INFICON XTC/3 Thin Film Deposition Controller Operating Manual User Manual

Page 144

5 - 32

PN

07

4-

44

6-

P1

J

XTC/3 Operating Manual

14

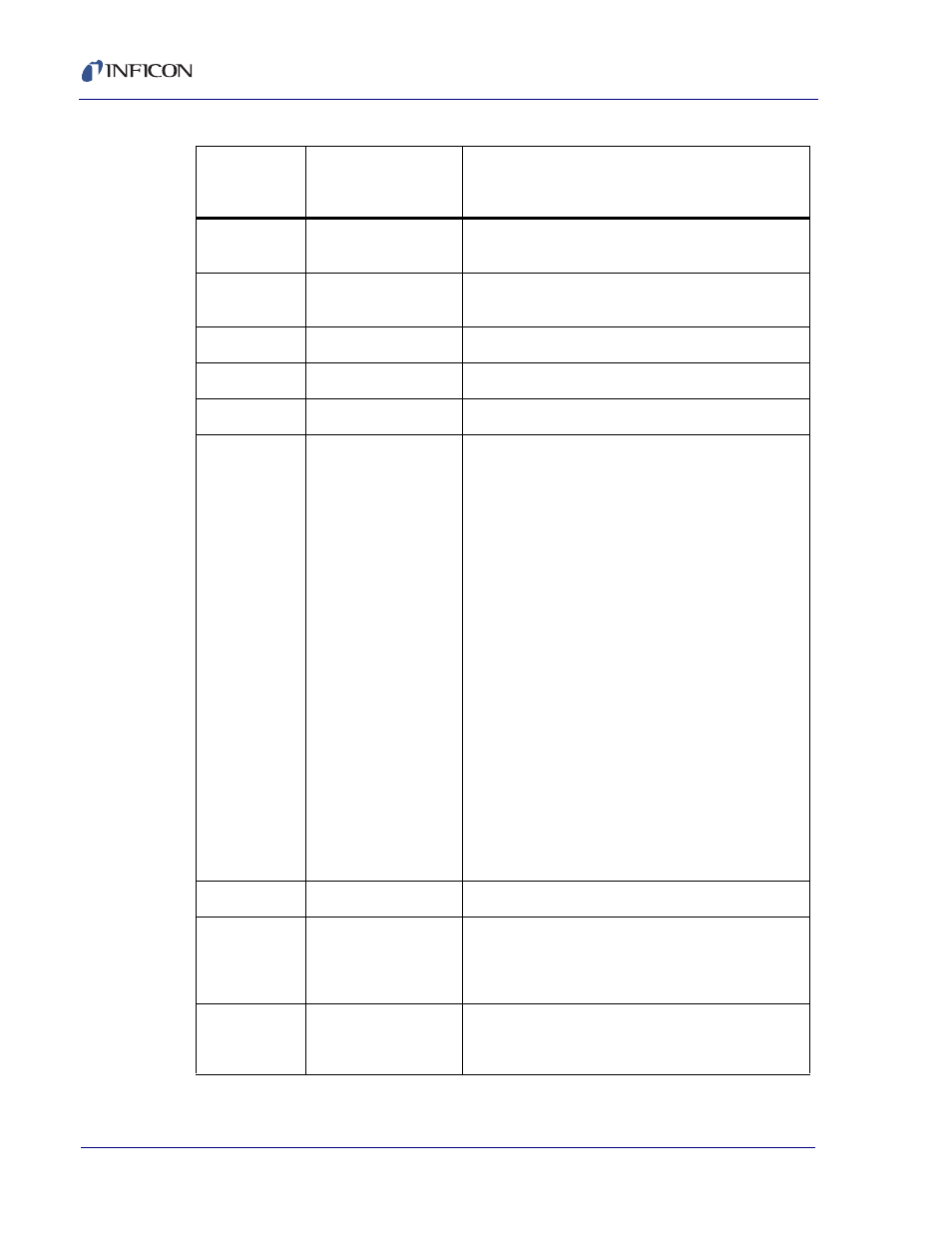

(0x0e)

Xtal Fail

(Byte) 0 = good crystal / not in Xtal Fail;

1 = failed crystal / in Xtal Fail

15

(0x0f)

Max Power

(Byte) 0 = false not in max power;

1 = true in max power

16 (0x10)

Crystal Switching

(Byte) 0 = not switching; 1 = switching

17 (0x11)

End of process

(Byte) 0 = False; 1 = True

18 (0x12)

Stop

(Byte) 0 = False; 1 = True

19

(0x13)

Data Log

Returns data as follows

Layer # (Int)

Film # (Int)

Rate (Float) Å/Sec - One second average-

Thickness (Float) kÅ

Deposit time (Int) Seconds

Average power (Float) %

S Value (Int)

Q Value (Byte)

Begin Frequency (Float) HZ

End Frequency (Float) HZ

Crystal Life (Byte) %

Layer end type (Byte) -Normal end (0), Time power

end (1) or Stop (2) -

Cause of stop: (Byte)

0 = No stop

1 = Keyboard

5 = Crystal Fail

6 = Max Power

7 = Hand Controller

8 = Communications

9 = Digital Input

10 = Power Loss

11 = Rate Dev Error

12 = Crystal Switcher fail

20 (0x14)

Active Process

(Byte)

21 (0x15)

Power up error flag

(Byte) Bit is set indicating error as follows:

0 = Parameter loss on power cycle

1 = Process variables loss on power cycle

2 = Power down/up cycle

30

(0x1e)

Crystal Status

(2 Bytes) Each bit indicates one crystal of a multi-head

sensor. 1 = Good Crystal, 0 = Failed Crystal. LSB is

Crystal 1. All bits > number of crystals on sensor are 0.

Table 5-4 Standard Status commands (continued)

S

(0x53)

Command ID

Description

Response:

Description (Data Format) Units -Detail-