8monitoring functions – Lenze i700 User Manual

Page 244

8

Monitoring functions

8.4

Monitoring of the motor utilisation (I²xt)

244

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Parameter setting of the time constant and the influence of the winding on motors of other

manufacturers

When the influence of the winding is activated, the i²xt monitoring becomes more sensible as if only

the influence of the laminated core would be used for monitoring purposes.

The necessity to activate the influence of the winding rises with the increasing utilisation of the

motor overload capacity. It also rises with applications where the motor is at standstill for longer

periods or cyclically and a load ≥ permanent standstill current is applied.

For determining the values for the thermal time constant, try to get the data from the motor

manufacturer. If this is not possible, you can use the data of a comparable Lenze motor.

Conditions for comparability are similar values in case of the following motor features:

• Square dimensions of the motor (active part)

• Length of the active part (if available)

• Permanent standstill current Io [A_RMS]

• Peak current/overload capacity [A_RMS]

• Copper resistance of the winding at 20 °C [Rphase]

Example:

When the "MCS09F38" Lenze motor is selected from the motor catalogue of the »PLC Designer«m

the following values are displayed:

• Thermal time constant of the winding = 126 s

(or

for axis B)

• Influence of the winding = 27 %

(or

for axis B)

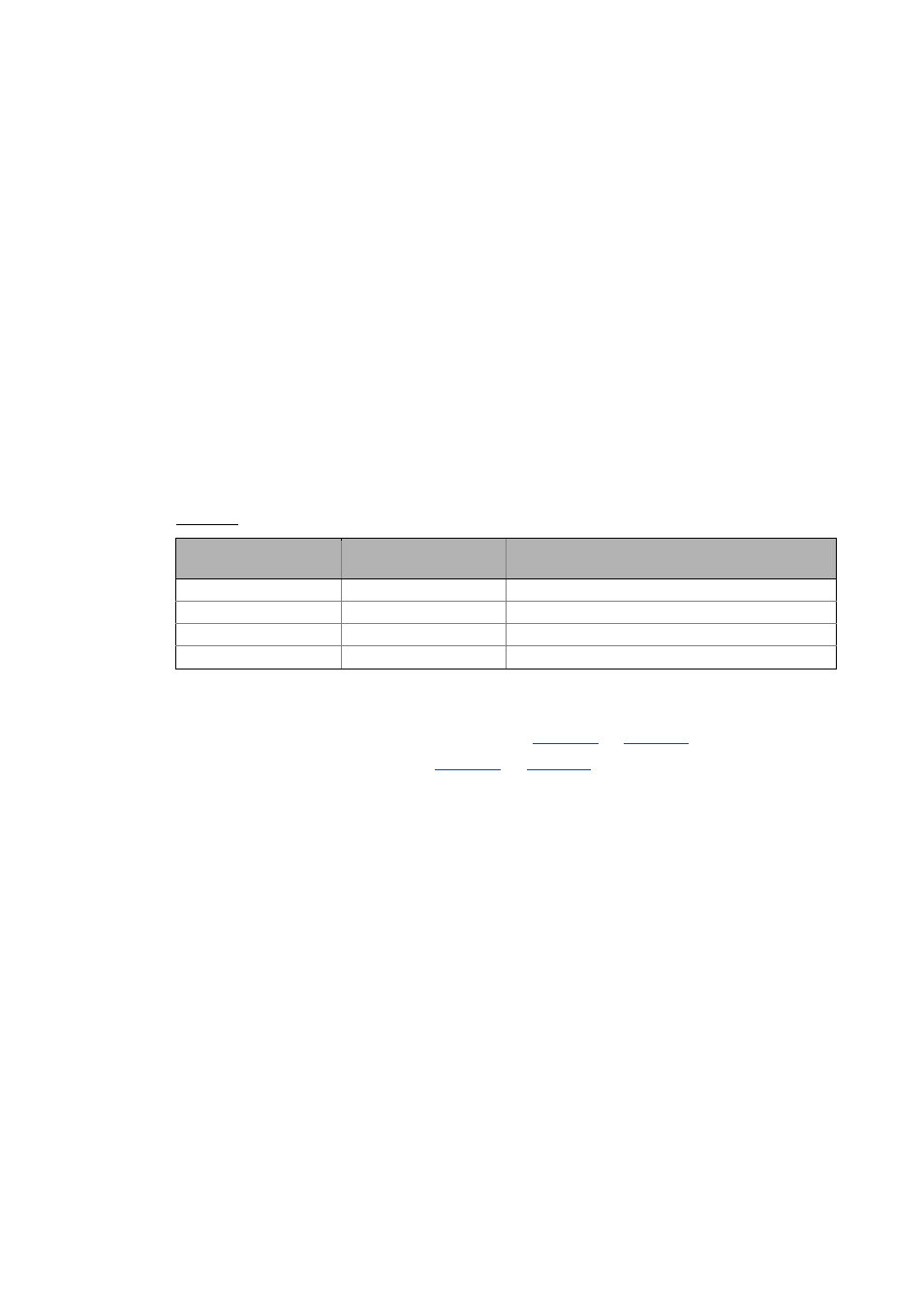

Motor features

Data of the third-party

motor

Data of a comparable Lenze motor (from motor

catalogue)

Square dimension

95 mm

MCS09xxx = 89 mm

Standstill current

2.2 A

MCS09F38 = 3.0 A

Peak current

7.3 A

MCS09F38 = 15 A

Phase resistance

5.1 Ohm

MCS09F38 = 5.2 Ohm