3 installing the sk 2xxe – NORD Drivesystems BU0200 User Manual

Page 26

2 Assembly and installation

BU 0200 GB-4411

Subject to technical alterations

25

2.1.3

Installing the SK 2xxE

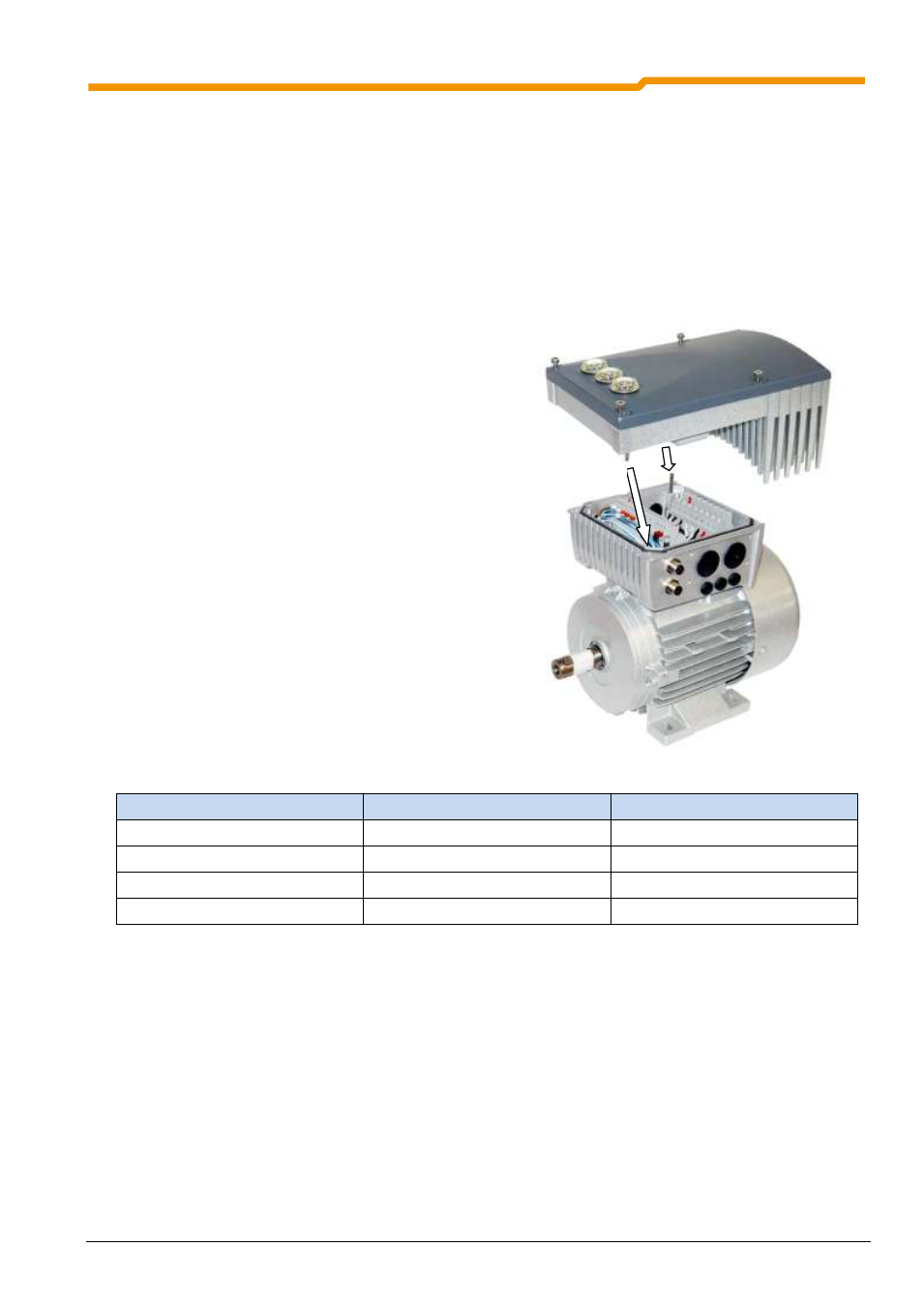

In order to make the electrical connections to the SK 2xxE it may first be necessary to remove it from the

connection unit. To do this, remove the 4 fastening screws, so that the frequency inverter can be lifted off

vertically.

After the electrical connection of the power cables has been made, the frequency inverter can be replaced.

This must be carried out in a vertical direction relative to the connection unit without tilting. The PE cinch

plug can be used in order to ensure correct guidance.

In order to achieve the maximum protection class

IP55/IP66, care must be taken that all frequency

inverter fixing screws are gradually tightened

diametrically oppositely, with the torques stated in

the table below.

For the cable gland of the connecting cable,

appropriate screwed connections for cable cross-

section must be used.

Up to size 3 dissipation of the frequency inverter

heat loss is by convection. This is assisted by the

airflow of the motor. Because of this, a reduction in

power for unventilated motors or wall-mounted

devices must be taken into account (for further

details see Section 8, Technical Data).

Heat dissipation must not be hindered by severe

contamination.

Size 4 frequency inverters dissipate their heat loss

via an integrated fan.

Frequency inverter size

Screw size

Tightening torque

Size 1

M5 x 45

3.5Nm ± 20%

Size 2

M5 x 45

3.5Nm ± 20%

Size 3

M5 x 45

3.5Nm ± 20%

Size 4

M8 x 20

5,0Nm ± 20%

Cinch plug