Optional, Optional paps position number – IAI America XSEL-KX User Manual

Page 230

214

Part 4 Commands

PAPS (Set palletizing positions)

Extension condition

(LD, A, O, AB, OB)

Input condition

(I/O, flag)

Command, declaration

Output

(Output, flag)

Command,

declaration

Operand 1

Operand 2

Optional

Optional

PAPS

Position

number

(Palletizing

position

setting type)

CP

Set palletizing positions based on 3-point teaching.

In operand 1, specify the first of the position numbers in which the coordinate values for start point, end point

in PX-axis direction and end point in PY-axis direction (hereinafter referred to as “Point Data”), which are

required when setting palletizing positions based on 3-point teaching, are stored.

In main application version 0.40 or later, palletizing positions can be set based on 4-point teaching, meaning

that the pallet surface can be set to any quadrangle other than square, rectangle or parallelogram.

If No. n is set as the position number in operand 1, point n represents the start point, point n+1 represents the

end point in PX-axis direction, and point n+2 represents the end point in PY-axis direction (in the case of 4-

point teaching, there is also point n+3 representing the end point). Fig. 1 shows the arrangement of palletizing

positions.

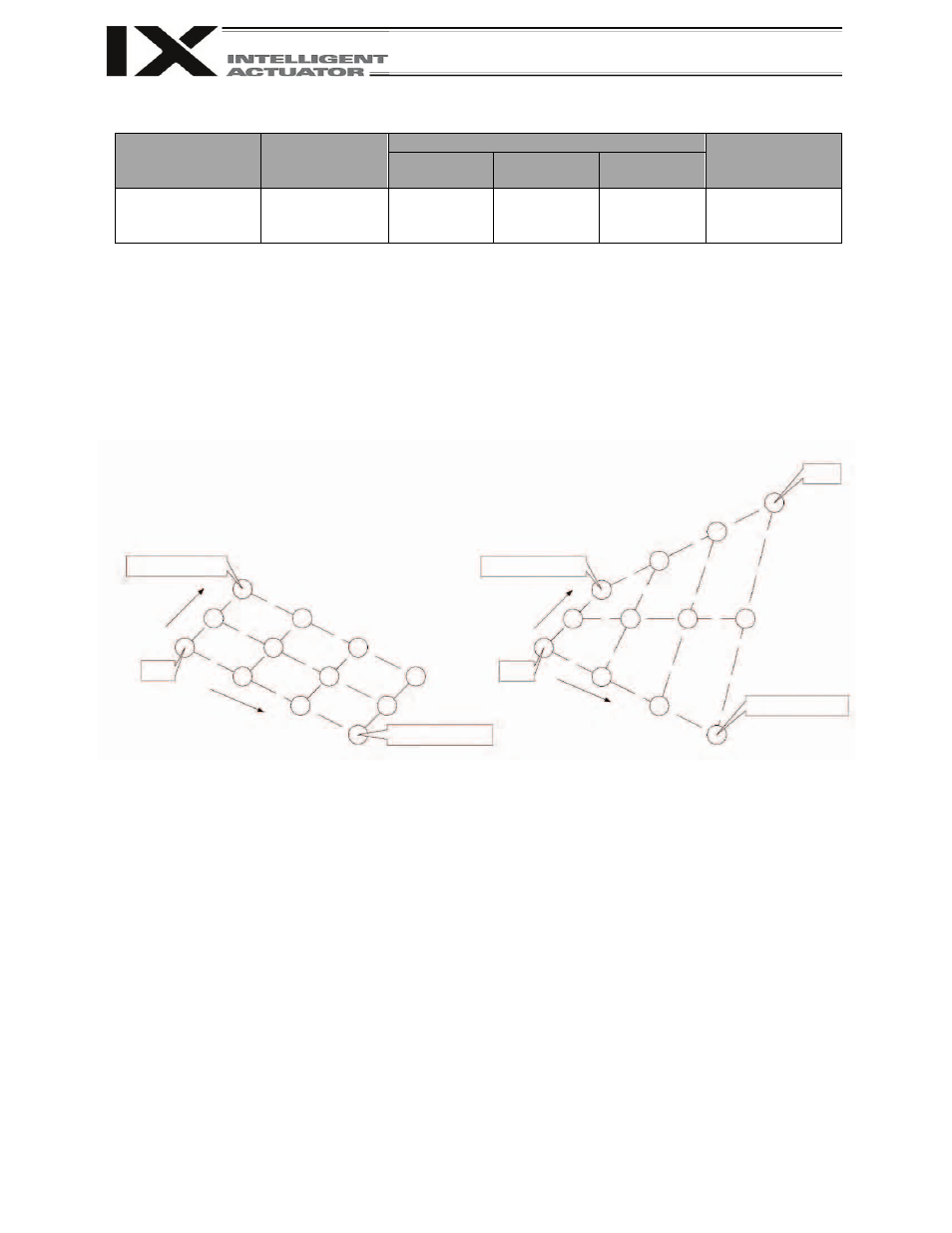

(a) 3-point teaching

(b) 4-point teaching

Fig. 1 Arrangement of Palletizing Positions

In main application version 0.40 or later specify the palletizing position setting type in operand 2.

[Palletizing position setting type]

0, or nothing is specified = 3-point teaching

Palletizing positions are arranged on a quadrangular pallet surface determined by the three points of

start point, end point in PX-axis direction and end point in PY-axis direction, as shown in Fig. 1-(a).

1 = 4-point teaching (planar type)

Palletizing positions are arranged on a planar quadrangular pallet surface determined by the four points

of start point, end point in PX-axis direction, end point in PY-axis direction, and point achieved by moving

the end point in parallel in the direction of the palletizing Z-axis (hereinafter referred to as “PZ-axis”) and

placing it on the plane determined by the aforementioned three points other than the end point, as shown

in Fig. 2-(a). Take note that if the three points other than the end point meet any of the conditions in

Table 1, the moving direction of the end point becomes different.

2 = 4-point teaching (non-planar type)

Palletizing positions are arranged on a quadrangular pallet surface determined by the four points of start

point, end point in PX-axis direction, end point in PY-axis direction, and end point, as shown in Fig. 1-(b).

Take note that whether the shape is planar or not varies depending on the point data of the end point.

End

point

End point in PX-axis

direction

Preferential axis

(PX-axis)

Start

point

PY-axis

End point in PY-axis

direction

End point in PX-axis

direction

Preferential axis

(PX-axis)

Start

point

PY-axis

End point in PY-axis

direction