Proportional (p) control, Proportional plus integral (pi) control, Dead band – Watlow EZ-ZONE RMC User Manual

Page 163

Watlow EZ-ZONE

®

RMC Module

•

160

•

Chapter 7 Features

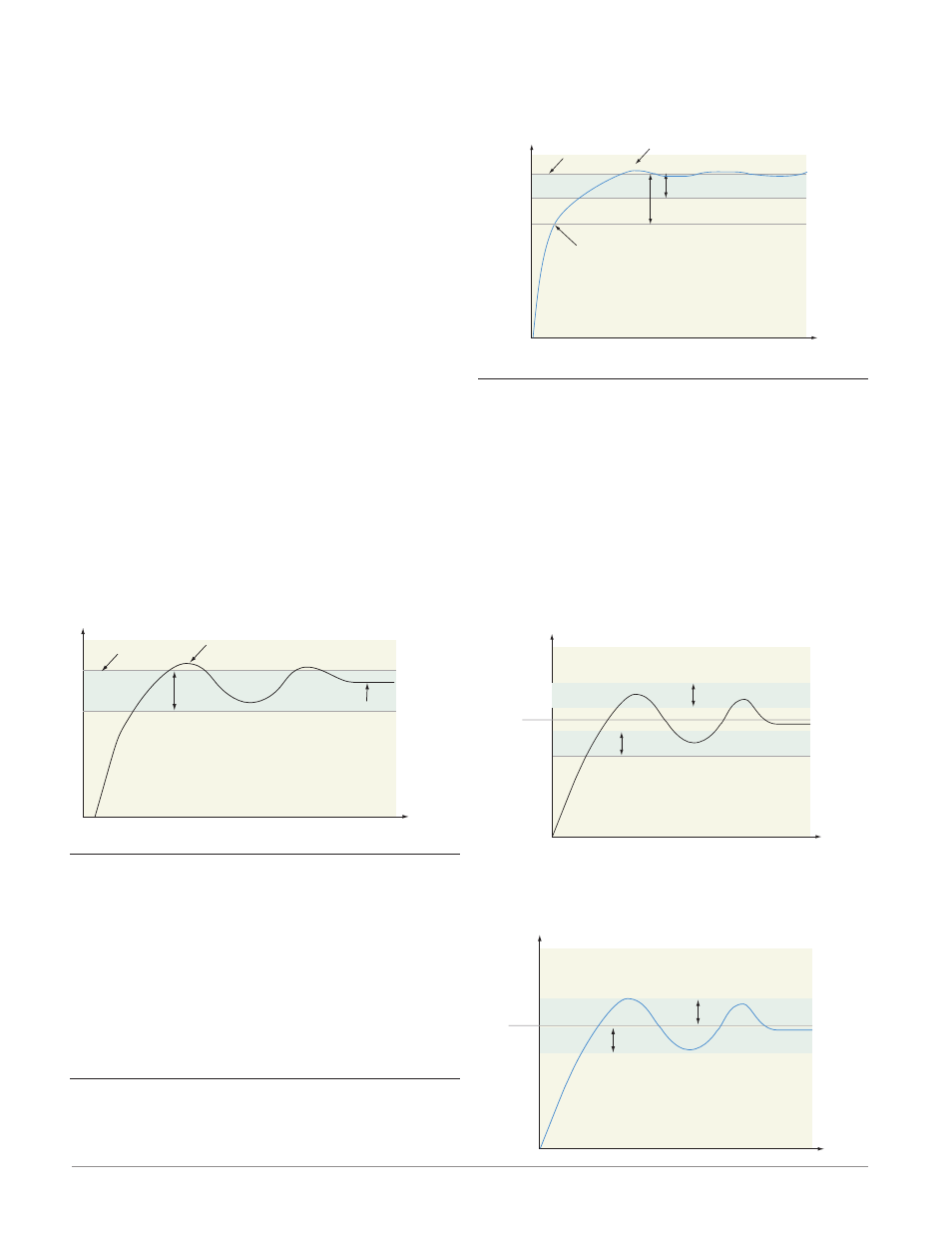

Proportional (P) Control

Some processes need to maintain a temperature or

process value closer to the set point than on-off con-

trol can provide. Proportional control provides closer

control by adjusting the output when the temperature

or process value is within a proportional band. When

the value is in the band, the controller adjusts the

output based on how close the process value is to the

set point.

The closer the process value is to the set point, the

lower the output power. This is similar to backing

off on the gas pedal of a car as you approach a stop

sign. It keeps the temperature or process value from

swinging as widely as it would with simple on-off

control. However, when the system settles down, the

temperature or process value tends to “droop” short

of the set point.

With proportional control the output power level

equals (set point minus process value) divided by the

proportional band value.

In an application with one output assigned to

heating and another assigned to cooling, each will

have a separate proportional parameter. The heating

parameter takes effect when the process temperature

is lower than the set point, and the cooling param-

eter takes effect when the process temperature is

higher than the set point.

Adjust the proportional band with Heat Pro-

portional Band [`h;Pb] or Cool Proportional Band

[`C;Pb]

(Operations Page, Loop Menu).

Time

Temperature

Proportional Control

Set Point

Proportional Band

Droop

Overshoot

Proportional plus Integral (PI) Control

The droop caused by proportional control can be cor-

rected by adding integral (reset) control. When the

system settles down, the integral value is tuned

to bring the temperature or process value closer to

the set point. Integral determines the speed of the

correction, but this may increase the overshoot at

startup or when the set point is changed. Too much

integral action will make the system unstable. Adjust

the integral with Time Integral [``ti] (Operations

Page, Loop Menu).

Proportional, Integral and Derivative (PID) Control

Use derivative (rate) control to minimize the over-

shoot in a PI-controlled system. Derivative (rate) ad-

justs the output based on the rate of change in the

temperature or process value. Too much derivative

(rate) will make the system sluggish.

Adjust the derivative with Time Derivative

[``td]

(Operations Page, Loop Menu).

Time

Temperature

PID Control

Set Point

Reduced Overshoot

Proportional Band

Proportional Band x 2

Heating Slows

Dead Band

In a PID application the dead bands above and below

the set point can save an application’s energy and

wear by maintaining process temperature within ac-

ceptable ranges. Use Dead Band to set an offset for

the proportional band. With a negative value both

the heating and cooling outputs are active when the

process value is near the set point. A positive value

prevents heating and cooling outputs from being on

at the same time.

Proportional action ceases when the process value

is within the dead band. Integral action continues to

bring the process temperature to the set point.

Time

Temperature

Positive Dead Band

Set Point

Heat Output Active

Cool Output Active

When the dead band value is zero, the heat-

ing output activates when the temperature drops be-

low the set point, and the cooling output switches on

when the temperature exceeds the set point.

Time

Temperature

Zero Dead Band

Set Point

Heat Output Active

Cool Output Active