Rockwell Automation 284 ArmorStart User Manual User Manual

Page 300

14-6

Troubleshooting

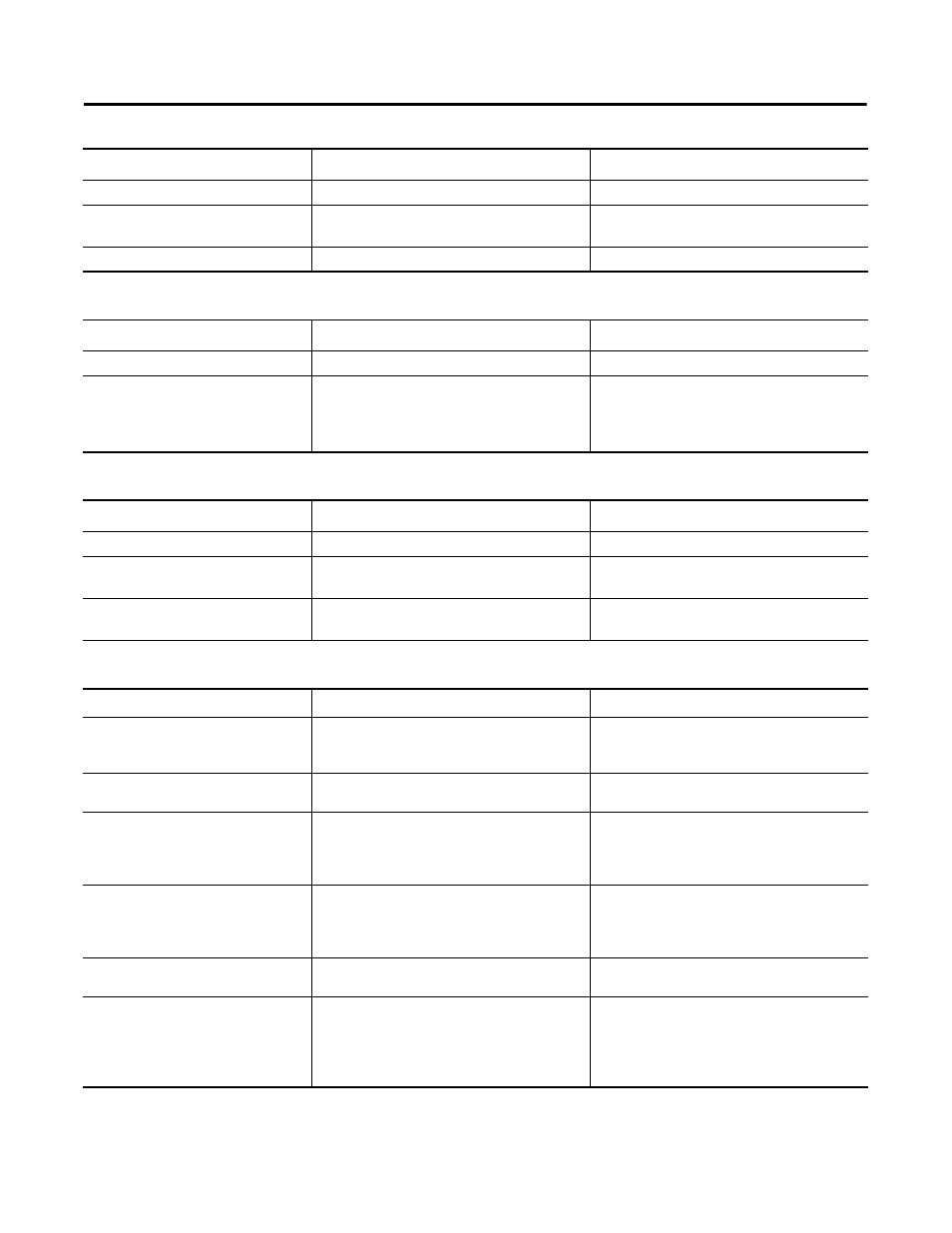

Table 14.4 Motor Will Not Start – No Output Voltage to the Motor

Table 14.5 Motor Rotates (but does not accelerate to full speed)

Table 14.6 Motor Stops While Running

Table 14.7 Miscellaneous Situations

Display

Possible Cause

Possible Solutions

Fault displayed

See fault description

See Table 14.3 addressing fault conditions

Display is blank

Control voltage is absent

Check control wiring and proper polarity. Correct if

necessary

Starting

Two or three power phases are missing

Check power system

Display

Possible Cause

Possible Solutions

Fault displayed

See fault description

See Table 14.3 addressing fault conditions

Starting

Mechanical problems

Inadequate Current Limit setting

Failed control module

Check for binding or external loading and correct

Check motor

Adjust the Current Limit level to a higher setting

Replace control module

Display

Possible Cause

Possible Solutions

Fault displayed

See fault description

See Table 14.3 addressing fault conditions

RUN LED is blank

Control voltage is absent

Failed control module

Check control wiring and correct if necessary

Replace control module

Starting

Two or three power phases are missing

Failed control module

Check power system

Replace control module

Display

Possible Cause

Possible Solutions

Motor current and voltage fluctuates with

steady load

Motor

Erratic load

Verify type of motor as a standard squirrel cage

induction motor

Check load conditions

Erratic operation

Loose connections

Shut off all power to controller and check for loose

connections

Accelerates too fast

Starting time

Initial torque

Current limit setting

Kickstart

Increase starting time

Lower initial torque setting

Decrease current limit setting

Lower kickstart time or turn off

Accelerates too slow

Starting time

Initial torque

Current limit setting

Kickstart

Decrease starting time

Increase initial torque setting

Increase current limit setting

Increase kickstart time or turn off

Motor stops too quickly with Soft Stop

Time setting

Verify the programmed stopping time and correct it

or increase

Motor stops too slowly with Soft Stop

Stopping time setting

Misapplication

Verify the programmed stopping time and correct if

necessary

The Soft Stop is intended to extend the stopping

time for loads that stop suddenly when power is

removed from the motor