Handwheel function, Commissioning – Lenze EVS9332xK User Manual

Page 237

Commissioning

Handwheel function

6.15

l

6.15−1

EDSVS9332K EN 8.0−07/2013

6.15

Handwheel function

The handwheel function facilitates set−up and commissioning of the

system.

To avoid damage of the machine, the line shaft is moved slowly by hand

during the set−up process, while the operator checks the interaction of the

axes coupled via the line shaft.

HMI

0

1

2

3

3

4

9300kur067

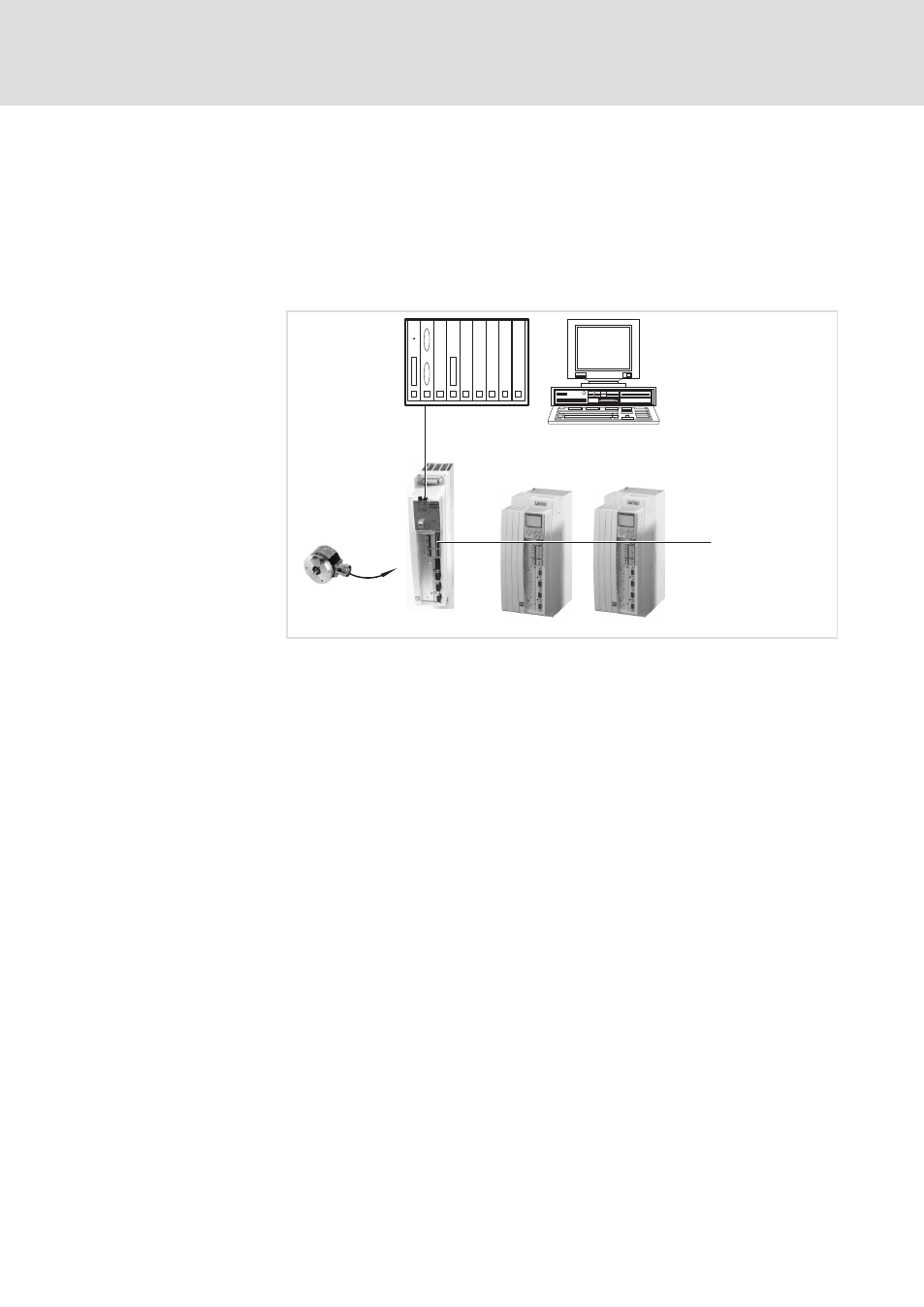

Fig. 6.15−1

Handwheel function of 9300 servo cam profiler

0 PLC/IPC

1 Fieldbus

2 Virtual master

3 Slave

4 System bus (CAN)

Handwheel function of the electronic cam:

ƒ To X9 of the master, a simple incremental encoder is connected as a

handwheel.

ƒ In order to process the incremental encoder signals, function blocks

have to be interconnected in the master (see Fig. 6.15−2).

– It may be necessary to adapt the interconnection to your application.

ƒ The handwheel determines the angle of rotation for master and slaves

( line shaft").

ƒ The cams similarly follow the rotation speed and direction of the

handwheel.

ƒ The 9300 servo cam profiler can be easily and quickly optimised for

your application.