D1 d2, D3 d4 d5 – Rockwell Automation 284 ArmorStart User Manual User Manual

Page 443

24V DC Control Design Considerations

F-3

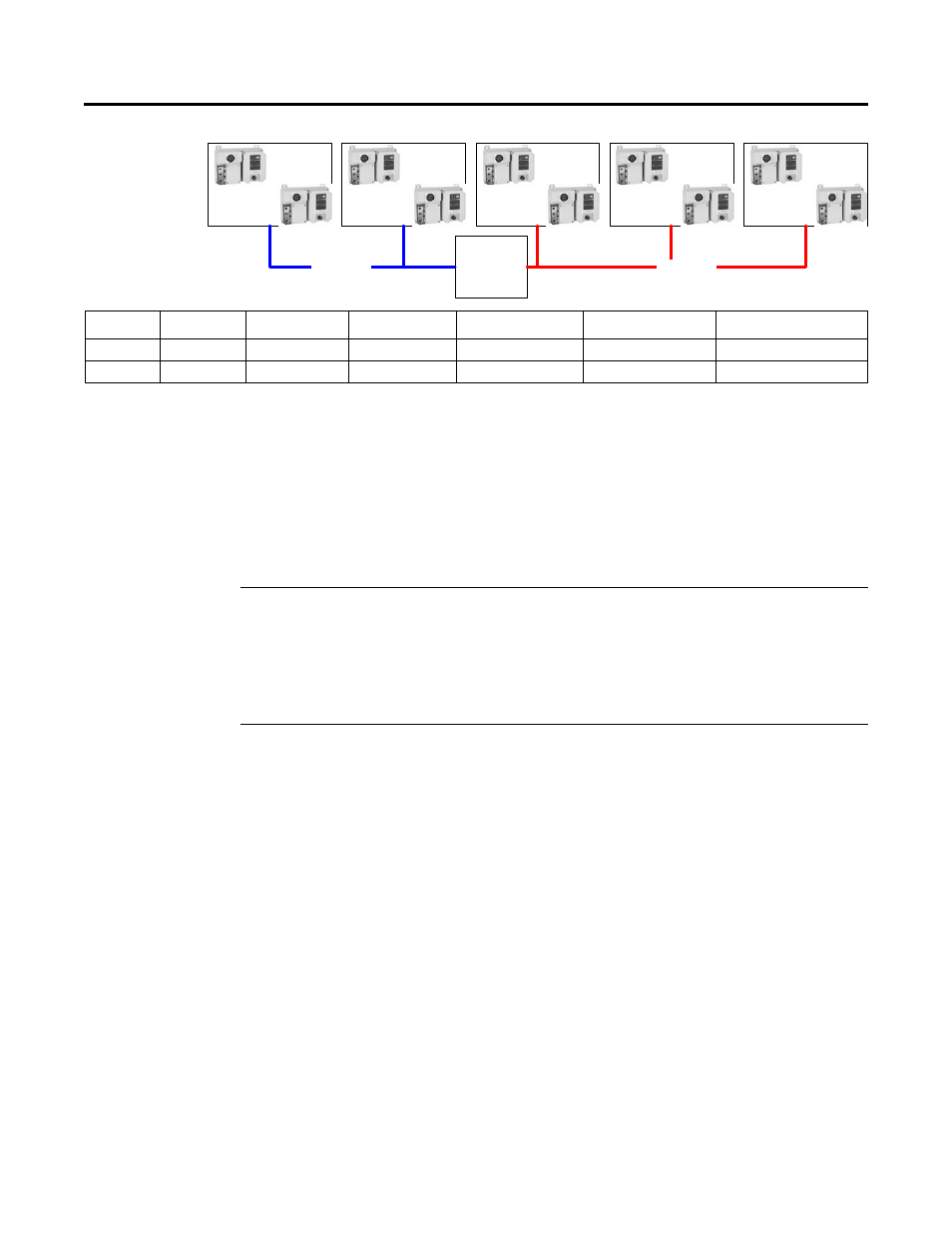

Figure F.3 Centrally Located Power Supply Distribution

Therefore, both runs can be #14 AWG. The controllers on section 3

are considered to have no length since the power supply is very close

to the units.

24V DC Power Supply Capacity Sizing

The 24V DC power supply current rating required for an ArmorStart

system can be calculated by the following formula:

Example – Calculation of 24V DC Power Supply Requirements

Size the power supply for Example 1 – Conveyor Line Configuration.

Each starter has a .1A customer load.

I supply = 10*.17 +5*.710 + 5*.063 + 0*.425 + 10*.1

I supply = 1.7+ 3.55 + .315 + 0 + 1 = 6.57A

Conveyor

Section 1

Conveyor

Section 2

Conveyor

Section 3

Conveyor

Section 4

Conveyor

Section 5

24 vDC

Power

Supply

# 14 AWG

# 14 AWG

D1

D2

24V DC

Power

Supply

D3

D4

D5

Distance 1

Distance 2

Distance 3

Distance 4

Distance 5

Equivalent Distance

Run 1

+ 50 ft (15 m) + 50 ft (15 m) * 2

150 ft (46 m)

Run 2

+ 0 ft (0 m) * 3

+ 50 ft (15 m) * 2

+ 50 ft (15 m)

150 ft (46 m)

I supply = N*.25A + K*3A + J*.3A + L*.425A + M

N =

No. of 280/281 ArmorStart units with the HOA plus 283 ArmorStart units

K =

No. of ArmorStart (280,281and 283) that will be commanded start simultaneously, K = 1 minimum

J =

No. of ArmorStart (280,281and 283) that will be commanded to hold in at any time

L =

No. of 284 ArmorStart Units

M =

Current drawn by customer loads