6 counters, 1 ctu, 2 ctd – Lenze DDS v2.3 User Manual

Page 306: Drive plc developer studio

Drive PLC Developer Studio

IEC 61131-3 Standard functions

14-14

l

DDS EN 2.3

14.6

Counters

14.6.1

CTU

Up counter

CU

, RESET and Q are of type BOOL, PV and CV are of type INT.

•

If RESET is TRUE, the counter variable CV is set to 0.

•

Every positive edge at input

CU increases CV by 1.

As long as

CV is less than PV max (i.e. no overflow).

•

Q

returns TRUE if CV is greater than or equal to the upper limit PV .

CTU(CU, RESET, PV, Q, CV)

means:

•

If RESET is TRUE, the counter variable CV will be initialized with 0.

•

If CU has a rising edge, CV will be increased by 1.

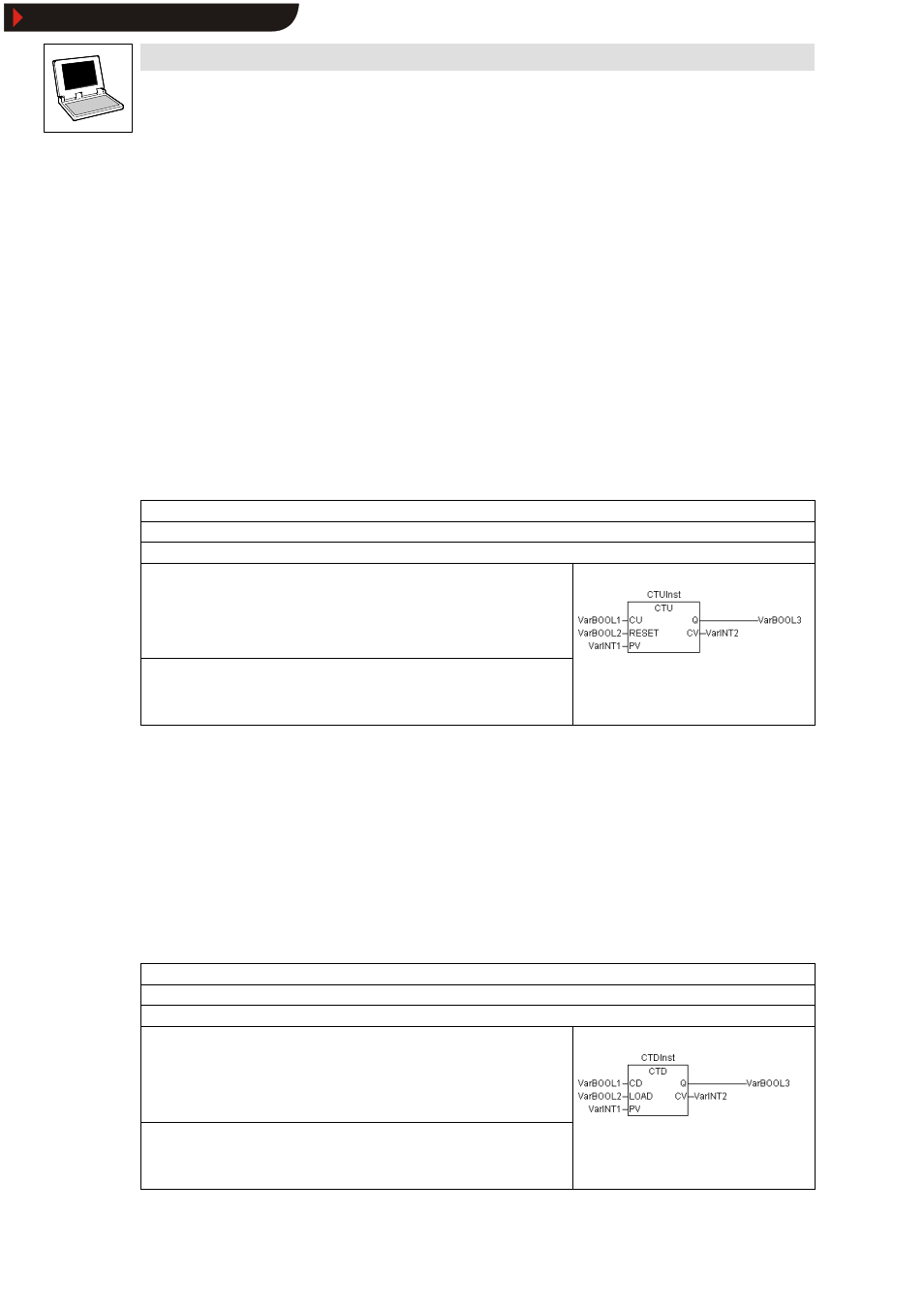

Examples

Declaration:

CTUInst : CTU;

IL

FBD

CAL CTUInst(CU:=VarBOOL1, RESET:=VarBOOL2, PV:=VarINT1)

LD CTUInst.Q

ST VarBOOL3

LD CTUInst.CV

ST VarINT2

ST

CTUInst(CU:=VarBOOL1, RESET:=VarBOOL2, PV:=VarINT1);

VarBOOL3:=CTUInst.Q;

VarINT2:=CTUInst.CV;

14.6.2

CTD

Down counter

CD

, LOAD and Q are of type BOOL, PV and CV are of type INT.

•

If LOAD is TRUE, the counter variable CV will be set equal to the upper limit PV.

•

If LOAD is FALSE, every function block call will decrease CV by 1.

•

Q

returns TRUE if CV is less than or equal to 0.

CTD(CD, LOAD, PV, Q, CV)

Examples

Declaration:

CTDInst : CTD;

IL

FBD

CAL CTDInst(CD:=VarBOOL1, LOAD:=VarBOOL2, PV:=VarINT1)

LD CTDInst.Q

ST VarBOOL3

LD CTDInst.CV

ST VarINT2

ST

CTUInst(CD:=VarBOOL1, LOAD:=VarBOOL2, PV:=VarINT1);

VarBOOL3:=CTDInst.Q;

VarINT2:=CTDInst.CV;

Show/Hide Bookmarks