Header and reel hydraulics, Pressure compensator valve – MacDon M155 Operators Manual User Manual

Page 381

NOTE:

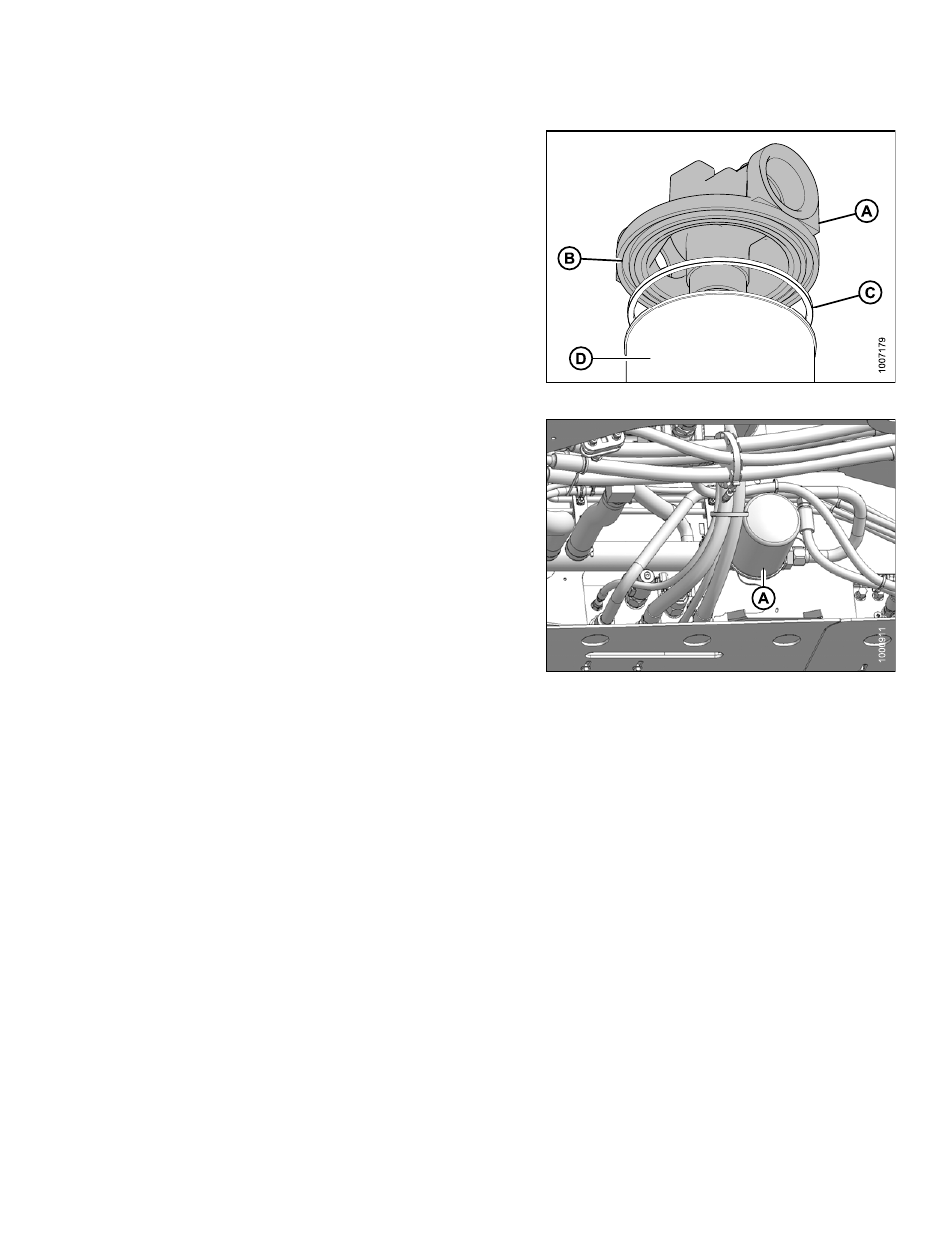

Image showing filter head removed to show

component clarity.

1. Clean the gasket groove (B) in the filter head (A).

2. Apply a thin film of clean oil to the filter gasket (C).

3. Install new gasket into the groove (B) in the filter

head (A).

4. Screw the new filter (D) onto the filter head until the

gasket contacts the filter.

Figure 5.201: Hydraulic System

5. Tighten filter an additional 3/4 turn by hand.

IMPORTANT:

Do NOT use a filter wrench to install oil filter.

Overtightening can damage gasket and filter.

6. Check hydraulic fluid levels. Refer to

Filling Hydraulic Oil, page 360

. For capacity level, refer

to

Lubricants, Fluids, and System Capacities, page

.

Figure 5.202: Hydraulic System

Header and Reel Hydraulics

Pressure Compensator Valve

The pressure compensator valve protects the header drive pumps from overheating under very heavy loads.

When the operating pressure reaches the absolute pressure limit setting (refer to

5.19 Header Hydraulic Pressures,

) the compensator valve in the pump is activated and the header drive will slow down to avoid overheating

the drive pumps. At this point, reduce the ground speed to maintain the correct system load and header drive

operation.

NOTE:

An optional pressure sensor is available to monitor the knife or reel drive hydraulic pressure and

provide a warning tone from the cab display module (CDM) if the system pressure approaches a

preset limit. The system pressure limit is set during CDM programming. Refer to

.

.

NOTE:

The warning tone is only heard if the pressure sensor is installed and enabled.

NOTE: A warning tone is normal when the operating pressure is close to the compensator valve’s pressure

setting.

169883

365

Revision A