Flow control blocks, Adjusting header drop rate, Table 5.19 header hydraulic pressures – MacDon M155 Operators Manual User Manual

Page 382: 19 header hydraulic pressures, Danger

Table 5.19 Header Hydraulic Pressures

Header

Model

Application/System

Windrower Absolute

Pressure Limit Setting

psi (kPa)

Suggested Overload

Warning Setting

psi (kPa)

R-Series

Disc Pressure

4200 (28,958)

4000 (27,579)

Reel/Draper Pressure

3200 (22,063)

3000 (20,684)

D-Series

A-Series

Knife/Conditioner

Pressure

4200 (28,958)

4000 (27,579)

If lift and drive capacity problems develop, the pressure compensator valve may require adjusting. Contact your

MacDon Dealer or refer to the technical service manual for your windrower.

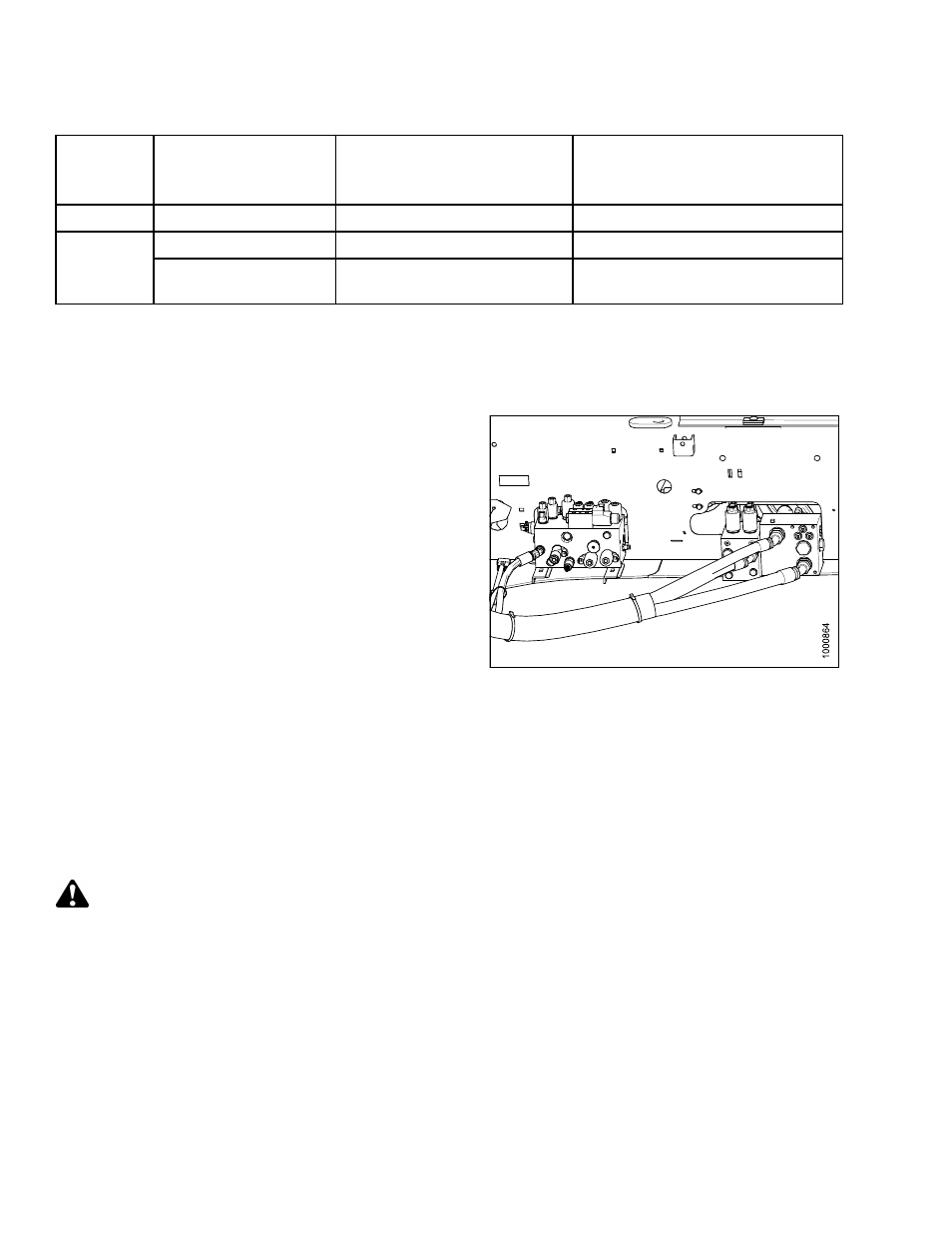

Flow Control Blocks

Two hydraulic valve blocks with multiple cartridges are

used for the various windrower functions and are controlled

by the windrower control module (WCM) according to the

inputs from the Operator. The valve blocks are located

behind the left cab-forward side platform.

The valve blocks do NOT require any scheduled

maintenance other than to check for leaking fittings or

loose electrical connections. If service is required, contact

your MacDon Dealer.

Figure 5.203: Hydraulic Valve Blocks

Adjusting Header Drop Rate

The header should lower gradually when the lower header switch is pressed. From full height to ground should

take approximately 3–4 seconds.

If drop rate is too slow, return to cut height or tilt or float presets may time out. This is to keep the hydraulics from

being pressurized.

DANGER

Stop engine and remove key from ignition before leaving operator's seat for any reason. A child or even a

pet could engage an idling machine.

1. Lower header to ground, stop the engine, and remove

the key.

2. Move left cab-forward side platform rearward. Refer

to

5.5.1 Opening Platforms (Standard Position), page

169883

366

Revision A