Program examples – IAI America XSEL-KX User Manual

Page 290

274

Part 4 Commands

5. Program Examples

(1) Program example using PAPS (set by 3-point teaching)

The example below specifies movement only and does not cover picking operation.

Step

E

N

Cnd

Cmnd

Operand 1

Operand 2

Pst

Comment

1

VELS

80

PTP travel speed: 80%

2

ACCS

50

PTP travel acceleration: 50%

3

DCLS

50

PTP travel deceleration: 50%

4

VEL

100

CP travel speed: 100 mm/sec

5

ACC

0.3

CP travel acceleration: 0.3 G

6

DCL

0.3

CP travel deceleration: 0.3 G

7

SLWK

0

Select load coordinate system No. 0.

8

SLTL

0

Select tool coordinate system No. 0.

9

10

BGPA

1

Start setting palletizing No. 1.

11

PAPI

5

7

Palletizing counts: 5 x 7

12

PAPS

101

Set by 3-point teaching.

13

PEXT

104

Set palletizing R-axis coordinate.

14

PSLI

20

4

Zigzag offset = 20 mm

15

PAPN

1

Palletizing pattern 1

16

PCHZ

3

Palletizing Z-axis = Axis 3

17

PTRG

105

105

Set palletizing arch triggers.

18

OFPZ

5

PZ-axis offset = 5 mm

19

EDPA

20

21

ATRG

105

105

Set arch triggers.

22

ACHZ

3

Arch-motion Z-axis = Axis 3

23

24

PTPL

Perform positioning in PTP mode using left arm.

25

MOVP

110

Move to picking position in PTP mode.

26

PSET

1

1

Set palletizing position number to 1.

27

TAG

1

Beginning of loop processing

28

PACH

1

106

Palletizing arch motion

29

ARCH

110

106

Arch motion

30

PINC

1

600

Increment palletizing position number by 1.

31

600

GOTO

1

Beginning of loop when PINC is successful.

32

MOVL

109

Move to standby position in CP mode.

33

EXIT

End

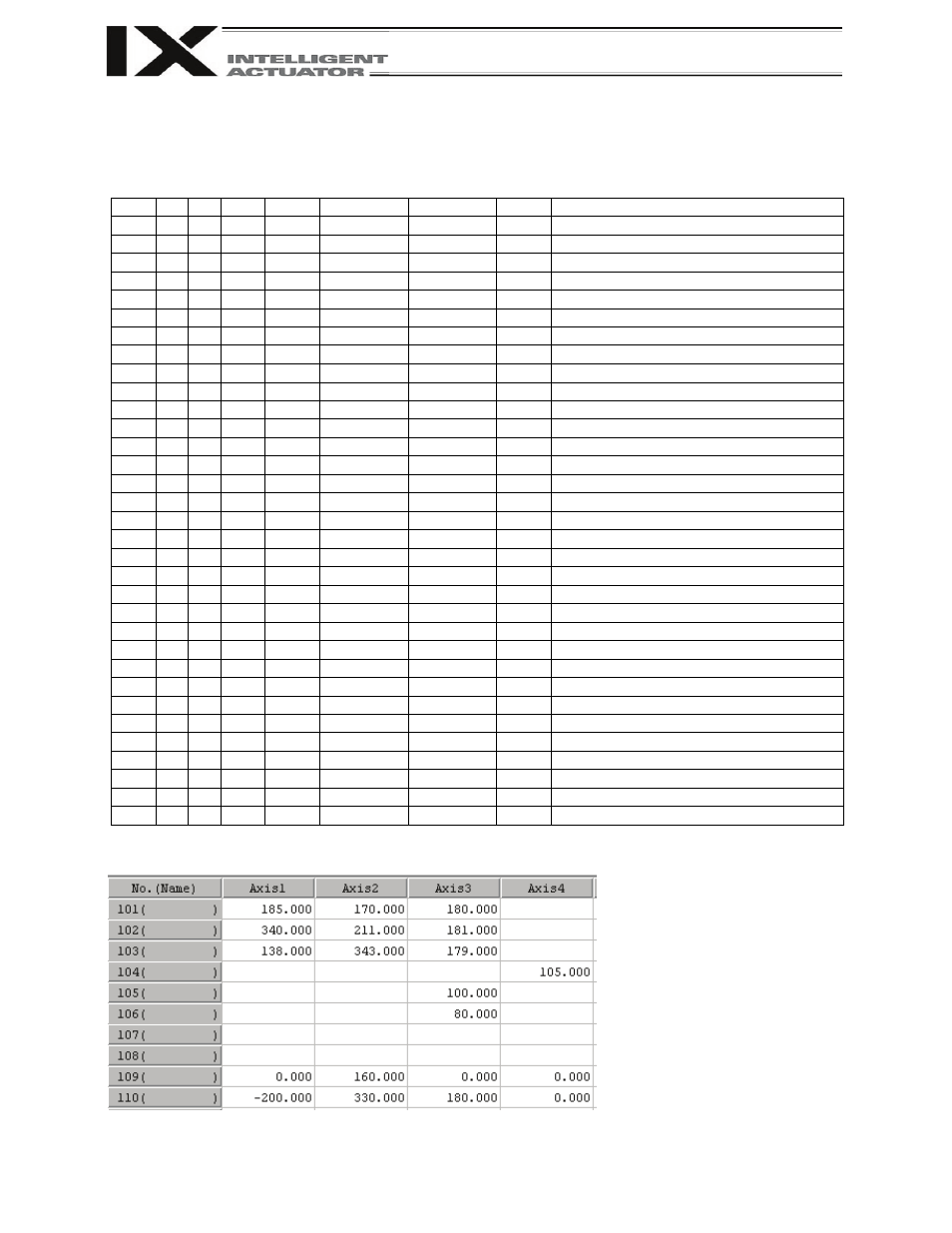

Position data (Stroke with arm length 500)

Reference-point position

PX-axis end point

PY-axis end point

Palletizing R-axis position

Arch/palletizing trigger position

Highest position (Z point)

Standby position

Pickup position