MacDon A Series Quick Card User Manual

MacDon Gardening equipment

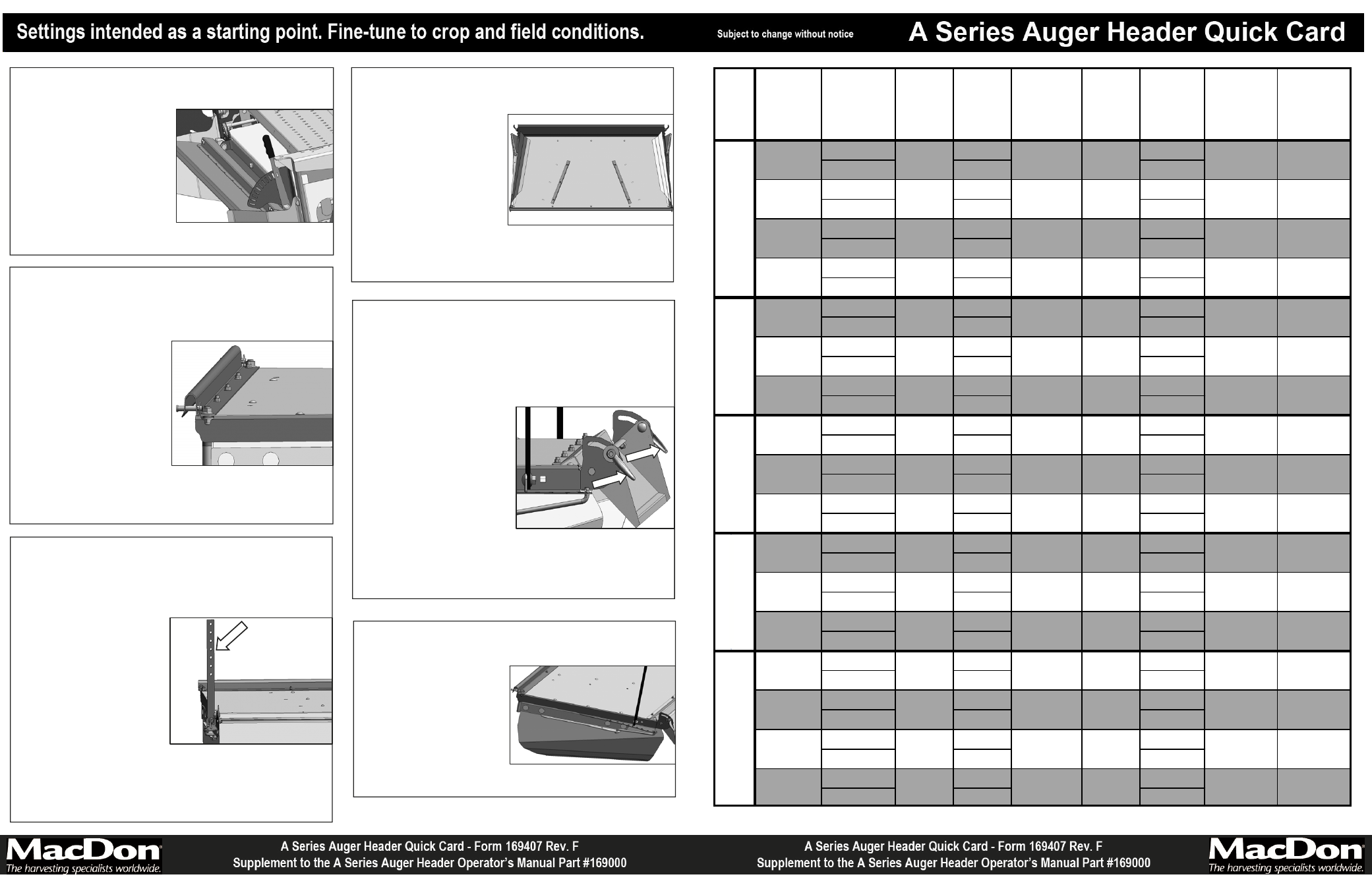

Smooth

7.0–8.0

70–80

Rocky

5.5–6.5

60–70

Smooth

7.0–8.0

70–80

Rocky

5.5–6.5

60–70

Smooth

8.0–8.5

75–85

Rocky

5.5–6.5

65–70

Smooth

7.5–8.5

80–90

Rocky

5.5–6.5

65–75

Smooth

7.0–8.0

70–80

Rocky

5.5–6.0

60–70

Smooth

7.0–8.0

70–80

Rocky

5.5–6.0

60–70

Smooth

7.0–8.5

80–90

Rocky

5.5–6.0

65–75

Smooth

7.0–8.0

70–80

Rocky

5.5–6.0

60–70

Smooth

7.0–8.0

70–80

Rocky

5.5–6.0

60–70

Smooth

7.5–8.5

80–90

Rocky

6.0–6.5

65–75

Smooth

7.0–8.0

70–80

Rocky

5.5–6.5

60–70

Smooth

7.5–8.5

75–85

Rocky

6.0–6.5

65–70

Smooth

7.5–8.5

80–90

Rocky

6.0–6.5

65–75

Smooth

7.5–8.0

70–80

Rocky

5.5–6.5

60–70

Smooth

7.5–8.0

70–80

Rocky

5.5–6.5

60–70

Smooth

7.5–8.5

75–85

Rocky

6.0–6.5

65–75

Smooth

7.5–8.5

80–90

Rocky

6.0–6.5

65–75

0 in.

0 in.

Lower Slot

Center Slot

Upper Slot

Variable

0 in.

0 in.

0 in.

0 in.

0 in.

1850–1950

1850–1950

1850–1950

1850–1950

73–77

70–75

65–70

73–77

1600–1800

60–65

Center Slot

1600–1800

70–75

65–70

70–75

70–75

Variable

Variable

70–75

Lower Slot

1700–1850

1600–1800

73–77

65–70

70–75

73–77

2–3 TPA

<2 TPA

Lodged

2.5–3 in.

2.5–3 in.

2.5–3 in.

6 in.

0 in.

Lodged

> 10 TPA

< 10 TPA

Lodged

> 3.5 TPA

< 2.5 TPA

Lodged

> 3 TPA

< 3 TPA

70–75

65–70

70–75

1850–1950

(w

in

te

r fo

ra

g

e)

> 3 TPA

2–3 TPA

< 2 TPA

Lodged

> 2.5 TPA

0 in.

0 in.

1600–1800

1600–1800

1600–1800

1600–1800

0 in.

6 in.

6 in.

1700–1850

1700–1850

1850–1950

1850–1950

1/2 in.

3/8 in.

see above

3/8 in.

1/4 in.

see above

3/4 in.

5/8 in.

Lower Slot

Center Slot

Upper Slot

Variable

Lower Slot

Center Slot

Variable

Lower Slot

Center Slot

Crop

Type

T

rit

ic

al

e

W

il

d

/G

ra

ss

H

ay

S

uda

n/

Ta

ll

C

rop

Ti

m

o

th

y

A

lf

al

fa

see above

1 inch

1 inch

see above

3/8 in.

1/4 in.

1/4 in.

see above

Crop

Condition

TPA

(tons

per acre)

Field

Condition

Header

Height

Header

Angle

Knife

Speed

Reel

RPM

Float

(LBS)

Feed Pan

Position

Roll Gap

5/8 in.

Windrow Width Adjustment

