Rockwell Automation 284 ArmorStart User Manual User Manual

Page 442

F-2

24V DC Control Design Considerations

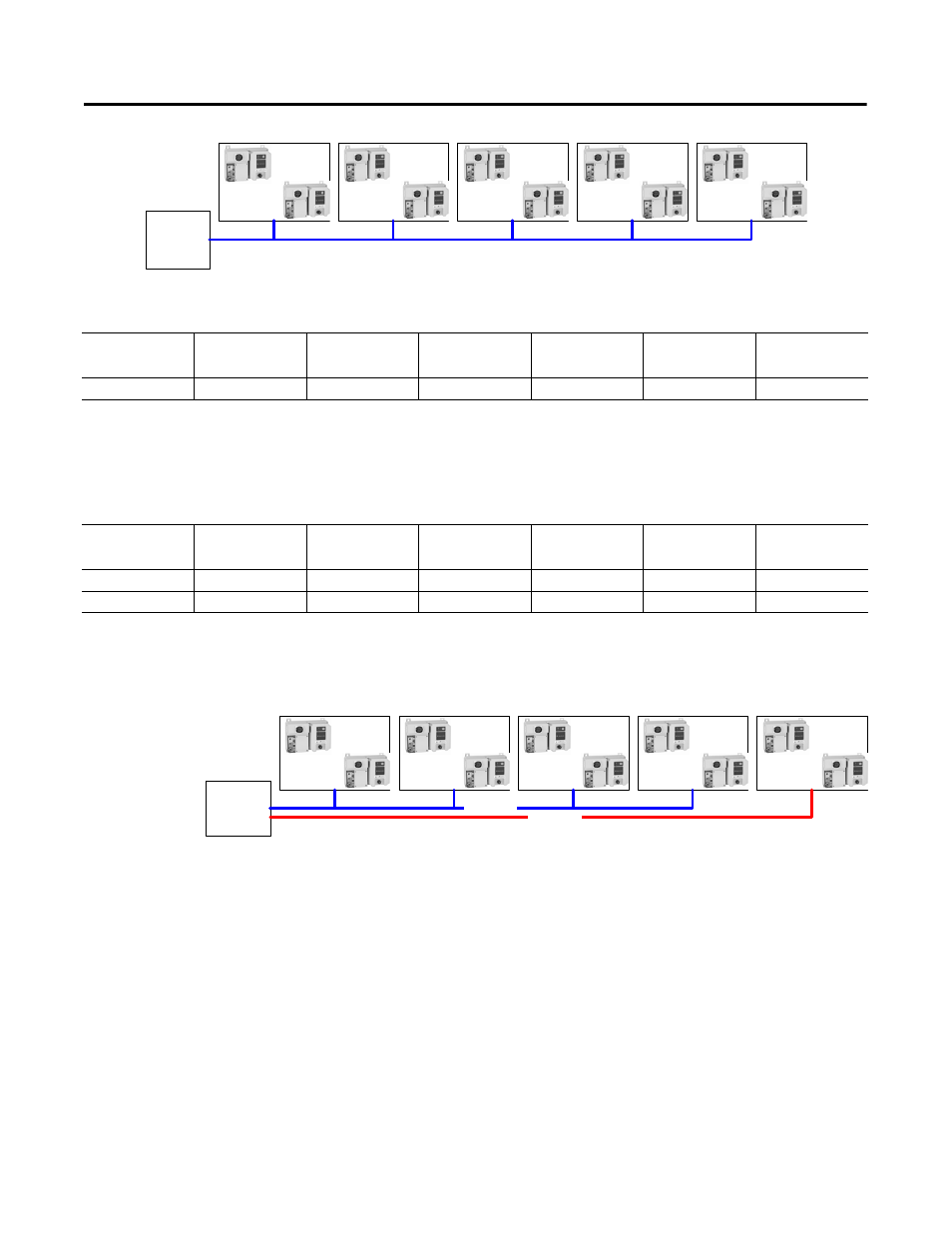

Figure F.1

Let us calculate the effective wire lengths.

Based on this calculation, there is no wire gauge that can be taken 750

feet, so the fifth section is required to have its own run.

Example 1 Re-calculated with section 5 having its own power feed

Therefore, Run 1 needs to be #10 AWG, while Run 2 can be either

#12 AWG or #10 AWG.

Figure F.2 Two-Run Wiring Solution

Example 2

Centrally locate the power supply in Example 1 – Conveyor Line

Configuration.

Conveyor

Section 1

Conveyor

Section 2

Conveyor

Section 3

Conveyor

Section 4

Conveyor

Section 5

24 vDC

Power

Supply

D1

D2

D3

D4

D5

24V DC

Power

Supply

Distance 1

Distance 2

Distance 3

Distance 4

Distance 5

Equivalent

Distance

Run 1

+ 50 ft (15 m) * 5

+ 50 ft (15 m) * 4

+ 50 ft (15 m) * 3

+ 50 ft (15 m) * 2

+ 50 ft (15 m) * 1

= 750 ft (229 m)

Distance 1

Distance 2

Distance 3

Distance 4

Distance 5

Equivalent

Distance

Run 1

+ 50 ft (15 m) * 4

+ 50 ft (15 m) * 3

+ 50 ft (15 m) * 2

+ 50 ft (15 m)

= 500 ft (152 m)

Run 2

+ 50 ft (15 m)

+ 50 ft (15 m)

+ 50 ft (15 m)

+ 50 ft (15 m)

+ 50 ft (15 m)

= 250 ft (76 m)

Conveyor

Section 1

Conveyor

Section 2

Conveyor

Section 3

Conveyor

Section 4

Conveyor

Section 5

24 vDC

Power

Supply

# 10 AWG

# 12 AWG

24V DC

Power

Supply