Removing drive wheel, Installing drive wheel, Caution – MacDon M155 Operators Manual User Manual

Page 391

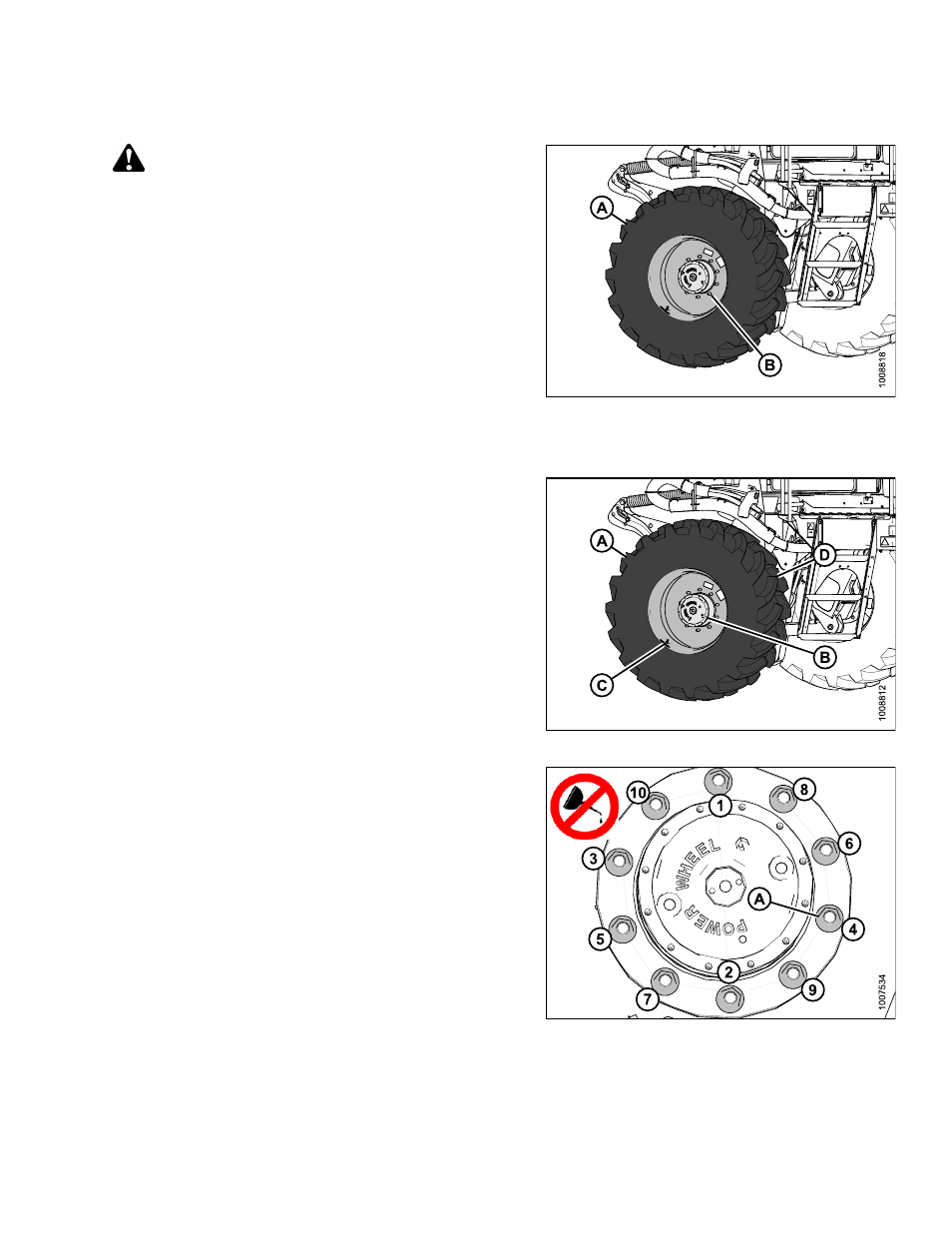

Removing Drive Wheel

CAUTION

Use a suitable lifting device capable of supporting

a minimum of 2000 lbs (907 kg) to lift the wheel

assembly away from the windrower.

1. Raise the windrower drive wheel (A) off the ground.

Refer to

2. Remove the wheel nuts (B).

3. Remove the drive wheel (A).

Figure 5.216: Drive Wheel Assembly

Installing Drive Wheel

NOTE:

Windrower must be supported off the ground with

stands. Refer to

1. Position drive wheel (A) against wheel drive hub (B), so

that air valve (C) are on the outside and tire tread (D)

points forward, when windrower is in cab forward.

For Turf tires (diamond tread), be sure arrow on

sidewall points in forward rotation, when windrower in

cab forward.

2. Lift wheel on hub with lifting device.

Lower

lifting device.

Figure 5.217: Drive Wheel Assembly

3. Line up the holes in the rim with the studs on the wheel

drive hub and install wheel nuts (A).

NOTE: To avoid damage to wheel rims and studs, tighten

nuts by hand, do NOT use an impact gun, do NOT

use lubricant or Never-Seez

®

compound, and do

NOT

overtighten wheel nuts.

4. Torque drive wheel nuts. Refer to

.

5. Lower the windrower, and remove jack.

Refer to

Lowering Drive Wheel, page 376

.

6. After one hour of operation, retorque the wheel nuts.

Then check every hour until two consecutive checks

produce no movement of the nuts.

Figure 5.218: Drive Wheel Nuts

169883

375

Revision A