Adjusting screen cleaner duct to screen clearance, Maintenance and servicing – MacDon M155 Operators Manual User Manual

Page 336

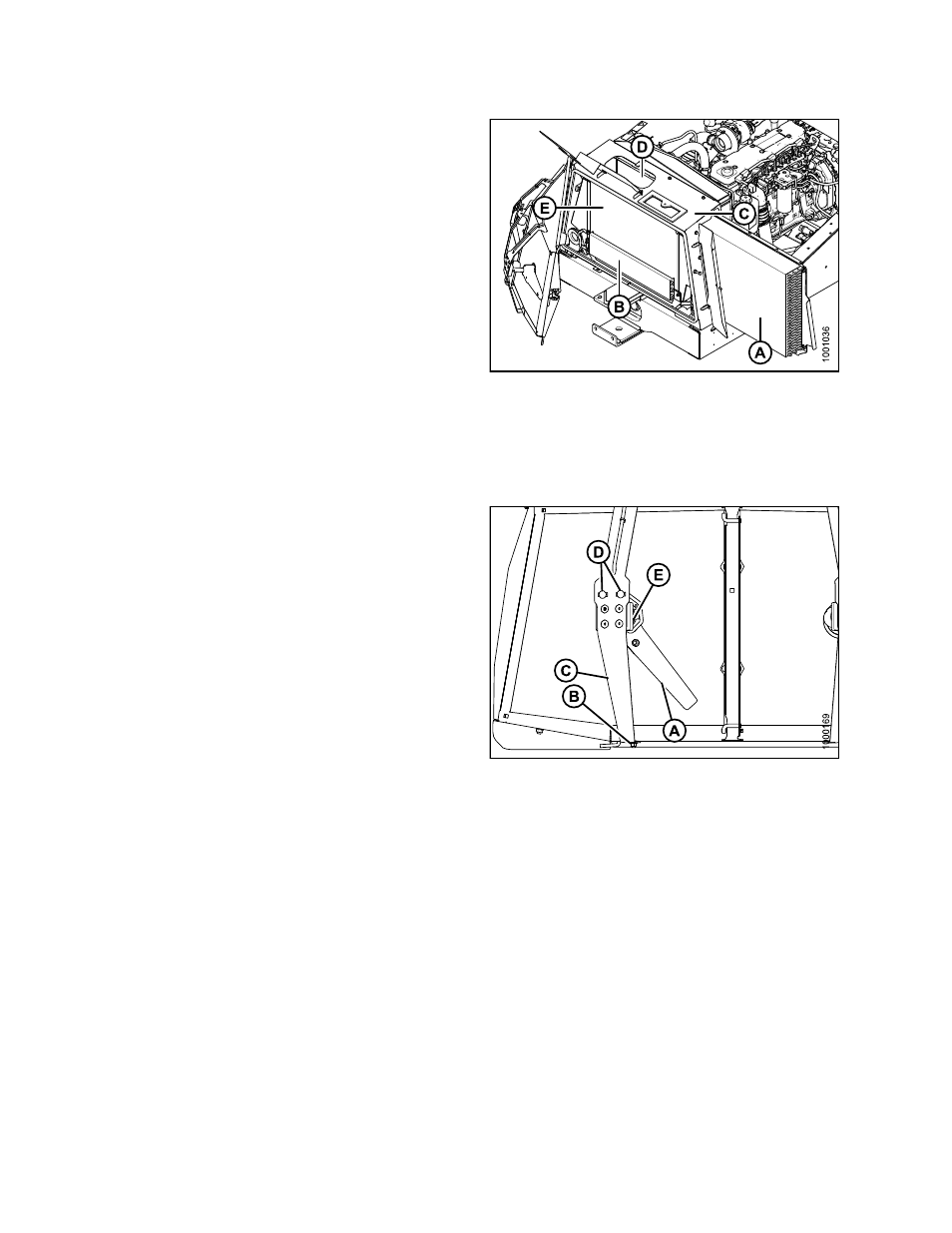

6. Clean radiator (D) through access holes in cooling box

with compressed air.

7. Clean oil cooler / air conditioning condenser (A),

charge air cooler (E), fuel cooler (B), and cooling

box (C) with compressed air.

8. Inspect all lines and coolers for evidence of leaks

and damage.

9. Slide oil cooler / air conditioning condenser (A) back

into cooling box (C).

10. Close side access door and lock with lever.

11. Close access door on top of the cooling box and secure

with wing nut.

12. Close cooler box screen. Refer to

Figure 5.114: Engine Cooling System

A - Oil Cooler/Condenser

B - Fuel Cooler

C - Cooling Box

D - Radiator

E - Air Cooler

Adjusting Screen Cleaner Duct to Screen Clearance

Check clearance between trailing edge of screen cleaner

duct (A) and screen. It should be 3/64–5/16 in. (1–8 mm)

at all locations when rotating.

NOTE:

Screen cleaner ducts rotate counterclockwise and

may touch screen as long as it continues to rotate.

If necessary, adjust clearance as follows:

1. Open the hood. Refer to

2. Loosen nut (B) on motor support (C).

3. Move support in or out until duct is 3/32–1/4 in.

(2–6 mm) from screen near the center.

4. Retighten nut (B).

5. Loosen the two motor mount bolts (D).

6. Move motor/duct assembly (E) to obtain 3/64–5/16 in.

(1–8 mm) gap to screen at full rotation of the duct.

7. Retighten nuts (D) on motor mount.

8. Close the hood. Refer to

Figure 5.115: Engine Cooling System

169883

320

Revision A