Ballast requirements, 11maintenance schedule, Maintenance schedule – MacDon M155 Operators Manual User Manual

Page 398: 11 maintenance schedule

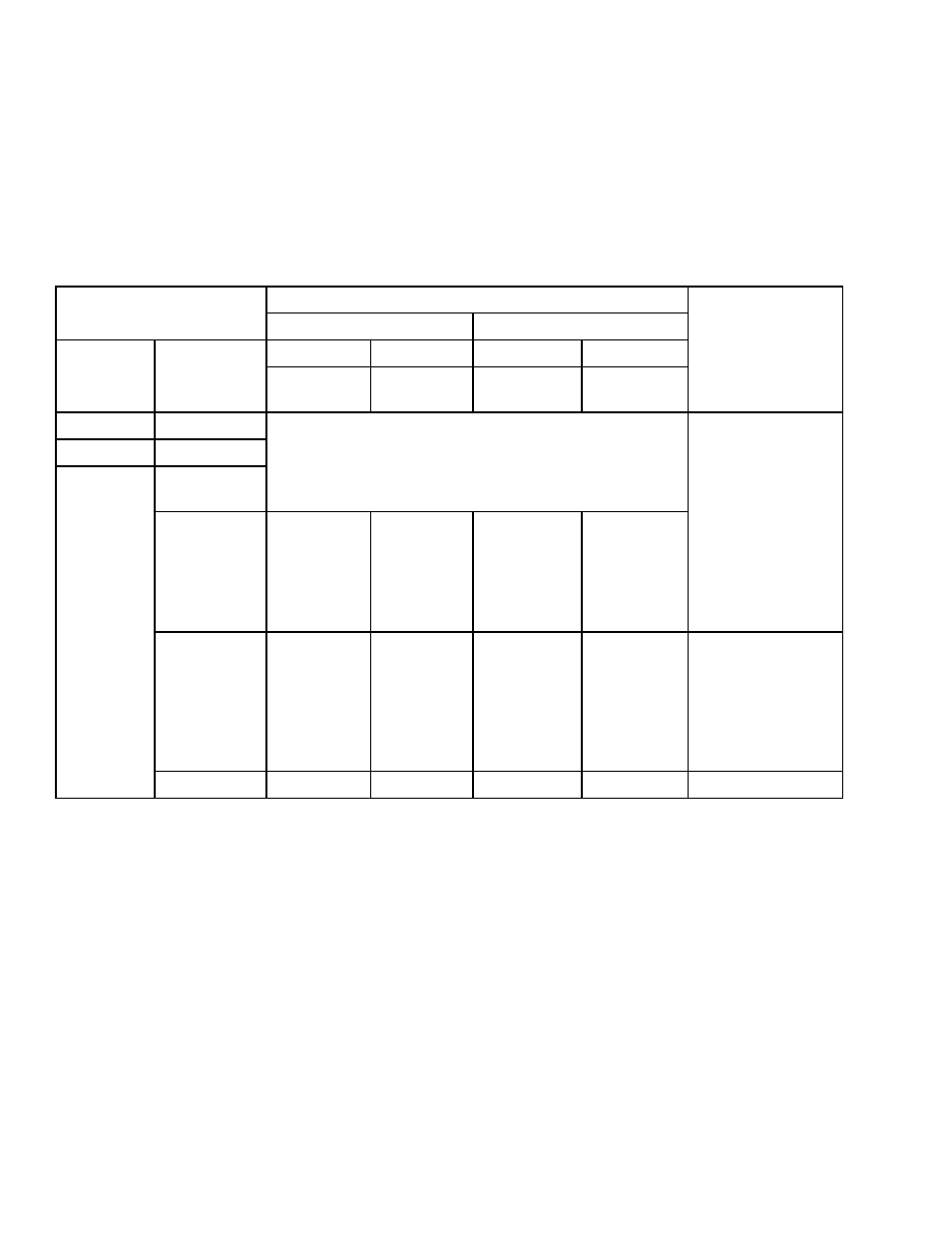

Ballast Requirements

Fluid ballasting of rear caster tires is recommended to provide adequate machine stability when using large

headers on the windrower. Also, the stability of the machine varies with different attachments, windrower options,

terrain, and the operator’s driving technique.

Ballast capability per tire is at a maximum fill of 75%, or when fluid is level with valve stem when the stem is positioned

at 12 o’clock. Fluid can be added to any level up to maximum fill. Always add an equal amount of fluid on both sides.

Recommended Ballast

Header Description

Level Ground

Hills

Per Tire

Both Tires

Per Tire

Both Tires

Type

Size

US Gal

(liters)

lb (kg)

US Gal

(liters)

lb (kg)

Recommended

Tire Size

A-Series

All options

R-Series

13 ft. ONLY

25-ft. and

down

0

30-ft. Single

or Double

Reel without

Conditioner.

35-ft. Single

Reel

0

0

10 (38)

200 (91)

7.5 X 16

10 X 16

16.5 X 16.1

30-ft. Double

Reel Steel

Fingers and

Conditioner.

35-ft.

Double Reel

(5 or 6-Bat)

18 (69)

380 (170)

30 (115)

630 (288)

Level Ground:

10 X 16

Level Ground:

16.5 X 16.1

Hills: 16.5 X 16.1

D-Series

40-ft

30 (115)

630 (288)

41 (158)

830 (377)

16.5 X 16.1

5.7.11

Maintenance Schedule

The Maintenance Schedule specifies the periodic maintenance procedures and service intervals.

Regular maintenance is the best insurance against early wear and untimely breakdowns. Following this schedule

will increase machine life.

For detailed instructions, refer to the various procedures in this chapter. Use the fluids and lubricants specified in

5.3.1 Recommended Fuel, Fluids, and Lubricants, page 262

Service Intervals: The recommended service intervals are in hours of operation. Where a service interval is given

in more than one time frame, for example, 100 hours or annually, service the machine at whichever interval is

reached first.

IMPORTANT:

Recommended intervals are for average conditions. Service the machine more often if operated

under adverse conditions (severe dust, extra heavy loads, etc.).

169883

382

Revision A