NORD Drivesystems BU0200 User Manual

Page 203

SK 200E Manual for frequency inverters

202

Subject to technical alterations

BU 0200 GB-4411

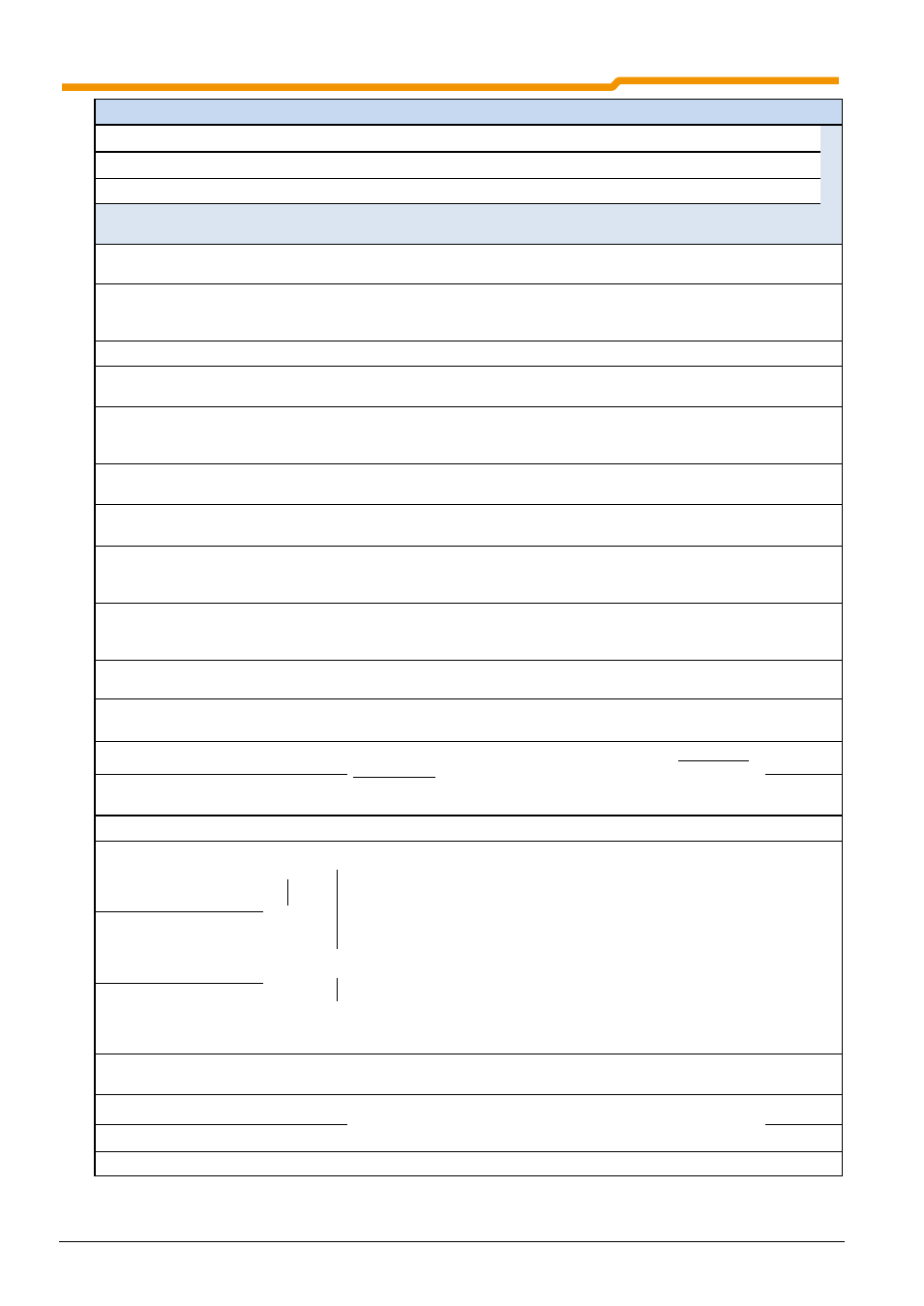

Value Function

Description

Signal

05

1

Fixed frequency 2

The frequency from P465 [02] is added to the actual setpoint value.