Center Baffle Position

For narrower windrows, the

center baffle is usually in

full up position.

Handle can be lowered 1 or

2 notches to prevent crop

from being projected above

the forming shield top

cover.

Position the center baffle all

the way down to obtain

maximum swath width.

Remove the hair pin that

secures the strap to the

windrower.

Lower or raise shield to

the desired height.

Re-insert the hair pin.

Generally, the fourth hole

from the top of the strap

(shown) provides a good

starting position for most

crops.

Lower rear of the forming

shield if the crop is not

hitting the top cover.

When using DWA, use

the highest forming shield

position.

Forming Shield Rear Height Adjustment

Inner Deflecting Fins

Fins are bolted underneath

the forming shield.

Fins aid in distributing crop

material evenly throughout

the windrow.

Removing or adding fins

will change crop flow. Each

fin can be mounted in three

alternative positions.

Position fins to obtain even

crop distribution across full

width of the windrow/swath.

Remove the lynch pin.

Move arm into the desired

position. Re-insert the

lynch pin.

For narrow windrow, use

holes closest to the header.

For wider windrow, use

holes furthest away from

the header.

Mount forming shield front

support bolt in the upper

hole in the tractor lift

linkage.

For smoother windrows in

lighter crops, the lower

hole in the lift linkage may

be used so that the crop

flow engages the forming

shield closer to the front

edge.

When using the DWA

attachment, the front of the

forming shield must be

mounted to the upper hole

in the lift linkage.

Forming Shield Front Mounting Point

Rear Baffle Fluffer Adjustment

Loosen handle (shown), and

raise or lower baffle to

adjust the angle.

Tighten handle to lock its

position (NOTE: This must

be done on both sides).

A greater angle (i.e., baffle

pointed down) will allow for

“fluffy” windrows.

An excessively steep baffle

angle may cause an uneven

windrow.

When using DWA, position

the rear baffle in the highest

position. (NOTE: It may be

necessary to lower the LH

side to direct crop onto the

DWA belt).