IAI America XSEL-KX User Manual

Page 284

268

Part 4 Commands

B.

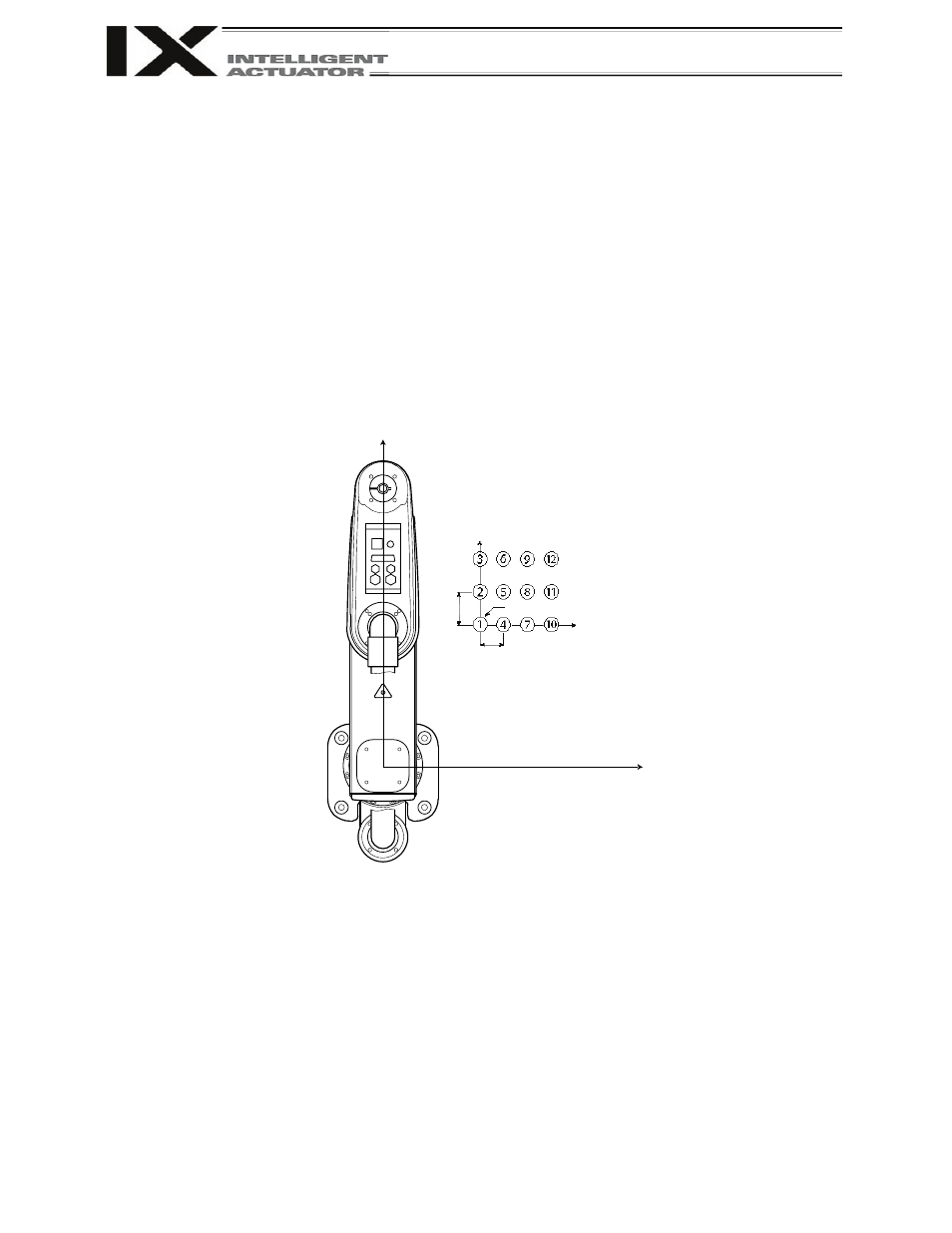

Method to set palletizing positions in parallel with the load coordinate system axes

Palletizing reference point: Store the position data of the start point (palletizing position No. 1) in a

position data field and specify the applicable position number using a

PAST command, as shown below.

Use a PEXT command to set the R-axis coordinate of a given palletizing

position.

Palletizing pitches:

Use a PAPT command to specify the pitches in the PX-axis and PY-axis

directions.

Palletizing axes:

Use a PASE command to specify the two axes, one representing the

PX-axis direction and the other representing the PY-axis direction, to be

used in palletizing.

(An actuator axis number parallel with the preferential axis (PX-axis) and another perpendicular to

the preferential axis)

PAST

100

Teach position data No. 100 as the start point.

PAPT

45

30

The PX-axis direction pitch is 45 mm and the PY-axis direction

pitch is 30 mm.

PASE

2

1

Set axis 2 (Y-axis) as the preferential axis (PX-axis) and axis 1

(X-axis) as the axis perpendicular to the preferential axis.

(Note) When the palletizing axes, palletizing pitches and palletizing reference point are

used, the PX-axis and PY-axis must be parallel with the load coordinate system axes

and crossing with each other. In the example shown above, load coordinate system

No. 0 (base coordinate system) is selected.

Select either method A or B for each palletizing setting.

PX

-ax

is

di

rec

ti

on

pi

tc

h

45

30

Teach position data No. 100.

Xb

PY-axis direction pitch

Yb