NORD Drivesystems BU0200 User Manual

Page 221

SK 200E Manual for frequency inverters

220

Subject to technical alterations

BU 0200 GB-4411

Parameter

{Factory setting}

Setting value / Description / Note

Device

Supervisor

Parameter

set

P533

Factor I

2

t Motor

(Factor I

2

t-Motor)

S

50 ... 150 %

{ 100 }

The motor current for the I

2

t motor monitoring P535 can be weighted with the parameter P533.

Larger factors permit larger currents.

P534

[-01]

[-02]

Torque disconn. limit

(Torque disconnection limit)

S

P

25 ... 400 % / 401

{ all 401 }

Via this parameter both the drive [-01] and the generator switch-off value [-02] can be

adjusted.

If 80% of the set value is reached, a warning status is set. At 100% switch-off is performed with

an error message.

Error 12.1 is given on exceeding the motor switch-off limit and E12.2 on exceeding the

generator switch-off limit.

[-01] = motor switch-off limit

[-02] = generator switch-off limit

401 = OFF, means that this function has been disabled.

P535

I

2

t motor

(I

2

t motor)

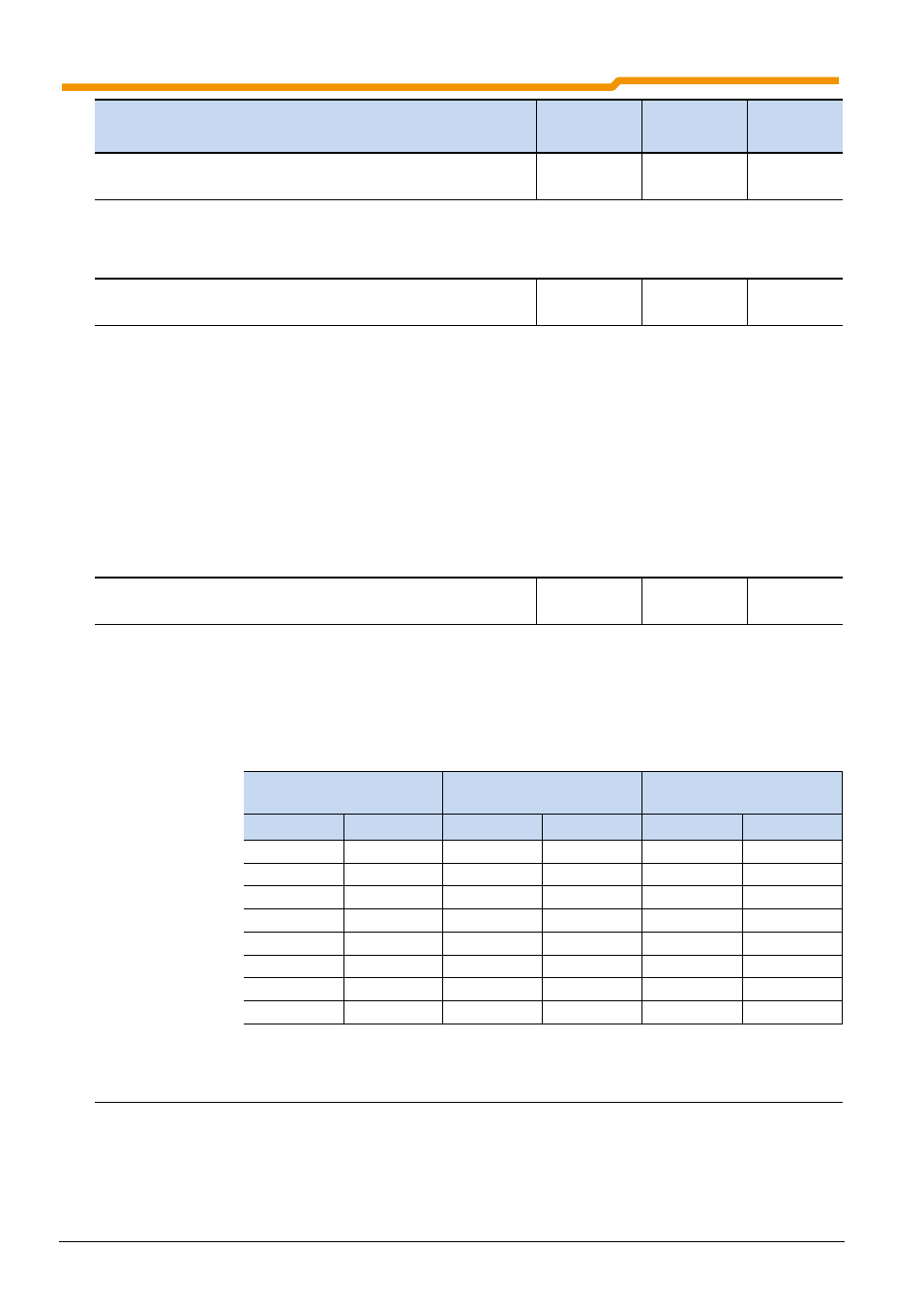

0 … 24

{ 0 }

The I

2

t motor function can now be set in a differentiated manner. Up to four curves with three

different triggering times can be set. The trigger times are based on classes 5, 10 and 20 for

semiconductor switching devices.

All curves run from 0Hz to half of the nominal motor frequency (P201). The full nominal current

is available from half of the nominal frequency upwards.

0 = I

2

t Motor Off: Monitoring is inactive

Switch-off class 5,

60s at 1.5x I

N

Switch-off class 10,

120s at 1.5x I

N

Switch-off class 20,

240s at 1.5x I

N

I

N

at 0Hz

P535 =

I

N

at 0Hz

P535 =

I

N

at 0Hz

P535 =

100%

1

100%

9

100%

17

90%

2

90%

10

90%

18

80%

3

80%

11

80%

19

70%

4

70%

12

70%

20

60%

5

60%

13

60%

21

50%

6

50%

14

50%

22

40%

7

40%

15

40%

23

30%

8

30%

16

30%

24

NOTE:

For switch-off classes 10 and 20, care must be taken that the FI has a sufficiently

high overload capacity.