High

06

1

Fixed frequency 3

The frequency from P465 [03] is added to the actual setpoint value.

High

07

1

Fixed frequency 4

The frequency from P465 [04] is added to the actual setpoint value.

High

If several fixed frequencies are actuated simultaneously, then they are added with the correct sign. In addition,

the analog setpoint (P400) and if required, the minimum frequency (P104) are added.

08

Param set switching

"Parameter set switchover 1"

Selection of the active parameter set 1…4 (P100)

High

09

Maintain the freq

"Maintain the frequency"

During the acceleration or deceleration phase, a Low level will

cause the actual output frequency to be "held". A High level allows

the ramp to proceed.

Low

10

2

Voltage disable

The FI output voltage is switched off; the motor runs down freely.

Low

11

2

Quick stop

The FI reduces the frequency according to the programmed quick

stop time (P426).

Low

12

2

Fault acknowledgem

"Fault acknowledgement"

Error acknowledgement with an external signal. If this function is

not programmed, a fault can also be acknowledged by a low

enable setting (P506).

0

1

Flank

13

2

PTC resistor input

Only with the use of a temperature monitor (bimetal switching

contact). Switch-off delay = 2sec, warning after 1 sec.

High

14

2

Remote control

With bus system control, low level switches the control to control

via control terminals.

High

15

Jog frequency

1

The fixed frequency value can be adjusted using the

HIGHER/LOWER and OK keys (P113), if control is via the

SimpleBox or ParameterBox.

High

16

Motor potentiometer

As in setting 09, however, the frequency is not maintained below

the minimum frequency P104 and above the maximum frequency

P105.

Low

17

ParaSetSwitching 2

"Parameter set switchover 2"

Selection of the active parameter set 1…4 (P100)

High

18

2

Watchdog

Input must see a high flank cyclically (P460), otherwise error E012

will cause a shutdown. Function starts with the 1st High flank.

0

1

Flank

19

Setpoint 1 on/off

Analog input switch-on and switch-off 1/2 (high = ON) of the first

I/O extension. The low signal sets the analog input to 0% which

does not lead to shutdown when the minimum frequency (P104) >

than the absolute minimum frequency (P505).

High

20

Setpoint 2 on/off

High

21

...25 reserved for Posicon

26

Analog function

Dig2+3

("0-10V")

Th

e

s

e

f

u

n

c

ti

o

n

s

c

a

n

o

n

ly

be

u

s

e

d

f

o

r t

h

e

d

ig

it

a

l

in

p

u

ts

2

(P4

2

0

[

-0

2

])

a

n

d

3

(P4

2

0

[

-0

3

])

and

n

o

t

wit

h

SK

2

x

0

E

S 4

!

Via DIN 2 and DIN 3impulses which are proportional to an analog

signal can be evaluated with this setting. The function of this

signal is determined in parameter P400

[-06] or [-07].

The conversion 0-10V to impulses can be carried out via the

Customer Unit SK CU/TU4-24V-... This module includes an

analog input and an impulse output (ADC).

In setting { 28 } a reversal of the direction of rotation takes place

with an analog value <5V.

An application example is described in Section 3.4.2.

Impulses

≈ 1.6-

16kHz

27

Analog function

2-10V Dig2+3

28

Analog function

5-10V Dig2+3

30

Inhibit PID

Switching the PID controller / process controller function on and

off (High = ON)

High

31

2

Inhibit turn right

Blocks the >Enable right/left< via a digital input or Bus control.

Does not depend on the actual direction of rotation of the motor

(e.g. following negated setpoint).

Low

32

2

Inhibit turn left

Low

33

... 44 reserved

...continued on the next page