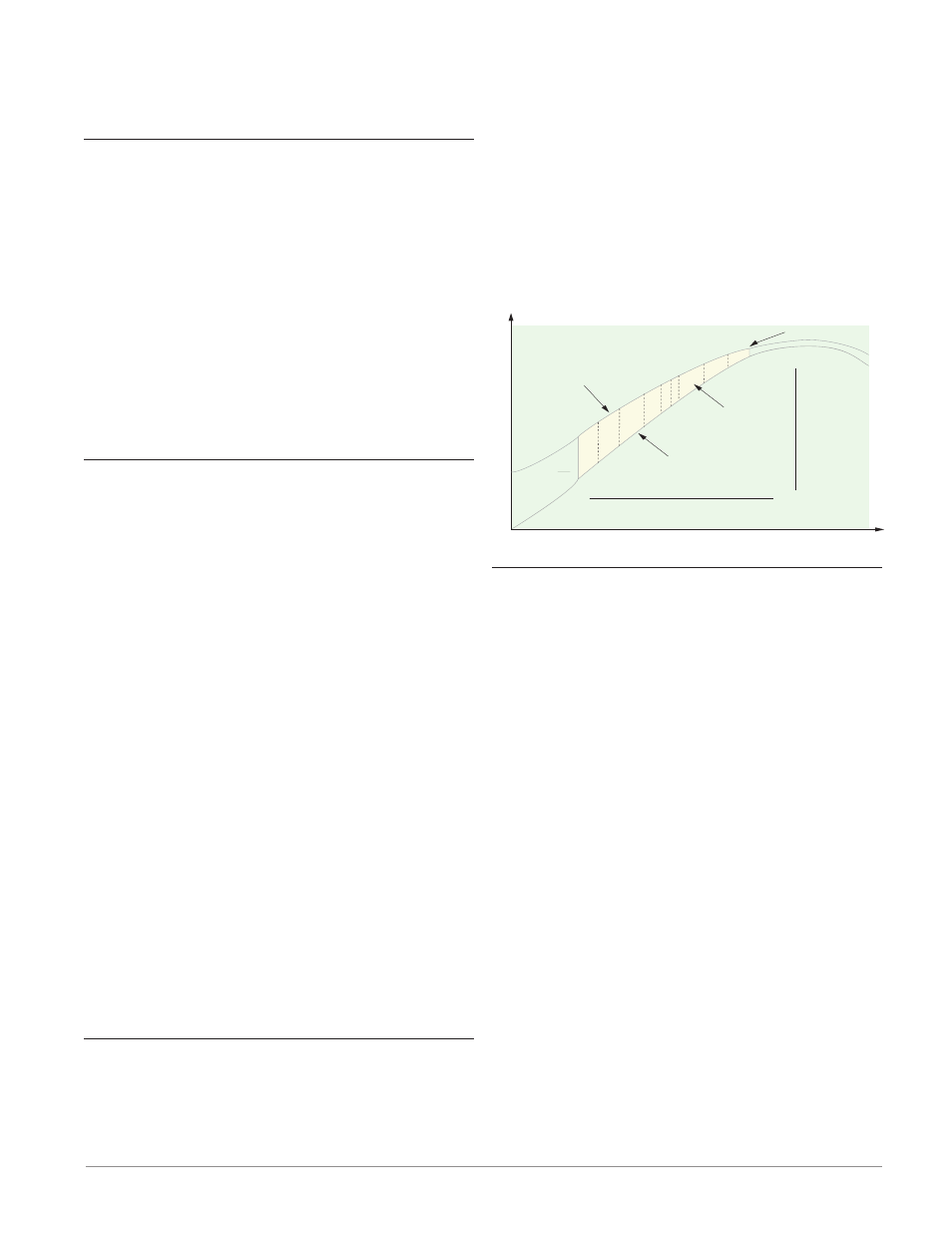

Ten Point Linearization

The linearization function allows a user to re-linear-

ize a value read from an analog source. The function

selections are Off, Interpolated and Stepped. When

set to Off the output will match the Source A value

plus offset. There are 10 data points used to compen-

sate for differences between the source value read

(input point) and the desired value (output point).

Multiple data points enable compensation for non-

linear differences between the sensor readings and

target process values over the thermal or process sys-

tem operating range. Sensor reading differences can

be caused by sensor placement, tolerances, an inaccu-

rate sensor or lead resistance.

The user specifies the unit of measurement and

then each data point by entering an input point value

and a corresponding output point value. Each data

point must be incrementally higher than the previous

point. The linearization function will interpolate data

points linearly in between specified data points.

2

3

4

5 6

7

8

9

Reading from Sensor

without Linearization

(Actual Value)

Input Point 1

Output Point 1

Input Point 10

Output Point 10

Offset Zone

Reading from Sensor

with Linearization

(Displayed Value)

No Offset

T

emperature

Time

Outputs

NO-ARC Relay

A NO-ARC relay provides a significant improvement

in the life of the output relay over conventional re-

lays.

Conventional mechanical relays have an expected

life of 100,000 cycles at the rated full-load current.

The shorter life for conventional relays is due to the

fact that when contacts open while current is flowing

metal degradation occurs. This action produces un-

avoidable electrical arcing causing metal to transfer

from one contact to the other. The arcing conditions

continue on each subsequent contact opening until

over time the resistance through the contacts in-

creases causing the contacts to increase in tempera-

ture. Eventually, the contacts will weld together and

the relay remains in the on state.

The Watlow NO-ARC relay is a hybrid relay. It us-

es a mechanical relay for the current load and a triac

(solid-state switch) to carry the turn-on and turn-off

currents. NO-ARC relays extend the life of the relay

more than two million cycles at the rated full-load

current.

Although a NO-ARC relay has significant life ad-

vantages, a few precautions must be followed for ac-

ceptable usage:

Do not use:

• Hybrid relays for limit contactors. A limit or

safety device must provide a positive mechanical

break on all hot legs simultaneously;