Application example - generation of feed profiles, Application example − generation of feed profiles, Commissioning – Lenze EVS9332xK User Manual

Page 215

Commissioning

Generation of motion profiles

Application example − generation of feed profiles

6.10

6.10.7

l

6.10−7

EDSVS9332K EN 8.0−07/2013

1

2

3

9300kur073

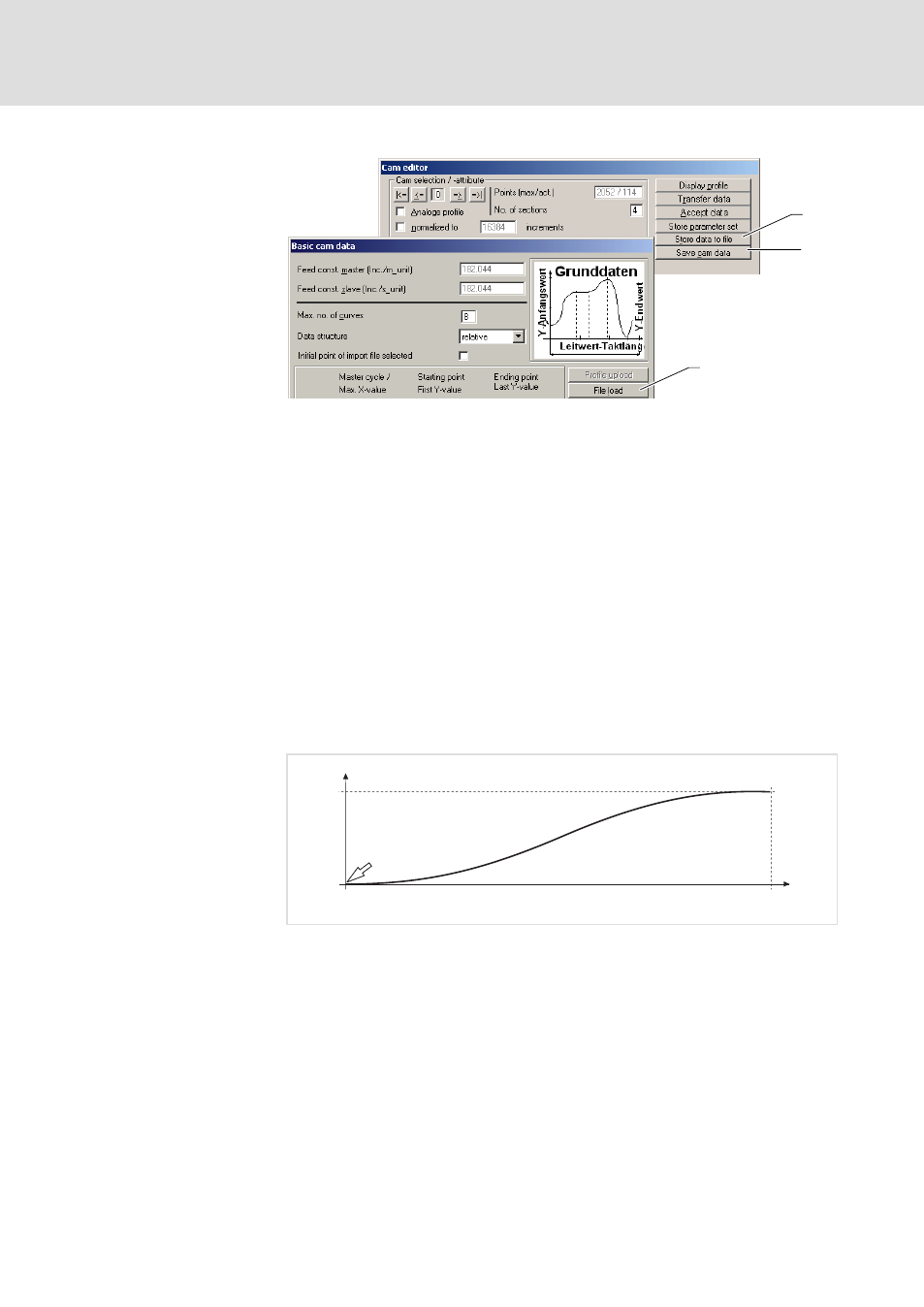

Fig. 6.10−6

Dialog boxes "Cam editor" and "Basic cam data"

ƒ Saving the motion profile for the transfer from the PLC/IPC to the

controller

Click on the "Save cam data" button (2) to save the motion profile in an

LC7 file.

– The profile data is saved in 64−bit format.

ƒ Saving the motion profile independently of the parameter set in a file

Click on the "Store data to file" button (1) to save the motion profile in an

LCD file.

To reload a saved motion profile to the parameter set, click on the "File

load" button (3).

6.10.7

Application example − generation of feed profiles

0

0

180

y

360

s_units

m_units

x

1

9300kur058

Fig. 6.10−7

Profile characteristic for a feed movement

To avoid jolts of the drive, do not start the motion profile with a starting

point y

0

¹ 0. To ensure this, do not change the default value "0" of the profile

in the "Starting point: First Y−value" column.

The factory−set motion profiles always start with x

0

= 0 / y

0

= 0 (see arrow).

External saving of the motion

profile in the profile editor

Generation of a motion

profile consisting of a single

profile